Before the car is overhauled into the factory, it is necessary to clean the outside of the car and the disassembled internal parts, which is stipulated in the inspection of the car entering the factory.

Before the car is overhauled into the factory, it is necessary to clean the outside of the car and the disassembled internal parts, which is stipulated in the inspection of the car entering the factory.

The purpose of cleaning the exterior of the car before disintegration is to remove the dust, mud and oil on the exterior, and at the same time, the exterior defects can be found in time, so that the defects can be repaired, so that the disassembly work can be carried out smoothly, and the disassembly site can be kept clean.

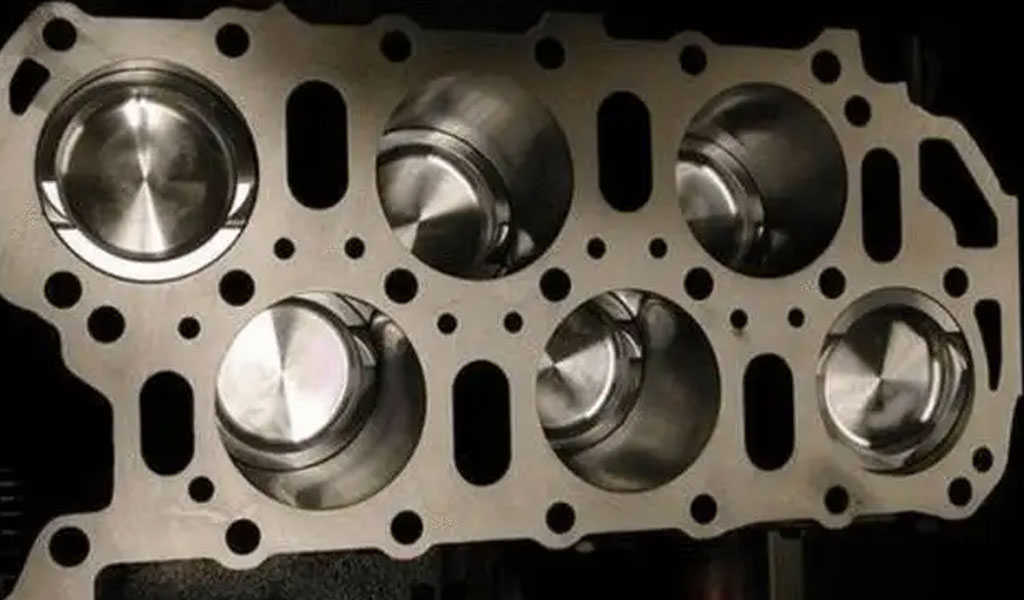

How To Clean Oxidized Aluminum Engine Parts

The oxidized engine parts is cleaned with a high-pressure water gun. The cleaning method is as follows:

- Automotive electrical appliances are covered with plastic film, and the upper side of the film is covered with a semi-wet towel to prevent high-pressure water from rushing into the dispenser;

- Use a high-pressure water gun to wash the dirt attached to the engine room and outside the engine from top to bottom from the side of the engine;

- Spray engine exterior cleaner around the wetted engine and cabin;

- Use a fiber brush to clean all accessible parts in the cabin;

- Use a high-pressure water gun to quickly clean the dirt washed away by the brush;

- Spray the engine external cleaning agent evenly around the wetted engine and cabin;

- Use a fiber brush to clean all accessible parts in the cabin;

- Use a high-pressure water gun to quickly clean the dirt washed away by the brush;

- Spray engine external cleaning agent on the engine surface;

- Dry the cleaned engine with a semi-wet towel, and use a vacuum air dryer to dry the places that are not easy to reach;

- Sand the plastic rubber parts inside the cabin with plastic rubber protectant and coat the metal parts.

