Have you ever heard about a product prototype? It seems like a very technical and specific word, but the truth is that it is so familiar that you can’t even imagine it. Due to this, in this note we will tell you what a prototype of a product is, what it is for and what the guidelines are for making one.

A fundamental part of the development of a product or rapid prototyping service is born as a result of a prototype. In fact, the device you are using to read this text arose from prototyping planning and extensive project execution. Therefore, today you will learn how to design a product prototype, the characteristics of product prototypes and the steps to carry out a prototype.

In addition, we will share some examples of innovative product prototypes so that you can be inspired by your own product prototype creation.

Have you ever heard about a product prototype? It seems like a very technical and specific word, but the truth is that it is so familiar that you can’t even imagine it. Due to this, in this note we will tell you what a prototype of a product is, what it is for and what the guidelines are for making one.

A fundamental part of the development of a product or rapid prototyping service is born as a result of a prototype. In fact, the device you are using to read this text arose from prototyping planning and extensive project execution. Therefore, today you will learn how to design a product prototype, the characteristics of product prototypes and the steps to carry out a prototype.

In addition, we will share some examples of innovative product prototypes so that you can be inspired by your own product prototype creation.

What Is The Prototype Product?

A product prototype is a limited representation of a product design that allows the parties responsible for its creation to experiment, test it in real situations, and explore its use. A product prototype can be anything from a piece of paper with simple drawings to a complex design drawn up in 2D or 3D animation software.1. What is a product prototype for?

They are useful for communicating, discussing and defining product ideas between designers and responsible parties. A prototype is of great importance in the initial phases of its development, specifically, during conceptual design.2. What is the goal of prototyping a product?

Prototypes support the work by evaluating products, clarifying user requirements, and defining alternatives. In this way, it can be failed quickly, but at a very low cost.3. What is needed to prototype a product?

Different materials are used and do not resemble the final product. Their advantage is that they are cheap, simple and easy to produce. Prototyping a product connects us with other interesting questions. One of them is knowing how to apply the power of execution and a very particular way of working: that of executing to think.

The prototype of a product does not need to have all the functionalities that we aspire to reach. These are incorporated as the user demands them or when there are important tests for the development of a product or service.

Prototyping a product connects us with other interesting questions. One of them is knowing how to apply the power of execution and a very particular way of working: that of executing to think.

The prototype of a product does not need to have all the functionalities that we aspire to reach. These are incorporated as the user demands them or when there are important tests for the development of a product or service.

Why Choose Rapid Prototyping Process?

Prototyping or the development of a prototype is the fourth of the phases within a process of Design Thinking and innovation centered on people. It is the moment in which makers with the skills to “land” ideas and work with their hands, carry out the design of a product prototype to make tangible the proposals that have arisen during the planning of a project. This “landing of ideas” will allow the user not only to imagine proposals, but also to be able to touch them. Therefore, design thinking and its relevance in the prototype of a product is essential to implement an action-oriented methodology. Some of the advantages of a Design Thinking process to know how to make a prototype are:- His ability to move us forward.

- The convergence of all the ideas on which they have worked.

- The creation of a tangible reality that can be built in various ways depending on the product prototype that is being made.

- The possibility of carrying out tests that include Design Thinking with prototyping and testing with users.

The Types Of Rapid Prototypes

As you have noticed, the development of prototypes for a product is a practical and “inexpensive” way to test hypotheses about the viability of a product or service. When you think about how to prototype, chances are only one type of prototype comes to mind. However, in the product design process, there are three different types of prototypes, each of them adapted to different scenarios or situations.1. Iterative prototyping

One of the design techniques focused primarily on user experience is iterative prototyping. This method consists of creating a prototype starting from the product design. The designers select a group of users who are in charge of experimenting with the usability and functionality of the prototype and, later, the product development team reviews and evaluates the results. After the tests with said prototype have finished, the researchers return to design a new model for the execution of new tests; hence, its iterative prototyping name. Iterative product or rapid prototyping service is a method that allows you to quickly identify complex design-related issues, however, creating many prototypes throughout the process can lead to budget issues if too many tests are run.2. Parallel prototypes

