Build Better Aluminum Parts, Faster

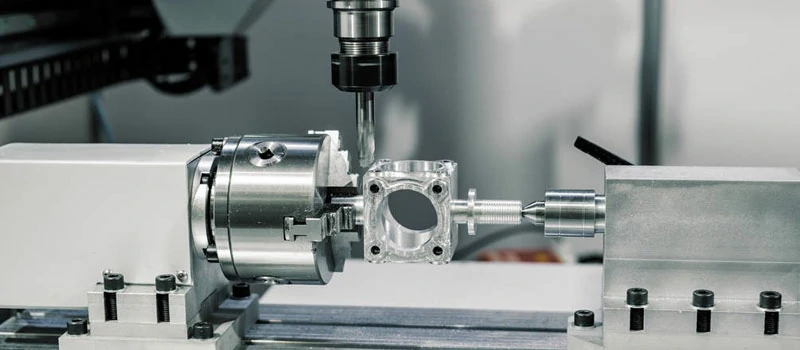

You don’t have to sacrifice quality for speed anymore. Be-cu can rapidly manufacture aluminum parts with precision tolerances as tight as +/- 0.0001 in via 5 Axis Machine.

As one of famous Aluminum CNC Machining manufacturers from China, Be-cu aluminum machining china company has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Aluminum material characteristics. So we can offer you the best machining aluminum solution according to your requirements of Aluminum parts and components.A variety of machines offer 5-axis, 3-axis, and 4-axis functionality. See prototype features below

- Volume: 1-20 or more parts

- Estimate: within 24 hours

- Lead time: 3 days minimum;100000+machined parts each month

- 100+CNC machines,Hand Metrology, Laser & CMM Inspections

- Standard tolerance: +/- 0.1mm

We have been a quick-turn and reliable online manufacturer and supplier for more than 30 years and we are an ISO 9001:2015 & ITAF 16949 certified aluminum cnc machining expert, always bringing demanding and OEM aluminum parts with high accuracy and precision.Creating precision aluminum components with an outstanding surface finish is possible with our aluminum cnc machining capabilities.No matter how complex the aluminum parts, each step will be executed with a rigorous attitude, to deliver exceptional aluminum cnc machining components that demonstrate the highest quality standards. Even though any problems during the process, we’ll keep running the job and make adjustments until all the issues are addressed. If you require a well-established and cost-effective aluminum cnc machining company to take over your project, Be-cu can achieve your expectation.If you are willing to work with us or want to know more details, welcome to contact us via email.

- Why Choose us

- Aluminum Machining Surface Finishes

- Aluminum Machining Tolerance

- Aluminum Machining FAQ's

- Experience: Our engineer and specialist team have extended experience and knowledge working with complex and precision CNC parts in various industry , we are able to provide you with the best solution for your project from design to production.

- Rapid Turnaround: We will respond to your inquiry within 24 hours. With our latest CNC technologies, Be-cu can finish high-precision and quick turn parts in as fast as 1-3 days, which allows us to provide our customers with reliable on-time delivery.

- Precision: We have the capability of manufacturing highly accurate CNC parts within tolerances of +/- 0.001-0.005 to achieve the high quality results.

- Custom Surface Finishes: You can select various surface finishes on solid aluminum parts from precise design specifications. We provide different surface finishes such as standard machined, smoothed, bead blasted, anodized clear or color, anodized hard-coat, power coated, electropolished, black oxide, chromate conversion coating, brushing.

- Scalability: Be-cu cnc machining is perfect for production of 1-10,000 parts. Rapid production to achieve low, medium to high volume production.

Here are the introductions to different types of metal finishes

- Galvanizing: Mainly to make the surface more beautiful and rust free.

- Chrome plating:It can make the metal products more durable. Hard chrome plating is mainly applied for machinery which under high temperature conditions, such as molds. Decorative chrome plating is mainly to make the surface brighter and more beautiful in appearance.

- Nickel plating: It is deposited on the metal surface by oxidation-reduction effect, which is used to improve corrosion resistance and wear resistance, and increase beauty and glossy.

- Titanium plating: preventing pollution, and will not cause allergic reactions in contact with the human body. Because the titanium compound has a variety of colors, it can increase the aesthetic effect. Meanwhile, titanium has the function of anti-acid, anti-alkali and anti-oxidation.

- Silver plating: There are two main functions, one is decoration and the other is functionality. Decorative silver plating are used for oxidation resistance experiments. Functionality is mainly used in the electronics industry, such as electrodes, wires, electric shocks, pole pieces, and so on.

- Gold Plating: is a method of depositing a thin layer of gold on the surface of another metal (most commonly copper or silver) through chemical or electrochemical plating.

- Passivating: In physical chemistry and engineering, it refers to coating materials to make them “passive”, that is, not susceptible to environmental influences or corrosion

- Electrophoresis painting:is a process in which metal parts are immersed in a water-based solution, and the parts are painted by passing electric current through the plating solution.

