The application of laser cutting machine has been applied to all walks of life, and is often used by some mechanical and electrical power plants, medicine and many other fields. Now let’s learn about the structure and application of common laser cutting machines: laser cutting machine equipment is mainly the integration of machine, light, electricity, and the whole system is mainly composed of: machine tool host part (mechanical part), laser (+ components of external optical path), numerical control system and console (electrical control part), together with auxiliary equipment for laser cutting: stabilized power supply, chiller, gas cylinder, air compressor, gas storage tank, Cooling dryers, filters, exhaust dust collectors, slag dischargers, etc. constitute the system integration of a complete set of equipment.

The functions of each part of the laser cutting machine are as follows:

- The main machine part of the machine tool: the machine tool part of the laser cutting machine, the mechanical part that realizes the movement of the X, Y, and Z axes, including the cutting work platform. It is used to place the workpiece to be cut, and can move correctly and accurately according to the control program, usually driven by a servo motor.

- Laser generator: a device that generates a laser light source.

- Outer light path: refraction mirror, used to guide the laser in the desired direction. In order to prevent failure of the beam path, all mirrors should be protected by protective covers, and clean positive pressure protective gas should be introduced to protect the mirrors from contamination.

- Numerical control system: It controls the machine tool to realize the movement of X, Y and Z axes, and also controls the output power of the laser.

- Regulated power supply: connected between the laser, the CNC machine tool and the power supply system. It mainly plays the role of preventing external grid interference.

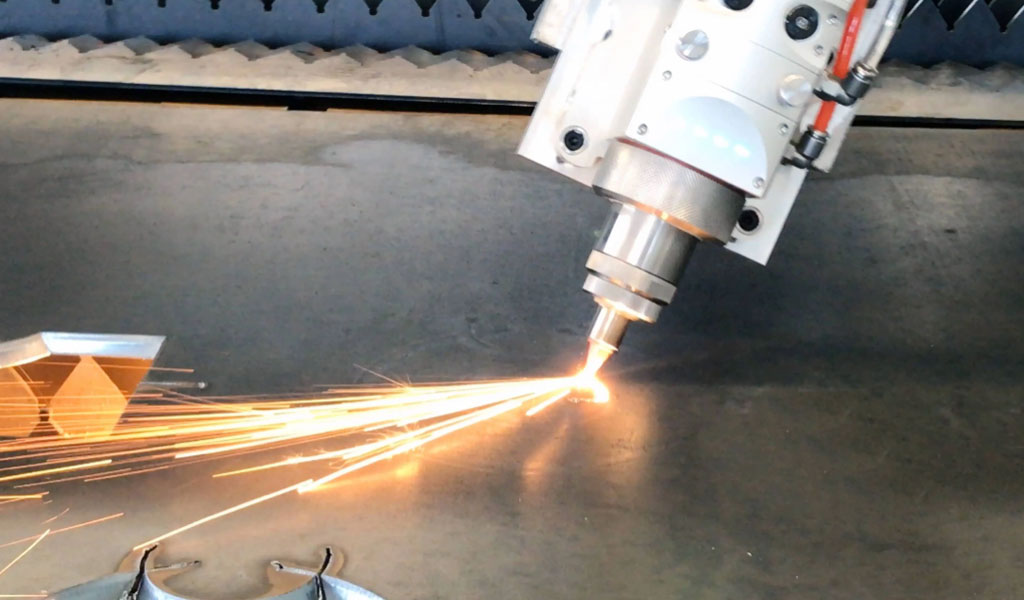

- Cutting head: It mainly includes parts such as cavity, focusing lens holder, focusing mirror, capacitive sensor and auxiliary gas nozzle. The cutting head driving device is used to drive the cutting head to move along the Z-axis according to the program, and is composed of a servo motor and transmission parts such as a screw rod or a gear.

- Operation table: used to control the working process of the entire cutting device.

- Chiller: used to cool the laser generator. Laser is a device that converts electrical energy into light energy. For example, the conversion rate of CO2 gas laser is generally 20%, and the remaining energy is converted into heat. The cooling water takes away the excess heat to keep the laser generator working properly. The chiller also cools the external optical path reflector and focusing mirror of the machine tool to ensure stable beam transmission quality and effectively prevent the lens from being deformed or burst due to excessive temperature.

- Gas cylinder: including the working medium gas cylinder and auxiliary gas cylinder of the laser cutting machine, which are used to supplement the industrial gas for laser oscillation and the auxiliary gas for supplying the cutting head.

- Air compressor, air storage tank: provide and store compressed air.

- Air cooling dryer and filter: used to supply clean dry air to the laser generator and beam path to keep the path and reflector working properly.

- Exhaust dust collector: Extract the smoke and dust generated during sheet metal fabrication, and filter it to make the exhaust gas discharge meet the environmental protection standards.

- Slag discharger: remove the leftover material and waste generated during fabrication

How To Reduce The Radiation Of Laser Cutter To Human Body

How to minimize the radiation of laser cutting machine to human body while working efficiently?

1. Necessary Laser Cutting Machine Protective Equipment

Because of the protective glasses that prevent laser damage to the human eye, the protective equipment for china laser cutting machines is typically laser protective glasses. According to its protection principle, it can be divided into reflection type, absorption type, diffraction type and compound type. Of course, the protection will be filtered according to the laser radiation wavelength of the laser cutting machine to achieve the maintenance of the laser cutting machine for the human body. The most safe and convenient protective equipment for laser cutting machines on the market.

2. Self-Protection Against Laser Cutting Machine Radiation

A little radiation of the laser cutting machine can be resisted, so the operator of the laser cutting machine should pay attention to eat more carrots, bean sprouts, tomatoes, lean meat, animal livers and other foods rich in vitamin AC and protein, if the human body has enough health level. Drink some green tea often and so on. Because these foods can help humans better maintain their eyes, so that the human body can better protect the human body under the condition of laser cutting machine radiation.

3. Dodge Yourself

If you can avoid the laser cutting machine as much as possible, this requires the attention of the laser cutting machine operator and other personnel. In other words, if you can use the CNC cutting machine to complete the work, do not use the laser cutting machine. Although the laser cutting machine is more efficient, it will cause great damage to the human body if used for a long time. Therefore, it is recommended to use the CNC cutting machine to complete the necessary work laser machine.