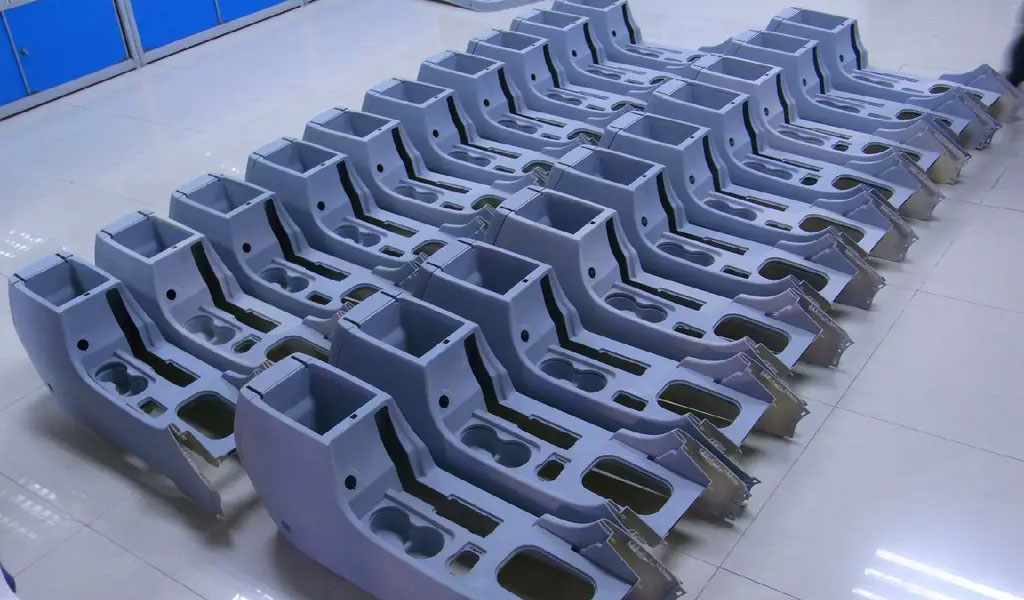

The second of the types of prototypes that we will teach you in this section are parallel prototypes, a method that is based on the creation and comparison of different design concepts of the same product simultaneously before elaborating a physical prototype. After the design teams develop their concepts independently or not, they are compared and the best of each is chosen for prototyping. Building parallel prototypes is useful when projects are large, as they often have the potential to address high risk factors. Although the parallel prototyping technique offers ample opportunities to unleash creativity, it can be costly due to multiple factors: human resources, raw materials, etc. So it is recommended that you consider the product or service that you want to introduce to the market and what is the best type of prototype that will allow you to get where you want.3. Rapid Prototyping(Include 3D Printing,Cnc Machining,Sheet Metal,Laser Cutting etc.,)

