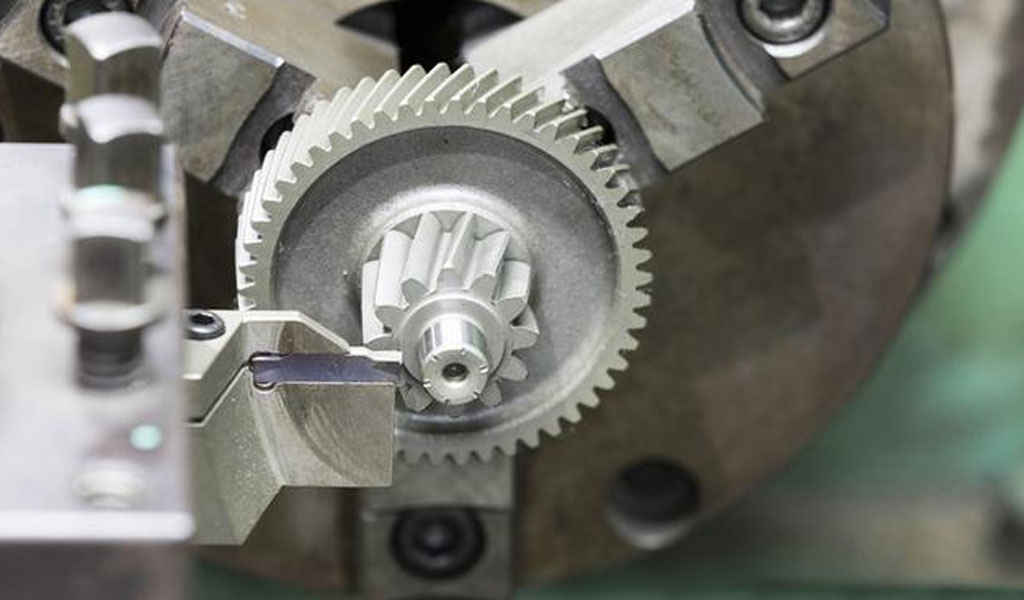

As we all know, gear transmission is the most common type of mechanical transmission in modern machines, and it is an important basic component of mechanical products. Compared with other mechanical transmission forms (chain transmission, belt transmission, hydraulic transmission, etc.), it has the characteristics of large power range, high transmission efficiency, accurate transmission and long service life. Therefore, it has become an indispensable transmission part of many mechanical products, and it is also the transmission form that accounts for the largest proportion in the machine.

The design and manufacturing level of gears will directly affect the performance and quality of mechanical products. For example, in the modern and booming automobile industry, there are usually 18 to 30 teeth in each car, and the quality of gears directly affects the noise and stability of the car. performance and service life. Gear machining technology and equipment usually greatly affect the highest manufacturing level that can be achieved in the industrial field. Advanced countries with developed modern industries such as the United States, Germany and Japan are also manufacturing powerhouses in gear machining technology and equipment. Therefore, gears have always played a prominent role in industrial development and have been recognized as a symbol of industrialization. From this point of view, it is extremely important to pay attention to the advanced machining technology and development trend of gears.

New Development Of Gear Machining Technology

Generally speaking, the gear manufacturing process includes five stages: material preparation, gear blank machining, tooth cutting, tooth surface heat treatment and tooth surface finishing. Tooth profile machining and finishing after heat treatment are the key to gear manufacturing and also reflect the level of gear manufacturing. The development of gear manufacturing process is largely reflected in the improvement of precision grade and production efficiency. At present, countries in the world are continuously improving the manufacturing level of gears mainly from the development of gear machining technology and machining equipment.

1) Hard tooth surface hobbing technology

In the traditional method, the machining of the hard tooth surface of the gear requires the grinding of the tooth surface. Because the grinding efficiency is too low, the machining cost is too high, especially for some large diameter and large module gears, it is more difficult to process. Therefore, since the 1980s, domestic and foreign companies have gradually adopted hardened tooth surface scraping as a semi-finishing and finishing method for hardened gears (40-65HRC).

The hard tooth surface hobbing technology is also called scraping tooth machining. This process uses a special carbide hob to scrape the tooth surface of the gear with a tooth surface hardness of HRC58-62 after carburizing and quenching, and the scraping accuracy can be Reach level 7. This method can process gears with any helix angle and modulus from 1 to 40mm. Ordinary precision (grade 6 to 7) hard-toothed gears generally adopt the “hobbing-heat treatment-scraping” process, and rough and finish machining can be completed on the same hobbing machine; gears with higher tooth surface roughness requirements can be scraped. Afterwards, gear honing is arranged; for high-precision gears, the “rolling-heat treatment-scraping-grinding” process is adopted, and scraping is used as a semi-finishing process instead of rough grinding, and the heat treatment deformation of the gear is removed, leaving a small and uniform allowance for machining. Fine grinding can save 1/2 to 5/6 of the grinding time, and the economic benefits are very significant. For hardened gears with large modulus, large diameter and large width, since there is no corresponding large gear grinding machine, generally only scraping can be used.