The Cleaning Method Of Aluminum Car Parts – Best Cleaner For Aluminum Engine Parts

After the car is completely disassembled, the surface of the parts will inevitably have oil stains, carbon deposits, rust and scale, which must be cleaned. The method and quality of cleaning directly affect the reliability of parts, repair costs and service life after assembly.The main purpose of auto parts cleaning is to clean oil stains, remove carbon deposits, and remove scale. Common methods are:

1. Liquid Flushing Method

- The essence of the liquid flushing method is to make the cleaning liquid have a mechanical, thermal and physicochemical effect on the dirt on the surface of the parts, so that it can be separated from the surface of the parts and achieve the purpose of cleaning. Wide application range, flexible use and easy operation.

- When rinsing, when the washing liquid flows away, it will also take away the dirt from the cleaning area by the way, without causing secondary pollution. The cleaning efficiency is closely related to the properties, temperature and pressure of the cleaning solution. Generally, the decontamination effect of the washing liquid is the best. The washing temperature is within the normal range, and the stronger the impact force (ie the pressure), the higher the washing efficiency.

2. Steam Flushing Method

- The essence of the steam flushing method means that the temperature is 90~100℃ and the pressure is 0.5 A cleaning method for washing the dirt on the surface of parts with a steam flow of ~2MPa. It needs to configure a special steam device and supporting system, which requires a large investment and a high cost.

- This method is suitable for cleaning parts with serious oil pollution, but it is not easy to clean with general cleaning methods.

- The steam flushing method is a high temperature and pressure operation, and there should be suitable labor protection products, because the high temperature pressure steam splashes during flushing, if the care is not proper, it is very easy to cause injury to the operator. Due to its strong detergency and good cleaning quality, it can thoroughly clean sludge, grease, lubricating oil and its decomposition products, as well as heavily polluted surfaces such as residual coatings.

- The cleaning efficiency of this method mainly depends on the pressure and flow of the flushing liquid, and is also related to the temperature of the liquid and the activity of the cleaning agent.

3. High Pressure Flushing Method

The high-pressure washing method is a method of washing the dirt surface of the parts with hot water with a pressure of 9.8MPa. This method has a wide range of applications and can be used for complete vehicles, components and parts. Cleaning, good cleaning effect, high efficiency, easy to use. The characteristics of high pressure hot water flushing method are:

- High efficiency, low cost and no damage to the paint surface.

- The washing equipment adopts a high-pressure cleaning machine, which can provide high-pressure hot water, and the temperature of the hot water is adjustable. The temperature of the hot water in general use is about 75 ℃; when the hot water is not used for washing, it can also be washed with cold water, which has a wide range of applications. When flushing with high pressure water, there is no need for cleaning agents, thus avoiding the use of chemicals and reagents, so it does not pollute the environment.

- There are many types of equipment and materials, including various specialized water heaters, high-pressure flushing fluid pressure regulation, fluid flow regulation, automatic control and protection systems, nozzles that can obtain various forms of fluid flow, and detergent and Preservatives etc. This method can be used to complete the needs of various cleaning operations in different states, such as hot and cold water, detergent and no detergent, low pressure or high pressure. Therefore, when cleaning, the most suitable cleaning equipment and cleaning materials should be selected according to the needs of the cleaning operation.

4. Immersion Cleaning Method

The immersion cleaning method is a method in which the auto parts to be cleaned are immersed in a special container filled with cleaning liquid, and some are driven by a power device (such as ultrasonic waves) for cleaning. It is suitable for cleaning equipment and parts with complex shapes and different dirt, such as frame, cab, body, and parts with a large number of them. The characteristics of the immersion cleaning method are:

- High-efficiency alkaline synthetic detergent can be used, which has strong foaming ability and has a good effect on removing old paint and rust. Various emulsions are used to enhance the cleaning process.

- The equipment is simple in structure, easy to use and economical.

- When using this method for cleaning, if the solution is heated to 100 ℃, the best cleaning speed and cleaning quality can be improved. When this method is used for cleaning, dirt, grease, etc. will float on the surface of the solution. When removing parts, if no corresponding measures are taken, these dirts may adhere to the surface of the cleaned parts and cause secondary pollution. Therefore, Pay special attention.

- Immersion cleaning methods include: compressed air activation solution cleaning, propeller activation solution cleaning, ultrasonic cleaning and other methods.