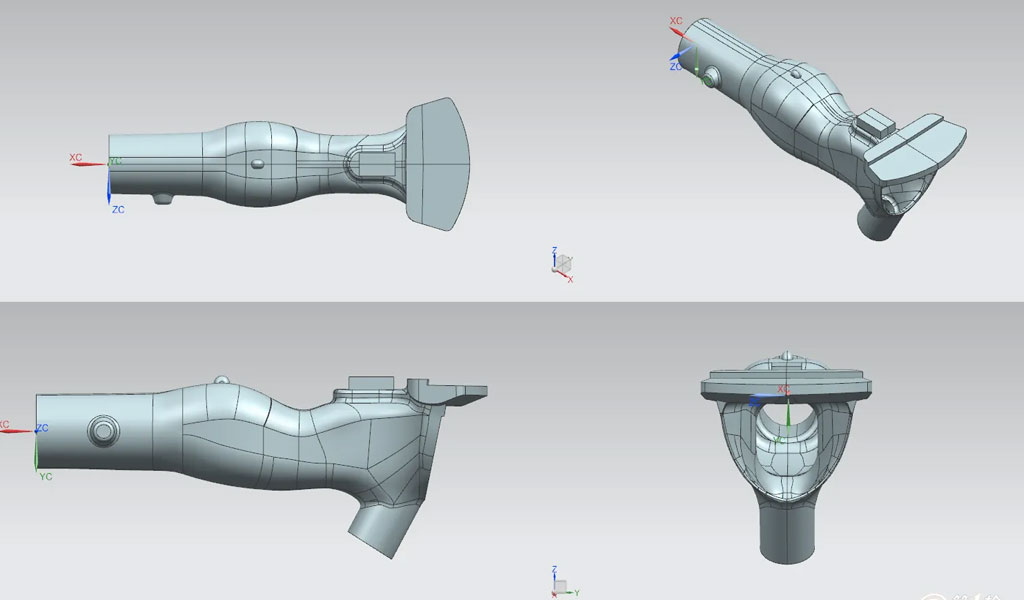

Recently, a prototyping method of product design has proliferated that combines some of the features of iterative prototyping with the use of technology, rapid prototyping. This technique takes advantage of 2D and 3D software, such as CAD design software, and 3D printing for prototyping processes. The ease of data transfer between a computer and a 3D printer offers unimaginable advantages in prototyping a product. You can develop usability and functionality tests quickly, effectively and economically. And while prototyping a product with the above methods also proves to be effective, rapid prototyping can create a new model of the product in a very short time and speed up the market launch. So you may be wondering: what type of prototype is the best for my design? In reality, affirming that a prototyping method is better than the previous one is somewhat subjective, since factors such as: the type of company, the characteristics of the product and the possibilities of construction come into play. However, as we have mentioned, the speed, price and effectiveness of the technology are decisive when choosing the appropriate prototyping method for your product.The Categories Of Prototype

Making a prototype is not just about presenting a “opener” of your product. It is, in essence, about showing your audience your idea embodied in reality. To do this, there are 4 categories in which you can classify your prototype in question:1. Visual prototype

The visual prototype is one in which the purpose is to show, before the public, the size and dimensions of the final product. Mainly, in terms of aesthetic proportions, size and weight of the item in question. It does not serve to demonstrate the functionality of the product, not even the materials with which it will be released. You can even include materials that are not the final model (a 3D digital model even serves as a visual prototype!)2. Proof of concept

Here we have the opposite of the visual prototype: the proof of concept is a model that is intended to demonstrate the feasibility of the product and its operation. Usually, to carry out a proof of concept, materials that are readily available are used. It is not about demonstrating the complete functionality of the article, far from it, but rather demonstrating how viable the realization of the product can be.

3. Presentation prototype

Here we find a version of the product that is prepared and ready to be presented. In this case, it looks similar to the final product and is functional. It is the prototype that is usually shown to investors and potential clients, so that they have an idea of the final result. And, of course, it seeks to use custom materials and manufacturing techniques.4. Pre-production prototype

For this type of category, we find a modified variant of the presentation prototype. Basically, they have similar functionality to the ones mentioned above, although they are built based on production-ready materials and techniques. This type of prototype is the one that is usually the reference to establish the way in which the same article should be mass-produced. If you think the prototype categories look more like “stages,” you may be right. However, it may happen that a product does not always go through one of these categories. You can go from a paper and tape proof of concept to a prototype ready for mass production. As you can see, the categories of a product prototype mainly go through two themes: complexity and function. Depending on your item, it will be up to you to decide what you want to show investors and potential buyers. What we do remind you of is that it is an important resource, which will help you to consolidate your idea as something tangible and real.When To Prototyping A Product?

learning by doing is the motto of user-centered designers or UX designers and one of the current educational trends. Thanks to, for example, the fundamentals of UX/UI design or the application of usability tests, user feedback is obtained as quickly as possible. So, it is important that you make the prototype of a product when you feel that it is ready to be tested (initial prototype) or when you already want to launch your product or service (final prototype). The prototype of a product or service helps to:- Quickly test and validate new ideas.

