The wheel hub, also known as the rim, is the barrel-shaped, center-mounted part of the tire that is used to support the tire. Common car wheels include steel wheels and aluminum alloy wheels. Steel wheels have high strength and are often used in large trucks; however, steel wheels are heavy in quality and have a single shape, which does not conform to today’s low-carbon and fashionable concepts, and is gradually being replaced by aluminum alloy wheels.

The wheel hub, also known as the rim, is the barrel-shaped, center-mounted part of the tire that is used to support the tire. Common car wheels include steel wheels and aluminum alloy wheels. Steel wheels have high strength and are often used in large trucks; however, steel wheels are heavy in quality and have a single shape, which does not conform to today’s low-carbon and fashionable concepts, and is gradually being replaced by aluminum alloy wheels.

The Advantages Of Aluminum Alloy Wheels

- Compared with steel car wheels, the advantages of aluminum alloy wheels are obvious: the density is small, about 1/3 of steel, which means that the same volume of aluminum alloy wheels will be 2/3 lighter than steel wheels. Statistics show that the quality of the vehicle is reduced by 10%, and the fuel efficiency can be increased by 6% to 8%. Therefore, the promotion of aluminum alloy wheels is of great significance for energy saving, emission reduction and low-carbon life.

- The thermal conductivity of aluminum is high, while that of steel is low. Therefore, under the same conditions, the heat dissipation performance of aluminum alloy wheels is better than that of steel wheels.

- Fashion and beautiful. Aluminum alloy can be strengthened by aging, and the cast aluminum alloy wheel hub without aging treatment has low strength and is easy to be processed and formed.

The Structural Analysis Of Automobile Aluminum Alloy Wheel

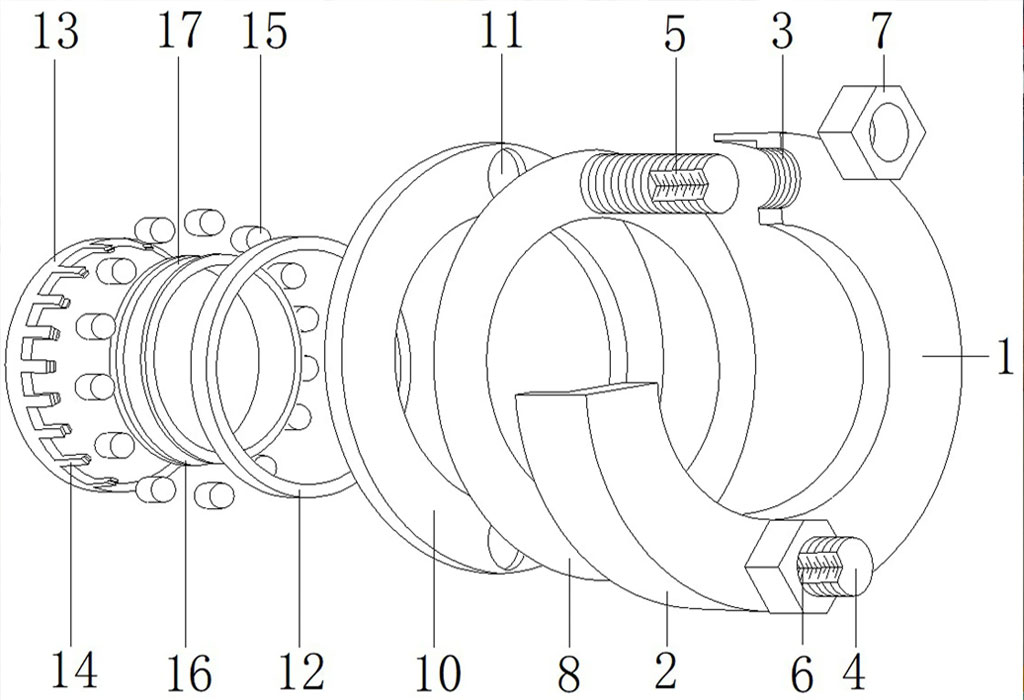

In order to meet the needs of the use function and the market, the aluminum alloy wheel has a variety of structural designs such as integral and multi-piece combination; in terms of appearance, there are various shapes such as wide spokes, narrow spokes, multiple spokes, and few spokes. . For safety reasons, the appearance and structural design of aluminum alloy wheels must meet the requirements of safety and use functions. For ordinary passenger cars, one-piece aluminum alloy wheels are sufficient to meet their performance requirements. The structure of the car wheel hub is shown in Figure 1, which can be divided into two parts: the rim and the wheel hub. The specific functional analysis of each part is shown in the figure below.

The Performance Requirements Of Automobile Aluminum Alloy Wheels

There are many types and structures of aluminum alloy wheels, and their requirements vary according to vehicle types and models, but both strength and precision are the basic common requirements. According to market research, the wheel hub should have the following properties:

- The material, shape and size are correct and reasonable, which can give full play to the function of the tire, interchange with the tire, and have universality;

- When driving, the vertical and lateral vibrations are small, and the unbalance and inertia moment are small;

- Under the premise of light weight, it has sufficient strength, stiffness and dynamic stability;

- Good separability from axles and tires;

- Has excellent durability;

- Its manufacturing process can meet the requirements of stable product quality, low cost, multiple varieties, and mass production.

The Forming Method Of Automobile Aluminum Alloy Wheel

At present, the production methods of aluminum alloy wheels mainly include casting method, forging method, stamping method and spinning method. my country’s aluminum alloy wheel manufacturing is still dominated by low-pressure casting, and some advanced manufacturing processes have not yet been adopted. However, the manufacturing technology of aluminum alloy wheels is constantly developing. In order to improve its performance, it is now developing towards the direction of extrusion casting (liquid die forging) and semi-solid die forging. BE-CU Co., Ltd. specializes in the sales of testing equipment for automotive bright machining aluminum wheels. For automobile wheel casting, it is necessary to test whether the hydrogen content of the molten aluminum meets the standard in a low-pressure environment. The aluminum liquid hydrogen detector, aluminum water degasser, and electric powder spraying refining tank produced and sold by be-cu.com business partner just meet this need.

Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products