5. Machine Cleaning Method

Machine cleaning method is to use machine tools to clean manually, this method is the simplest and easiest to do. It is suitable for all cleaning operations of the whole vehicle and parts. This is also the most widely used method in the automotive beauty industry. The characteristics of the machine cleaning method are to use common tools such as scrapers, metal brushes, and abrasive blocks to remove rust, dirt and carbon deposits on the surface of parts. Flexible operation, simple and practical. During operation, different operating tools can be selected according to the different conditions of the cleaning objects. For example: brushes made of synthetic materials can be used to remove burrs and soft rust; brushes made of mild steel can be used to remove rust from steel and cast iron surfaces; , brushes made of brass wire or bronze wire can be used. Care should be taken to use a slower speed when cleaning, so as not to damage the parts.

6. Molten Salt Cleaning Method

The molten salt cleaning method is a method of cleaning the dirt of the parts in a special molten salt or molten alkali furnace. This cleaning method is generally to put the parts to be cleaned into a specific furnace, wash them with flowing water in the furnace, then etch them in an acid solution, and finally perform secondary cleaning in hot water. This method is suitable for large-scale maintenance and beauty enterprises, mainly for the cleaning of parts. The molten salt cleaning method must have a molten salt device, which should have strong anti-corrosion properties. The cleaning process is mainly carried out in a furnace at high temperature (400℃±10℃). When the corrosion and iron oxides and other substances on the parts are removed, the parts themselves are passivated at the same time. When cleaning, the operating procedures and cleaning process should be followed, and special attention should be paid to safety protection. Because of its narrow range of use, there are many restrictions.

7. Ultrasonic Cleaning Method

The principle of ultrasonic cleaning method is to use the alternating sound pressure of ultrasonic waves to generate vibration propagation in the liquid medium, so that the liquid medium forms a dense and dense state, resulting in ultrasonic cavitation effect. When the vibration frequency and intensity of the ultrasonic wave reach a certain level, a sufficient number of cavities will be formed continuously, and then they will be closed continuously, forming an explosion force and shock wave of hundreds of megapascals at countless points, which will affect the oil contamination and accumulation on the surface of the parts. The carbon produces a peeling effect, coupled with the thermal and chemical effects of the cleaning fluid, to obtain a good cleaning effect. There are generally two types of cleaning agents for ultrasonic cleaning: water-based and non-water-based. Non-water-based cleaning agents have problems such as flammable and explosive (petroleum-based and alcohol-based), harmful to human body (chlorine-based), and high cost (fluorine-substituted); the solubility of water-based cleaning agents on oil and lipophilic dirt And the dispersing power is not enough, surfactants and appropriate alkali substances must be added to the water-based cleaning agent to improve its decontamination ability. Ultrasonic cleaning equipment is generally dedicated and can be set according to the needs of cleaning (for example, ultrasonic cleaning machine for fuel injection nozzles of EFI engines).

8. Waterless Car Washing Method

At present, a waterless car washing method is popular in the car beauty market. Its essence is to use anhydrous car washing liquid (special car washing agent) mixed with high-pressure air with a volume fraction of 98%, spray the surface of the parts with appropriate pressure, and easily remove the dirt and dirt on the surface of the parts. Cleaning method . Because there is no running water on the ground after washing the car, it is called the waterless car washing method. It is suitable for cleaning and maintenance of body paint surface, interior decoration, tires, chassis, engine and other parts. According to the survey, the waterless cleaning method can save about 98% of water; and the car washing, waxing and polishing operations can be completed at one time, with high efficiency and good economic benefits. In the cold season, if it can be equipped with a heating system, it can also meet the requirements of car washing at any time. Using the surface of the parts after anhydrous cleaning, a layer of polymer protective film is formed, which can protect the paint film, anti-static, anti-rain and snow erosion, anti-aging of the paint film, prolong the service period, and effectively cover the surface of the paint film of minor scratches. Really make the car get “beauty” purpose, and will not cause environmental pollution.

Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products