- Understand the keys to user interaction.

- Improve the user experience and iterate on it.

- Demonstrate the capacity of a product (demoing).

- Validate appearance design detail: define the intent of sizes, colors, shadows, etc.

1.The Types of product prototypes

It is essential to approach the prototypes of a product from two points: What do they explore? How do they evolve and what is their result? In the first point, referring to exploration, there are two main classes of prototypes:- A behavioral prototype, which, as the name implies, focuses on exploring specific responses or behaviors of the system.

- A structural prototype, which explores some technological and architectural aspects.

- An exploratory prototype, which is scrapped when finished, also known as a scrap prototype.

- An evolutionary prototype, which gradually evolves into the real system.

2. Prototype of a product versus minimum viable product

The difference between a product prototype and a minimum viable product is that a product prototype is a proof of concept that analyzes the feasibility of the solution. On the other hand,minimum viable product is the materialization of the value proposition with the minimum possible functionalities. Most product prototypes are designed to answer questions like can we build it? and an minimum viable product must always answer the question: what have we validated or invalidated?How do you make a prototype of a product?

Once the prototype of a product is understood, proceeding to its creation begins with the concept that is sought to materialize. To accomplish this task, let’s first look at what it takes to make a prototype and then the steps to make a prototype of a product.What does it take to prototype a product?

Once you have defined the type of product prototype that will be most useful to you, based on the views you have chosen (what they explore and how they evolve), you must select the necessary materials for the elaboration of a product or service prototype.Paper prototype

It consists of a sketch or drawing. In English it is said “sketching” and allows to make a flow of the user’s interaction with the product. Doing a quick sketch as a first approximation is highly recommended. A good idea to know how to make a prototype is to use graphs or maps to focus your ideas, organize them and draw correct conclusions. Mind maps, for example, can be of great help in helping you in this process. Therefore, we invite you to download and use these mental map templates with which you will be able to order the phases of a prototype and not lose direction in its execution.Digital prototype

This is something that takes a little more effort than prototyping on paper, but it will help you dig deeper into how to design digital products, looking at the design of the product’s appearance. This type of product prototype, above all, will allow you to validate the reactions of potential customers, since you will show them something with a realistic appearance, making them believe that it is a real product.Native prototype

This is highly desirable in the case of apps, since if we really want to give the user the feeling that it is a good app, we must include the interaction with the device (gyroscope, accelerometer, speakers, camera, microphone and GPS) within the prototype. ) that simulate a realistic experience.How Is The Prototype Of A Product Tested?

While it is true that the prototyping methodology allows companies to save large amounts of money, it is just as important to understand that it is not only about how to make a prototype, but also how to test the prototype of a product. Is it really going to work and meet the expected objectives? In this sense, the prototype must convey exactly what the product or service will do, as well as the final appearance so that you can obtain the appropriate feedback from the interested parties. This step shouldn’t involve a lot of time or resources that you would need to build the actual end product. For example, suppose you are in the fashion industry. If what you want is to launch a new clothing line, then here you must ask yourself two fundamental questions to test the prototype of your product: what will its function be? What will its shape be? Of course, you can always go to a designer specializing in product prototypes to carry out the tests. What he or she will do is look for models to test the new designs and draw their conclusions. Logically, it will be an investment expense that you may prefer to avoid. So how do you test a product prototype without first seeking expert opinion? A good starting point to assess the effectiveness of a product prototype, in this case, is to look at oneself and one’s social circle. Sometimes we are looking for answers outside when in reality we have them within us. Test yourself or yourself your first prototypes. Ask yourself if you would wear the clothing line you want to launch. If the product prototype passes the first step, then it’s ready for the next one: testing it out with your trusted family and friends. And we mention trust because we know that we don’t always get totally constructive criticism from everyone. Now, before presenting a prototype of a product to your trusted selection, prepare questions that will help you get their views. During the process, you can ask the following:- Do you like this product? Yes or no? Why?

