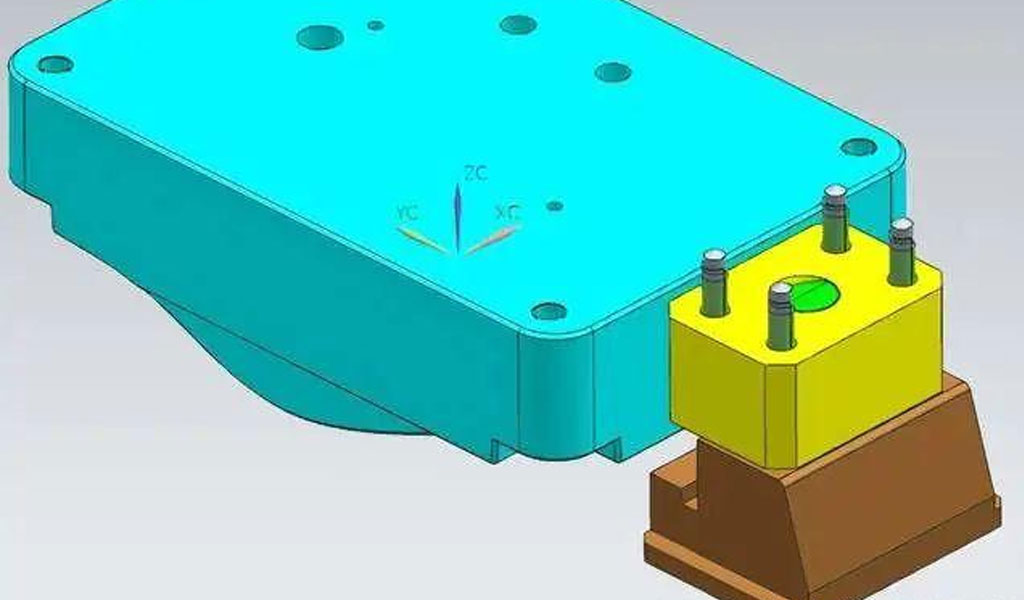

When the customer needs to remove the inclined guide post from the parting surface, when choosing the fixing method of the inclined guide post, the inclined guide post fixing block is preferred to fix the inclined guide post.  Solution: 1. Click the menu [Start]-[All Application Modules]-[Injection Mold Wizard]-[Injection Mold Tools]-[Create Block]-[Type] to select [Containing Block], use the inclined guide post cup head and the slider top face, make a 57x 40 x 27mm block as shown below:

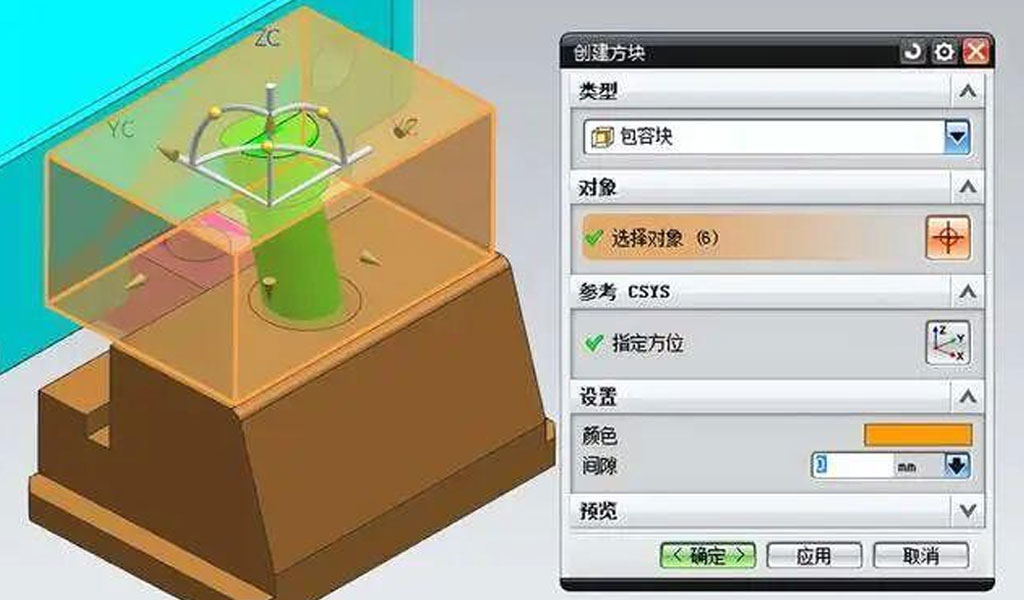

Solution: 1. Click the menu [Start]-[All Application Modules]-[Injection Mold Wizard]-[Injection Mold Tools]-[Create Block]-[Type] to select [Containing Block], use the inclined guide post cup head and the slider top face, make a 57x 40 x 27mm block as shown below:  2. Click the menu [Insert] – [Combination] – [Difference], and use the package block and the inclined guide column to find the difference, as shown in the following figure:

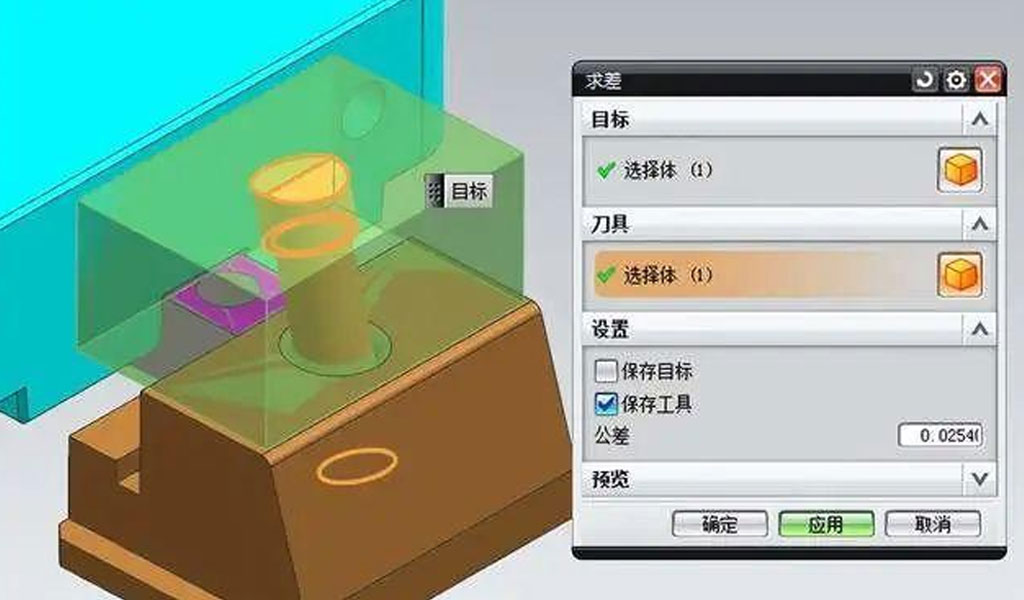

2. Click the menu [Insert] – [Combination] – [Difference], and use the package block and the inclined guide column to find the difference, as shown in the following figure:  3. Click the menu [Insert]-[Synchronous Modeling]-[Replacement Surface] to display the inclined guide post seat separately, and level the inclined guide post cup head groove of the inclined guide post base, as shown in the following figure:

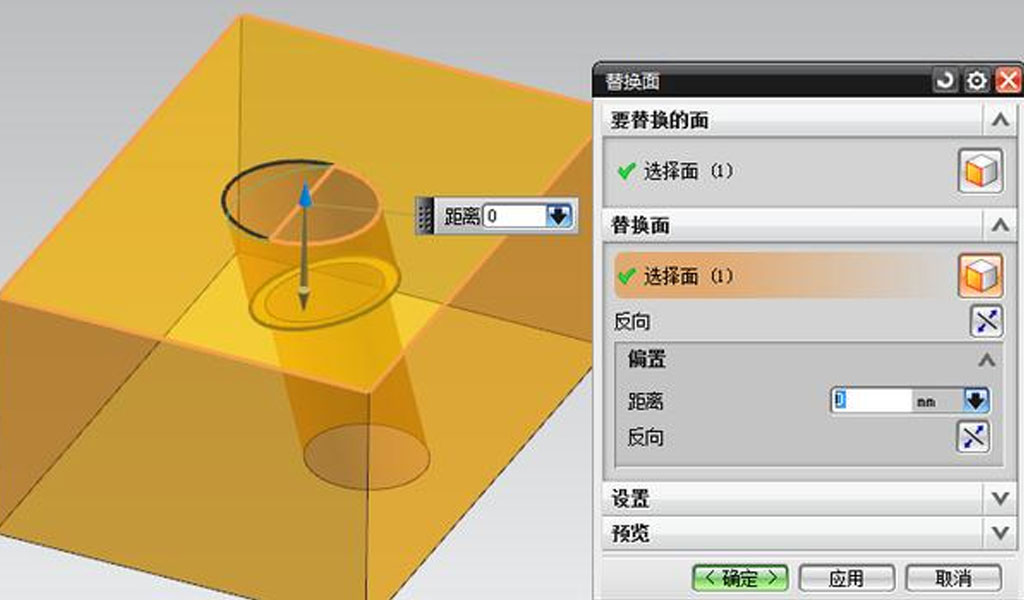

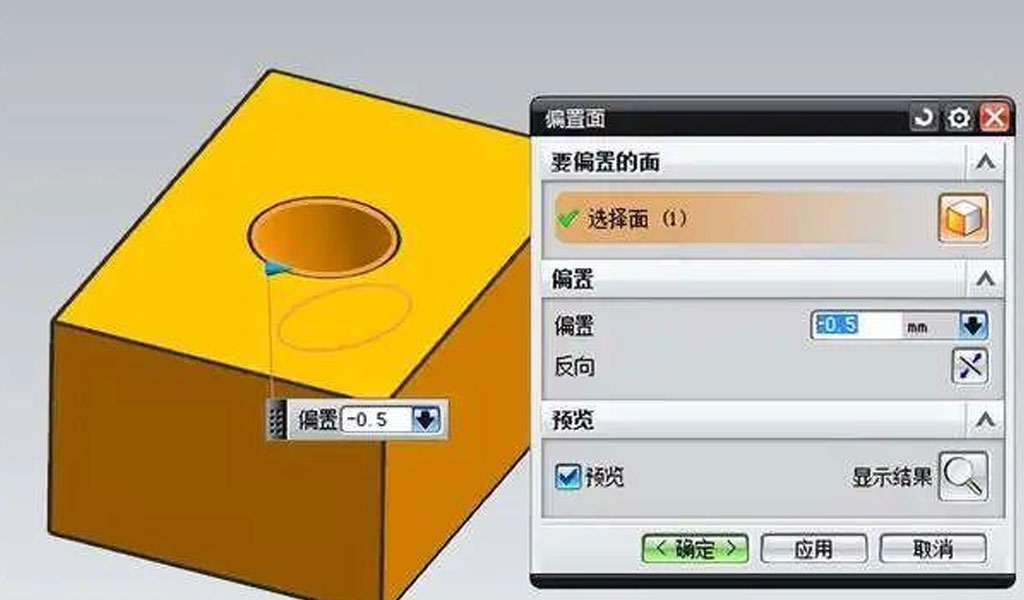

3. Click the menu [Insert]-[Synchronous Modeling]-[Replacement Surface] to display the inclined guide post seat separately, and level the inclined guide post cup head groove of the inclined guide post base, as shown in the following figure:  4. Click the menu [Insert] – [Offset] – [Offset Surface], the unilateral offset of the inclined guide column cup head groove of the inclined guide column seat is -0.5mm, as shown in the following figure:

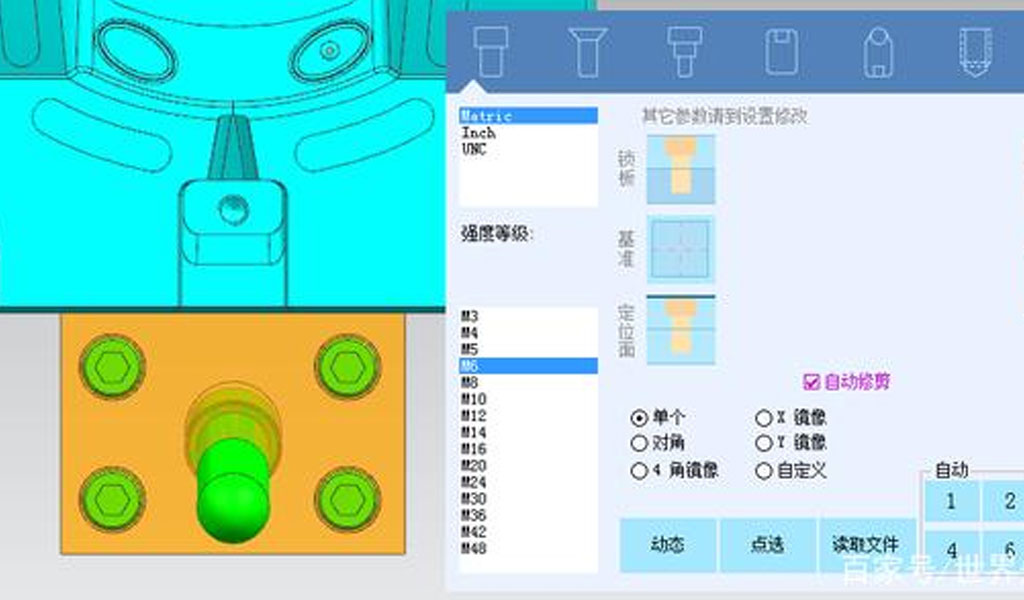

4. Click the menu [Insert] – [Offset] – [Offset Surface], the unilateral offset of the inclined guide column cup head groove of the inclined guide column seat is -0.5mm, as shown in the following figure:  5. Click on the menu [Yanxiu Mould] – [Mold Base and Related] – [Screws], show all, and design the screws for the oblique guide column seat lock A plate, as shown in the following figure:

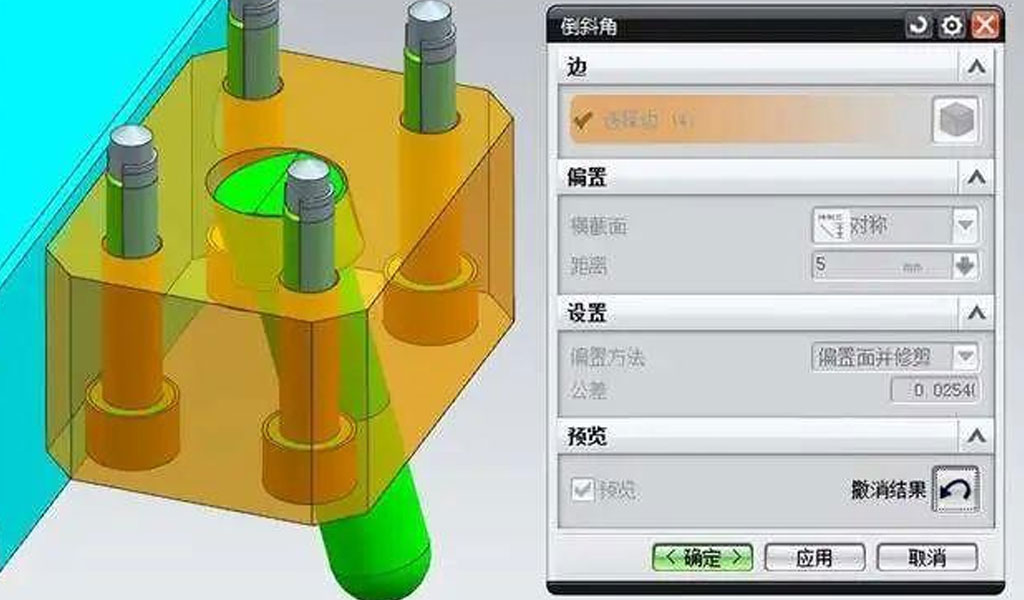

5. Click on the menu [Yanxiu Mould] – [Mold Base and Related] – [Screws], show all, and design the screws for the oblique guide column seat lock A plate, as shown in the following figure:  6. Click the menu [Insert] – [Details] – [Chamfered Angle], and design the C angle on the 4 sides of the inclined guide column. At this point, the design of the fixed block of the inclined guide column is completed, as shown in the following figure:

6. Click the menu [Insert] – [Details] – [Chamfered Angle], and design the C angle on the 4 sides of the inclined guide column. At this point, the design of the fixed block of the inclined guide column is completed, as shown in the following figure:

and design the C angle on the 4 sides of the inclined guide column. At this point, the design of the fixed block of the inclined guide column is completed,

Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products