- Chromate Conversion Coating(alodine coating) :converts the surface properties of the substrate (typically aluminum or magnesium) as compared to plating which applies a coating onto the surface of the substrate

- Polishing is the finishing process of reduction of surface roughness to create a bright and smooth surface by mechanical, chemical or electrochemical action. It uses polishing tools and abrasive particles or other polishing material to enhance the visual appeal of the workpiece.

- Metal heat treatment is one of the important processes in mechanical manufacturing. By comparison with other treatment processes, heat treatment generally does not change the shape and the chemical composition of the whole workpiece, whereas it improves the performance of the workpiece by changing the internal microstructure or the surface’s chemical composition.

- Without any surface treatment processing methods, the parts will leave visible tool marks and burrs, which can be completed quickly and cost-saving.

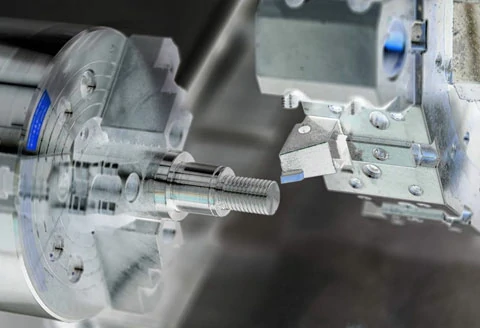

Compared to basic CNC machining services, precision aluminum machining manufacture parts to a much more exact standard. Tolerances as small as ±0.0001” with right machines.In CNC machining, our standard tolerance for aluminum is DIN-2768-1-f.

The tolerance is greatly influenced by part’s geometry and material type. For the specific tolerance details of different parts, please contact us.

| Type | Linear dimension | Hole diameters (not reamed) | Shaft diameters | Part size limit |

|---|---|---|---|---|

| Tolerance | +/- 0.025 mm; +/- 0.001 inch | +/- 0.025 mm; +/- 0.001 inch | +/- 0.025 mm ;+/- 0.001 inch | 950 * 550 * 480 mm; 37.0 * 21.5 * 18.5 inch |

Online Get a Fast Quote, On-Demand CNC Machining, Fast Production in 1-3 Days

- ISO 9001:2015 & ITAF 16949

- Advanced testing equipment

- Material certification

- First article & in-process inspections

- Final inspection before shipment

- Full dimensional report

- Rework & refund policy

CNC machining cost is mainly made of machining time, start-up cost, material cost and feature cost. In order to control cost, these factors will help you to some extent.

A design of fast machined features is the best way to reduce machining time. You could design by using correct inner radii, reducing cavity depth, increasing wall thickness, limiting thread length and choosing standard-sized holes and so forth.

Start-up cost can drop through reducing the number of part rotations or repositioning during machining. For instance, you could split the geometry into several parts to assemble them together.

Material cost reduction needs to consider the size of the required stock and both the cost and the machinability of big material. Soft alloys can be generally machined faster.

Feature cost control can consider using tolerances as necessary only, avoiding logo machining and multiple surface treatments.

For more details, please see the full guide of cost reduction about CNC machined parts.

At BE-CU, we treat your order seriously and attach great importance to the quality.

To ensure high-quality parts, any suppliers can not go into our manufacturing network except for the verified ones. We have a strict process of selecting the best suppliers as our manufacturing partners. Every partner is verified and we implement regular quality inspections on their factories every year.

Our QC carries out inspections several times from pre-production, in-production and after production to make sure of every detail of the parts within the specification. We issue a comprehensive and standardized dimensions inspection report for each order and offer a first article inspection service on bulk production.

Different certifications are available on request including but not limited to ISO9001 and ITAF 16949.

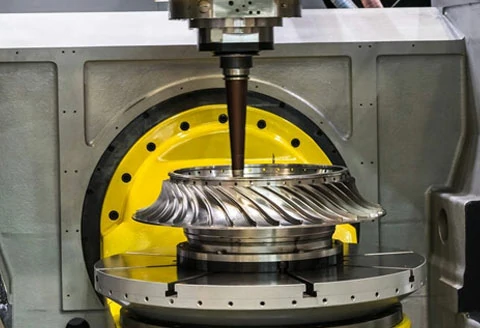

As one of the most common manufacturing processes in the world, CNC machining is widely used in various industries including aerospace, automotive, consumer electronics, robotics, agriculture and other fields where aluminum parts are frequently used. It is also applied to medical equipment, household products, energy, oil and gas, and other consumer applications.

Aluminum extrusions. Common aluminum alloy types: 6061, 6063, 6061-T5, 6063-T5. If you want to specify another aluminum alloy, please send your inquiry to us, we’ll review the feasibility and give you feedback quickly.