- What do you like?

- What would you change? Mention minimum 3 characteristics, maximum 5.

- Would you use it?

- When would you use it?

- Would you recommend it? To who?

- Would you prefer it to other similar products on the market? Why?

- Do you think it is necessary?

- What defects do you find in the product?

How Do I Know If My Prototype Is Ready?

While the idea of prototyping a product is to subject it to extensive testing in order to make improvement decisions, there will be a point in the prototyping process where you will have to make a final decision. Remember that the goal of a prototype is to prevent any failure after it has been launched. However, you will agree that it is also important to know when our product is really ready. After tireless months of trials and tests, the time has come when your prototype will stop being a prototype to finally become a final product. Functionality details have been adjusted and accounts with an optimal product design for the user. Now what next? A prototype product that is truly ready to go to market offers the following characteristics:- The problem that was raised from the beginning was solved.

- The result obtained meets or exceeds expectations.

- It makes an important difference compared to similar products on the market.

- The best alternative that exists before the competition for its added value.

The Steps To Prototyping A Product

1. Make a sketch

The purpose of this phase is to have a diagram that visually captures what you have in mind. You can use low-resolution materials (cardboard, clay, Legos, etc.) or high-resolution materials, such as a 3D image or video. A sketch should show the finished product, the materials used, its dimensions, and its function.2. Create a 3D model

Although any available material can be used, this version provides several advantages. Through a 3D model you can visualize the prototype in a better way, modify it according to the results of the tests, make the necessary iterations until you obtain the ideal design and use product prototype design applications, such as Figma or Adobe XD.3. Carry out the proof of concept

In this part, the product is built from the sketch, the three-dimensional image or the diagram. It does not matter if it does not look like the finished object, because the objective is to find that the product prototype is functional.4. Seek to solve the problem posed

Before moving on to the final prototype, you need to make sure that the model is a viable solution. Don’t worry about the failed attempts, because these will give you several clues on how to move forward, either rephrasing the idea or discarding it.5. Run iterations

Once you figure out how it works in your product roadmap, the next step is to find the most efficient and marketable version. Ask yourself what could be improved, seek outside help or consult with acquaintances about how your product prototype works.6. Carry out experiments

It is essential to do all the necessary tests to confirm that the solution really works as expected. Lean on different validation methods or consider co-creations in which potential users give you feedback.7. Release the final prototype

After the performance validations, good user experience and tests, it’s time to launch your product prototype! This advanced stage requires more time, investment and cannot be tied to radical changes in the product’s performance. Do all the tests that are necessary so you don’t have to start from scratch.The Tips For Making A Product Prototype

We know that making a prototype from scratch can be complicated if you are a beginner, so at Crehana, we offer you the necessary tools so that the process can flow in the best way.

So that the process of making a product prototype can flow in the best possible way, follow the following tips:

We know that making a prototype from scratch can be complicated if you are a beginner, so at Crehana, we offer you the necessary tools so that the process can flow in the best way.

So that the process of making a product prototype can flow in the best possible way, follow the following tips:

1. Research your potential audience

This is key when creating a prototype. You must know your potential customer in depth: that target audience you want to reach through your product. If you do not know the profile of this person, it will be very difficult for you to respond to the demands of your client and your final product may end up going unnoticed in the market. The worst plan in the world. Knowing the needs of your client is the first step for any project you decide to undertake. Even if you are only presenting a rapid prototyping example.2. Conceptualize your project

The idea of the prototype is to seek to respond to a need, to an idea that emerged from the recesses of your mind (or from the minds of your work team). So you can use tools like the following:- Scenarios.

- Role play.

- Collage.

- Story board.

- Storytelling.

3. Design a list with the main characteristics

You will not be able to prevent your final product from achieving all the features that you had originally thought for it, since there may be certain material and cost restrictions that require you to cut various functions that are outside your initial budget. When designing your first product prototype, you should divide the features into 3 categories, which we will mention below:- Necessary: the essential characteristics for the proper functioning of the product.

- Moderately necessary: those features that are important for your product to stand out from the rest, but are not essential for it to work properly.

- Unnecessary: the most superficial characteristics of the article and that contribute little, beyond its aesthetics or visual appeal.

- At China Prototype Factory, we recommend that your product prototype have as many visual features as possible.

4. Sign Confidentiality Agreements and file patent applications

When you are developing your product prototype, it is likely that you may need a project team: a mechanic, 3D modeler, prototype designer… The issue is that if your idea is revolutionary, you can suffer a possible theft of intellectual property. And end up seeing your final product being developed by another company or an individual. Can you avoid this? Yes, totally. To prevent any copying or counterfeiting of your items, you can do one of the following:- File a patent application for your idea and product design.

- Ask your prototype development team to sign non-disclosure agreements (also known as NDAs).

- If you have no idea about how to apply for a patent or you are not clear about the procedure, we recommend that you choose to hire a specialist patent attorney, so that you avoid bad times with the leaking of your product prototype.

5. Consider the costs

At the time of creating the prototype, it is very common that you have a hard time balancing the cost-utility relationship. Your wish is that the product stands out for its functionality, but the idea is not to sell it at an exorbitant price, in order to achieve higher sales. If you only create exclusive and unattainable items for 95% of people, it is very likely that your product prototype will fail. And since we want to save you a bad time, we recommend that you ask yourself this question during the design of the project:- This stage in which the design is, is it necessary?

- What would be the most economical material to be able to manufacture the product, without losing its usefulness?

- Designing a product using plastic is not the same as designing a product using metal. Keep this information in mind when you decide to design your article.

6. Use general fabrication techniques

The steps that exist between the product prototype and the final version of your article usually involve procedures that, in the long run, generate cost overruns. What do we mean by this information? That, at the time of manufacturing your product, factories usually perform an industry standard technique. However, what if your product cannot be designed using the company’s manufacturing techniques? That the factory must implement personalized techniques, in addition to training its personnel to learn the procedure of the same. And this, unfortunately, can increase the cost of producing your final product. To avoid these drawbacks, take into account the type of manufacturing procedure for each part of your product prototype. If you find that any of your item’s features involve an overly customized production technique, you should consider removing it (if possible). If you need advice on the subject, you can find an expert, such as a mechanic or a prototype designer.7. Study your competition

To position yourself in the market with your prototype (in any type of market), you should look a little at what your competitors are doing to see what the public is demanding and better understand the functionality of a specific item. Be careful, we are not talking about plagiarism. We mainly mean that you see the products of your competition, study their designs and materials and visualize their advantages and disadvantages to apply them in your product prototype. This way you will know how you can improve public demand and, in addition, you will acquire ideas that will help you to develop your final product.Rapid Prototyping Factories From China

BE-CU China Rapid Prototyping Factories is affiliated to Pintejin Group Corporation (founded in 1995) and was established in 2019, located in Humen, Dongguan. It is a professional production rapid prototyping and industrial design company with high-end technology. The professional technical team is committed to providing customers with short-cycle and cost-saving verification and trial production solutions for the design and development of new products. From sample preparation to mass production, we have consistently adhered to the business philosophy of “quality, timeliness, and integrity”. Internationally competitive enterprises and make unremitting efforts! The company’s main business: prototype model, rapid mold manufacturing, aluminum cnc machining, SLA rapid prototyping prototype, CNC precision machining, rapid prototyping, complex mold, CNC prototype processing, precision aluminum parts processing; the product range covers auto parts, digital communication Products, household appliances, medical equipment, aviation industry, robotics, toys and 3D printing and other fields. Advantages: Focus on providing customers with “reduce cycle and cost-saving” R&D verification manufacturing and small batch product production solutions. Meet your customized needs of “multiple varieties, small batches, and fast delivery”.Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products