The biggest feature of hard tooth surface scraping is that the production efficiency is 5-6 times higher than that of grinding teeth. In addition, the excessive deformation of heat-treated carburizing and quenching gears can be repaired and scraped before grinding, which not only eliminates the deformation of gears It ensures the smoothness of the gear in the grinding process, improves the grinding efficiency, and protects the precision of the gear grinding equipment.

Temperature control is extremely important when machining gears with hard-tooth surface hobbing technology, because too high temperatures will speed up tool wear and cause chipping; therefore, it needs to be cooled by metalworking fluid, and at the same time, the cutting tool and workpiece are washed away. , Improve tool life and workpiece surface roughness. Generally, a special oil-based cutting fluid is used as the cooling and lubricating medium, such as KR-C20, which can meet the requirements of cooling, cleaning and lubrication in the process by properly controlling the viscosity and using an excellent environmental protection extreme pressure anti-wear agent.

2) Dry cutting technology

Dry cutting, that is, non-lubricated cutting, is one of the development trends of metal cutting. The technology began to be studied in the 1980s, but it has been developing slowly due to the constraints of machine tools and tool materials. With the development of research, dry cutting can greatly improve production efficiency and surface quality, while also reducing production costs.

High-speed dry cutting is cutting at a high cutting speed without the action of cooling and lubricating agents. Appropriate cutting conditions must be selected for high-speed dry cutting. First, use high cutting speeds to minimize the contact time between the tool and the workpiece, and then use compressed air or other similar methods to remove chips to control the temperature of the work area. Practice has proved that when the cutting parameters are set correctly, 80% of the heat generated by cutting can be taken away by the chips.

The high-speed dry cutting method not only makes the machine tool compact, but also greatly improves the machining environment and reduces the machining cost. In gear machining, in order to further prolong the life of the tool and improve the quality of the workpiece, 10-1000ml lubricating oil per hour can be used for micro-lubrication during the dry cutting process of the gear. The chips produced by this method can be considered as dry chips, and the accuracy, surface quality and internal stress of the workpiece are not negatively affected by trace amounts of lubricating oil, and automatic control equipment can also be used for process monitoring.

According to data[], the total cost of dry cutting in developed countries such as the United States, Japan and Germany is about 70% of that of traditional cutting technology. According to the statistics of American companies, in the centralized cooling machining system, the cutting fluid accounts for 14% to 16% of the total cost, while the tool cost only accounts for 2% to 4%. It is estimated that if 20% of the cutting machining is dry machining, the total manufacturing cost can be reduced by 1.6%. The advantages of dry cutting technology are also reflected in the improvement of the surface quality of the parts and the improvement of the geometric accuracy. Foreign data show that the surface roughness value of the workpiece in the dry cutting process can be reduced by about 40%. In addition, the importance of dry cutting to resources and the environment is self-evident. Germany is in a leading position in the field of high-speed dry cutting. About 8% of the enterprises currently use dry cutting, which indicates that high-speed dry gear hobbing technology will be a direction for the development of gear machining in the future.

It is foreseeable that the use of dry cutting technology in the fields of gear hobbing, gear shaping, and forming grinding will have great potential. With the advancement of gear machine tools, gear materials, gear tools, and machining technology, it is only a matter of time before the traditional technology is replaced.

3) Chipless machining of gears

Different from the traditional gear tooth forming methods such as gear hobbing, gear shaping, shaving and grinding, the chipless machining method of gears is to use plastic deformation of metal or powder sintering to finally form the toothed part of the gear or improve the quality of the tooth surface. of. The method can be divided into two categories: cold forming in which the workpiece is processed at room temperature and hot forming in which the workpiece is heated to about 1000° C. for machining. The former includes cold rolling, cold forging, etc.; the latter includes hot rolling, precision die forging, powder metallurgy, etc.

Chipless machining of gears can increase the material utilization rate from 40-50% of cutting to more than 80-95%, and the productivity can also be doubled. However, due to the limitation of the strength of the mold, currently only gears with small modules or other toothed parts can be processed. At the same time, the gears with high precision requirements still need to use cutting to finish the teeth after forming with chipless machining. shape. Chipless machining gears require special process equipment, and the initial investment is large. Only when the production batch is large (generally more than 10,000 pieces) can the production cost be significantly reduced.

Development Of Gear Machining Lubrication Technology

The development of modern cutting lubrication technology is always linked with the progress of machining equipment and machining technology. In order to adapt to new equipment and process requirements, the lubricating medium is also constantly improving.

In conventional gear machining, cutting fluids have dominated for decades. The traditional cutting lubrication process uses oil-based cutting fluid and water-based cutting fluid to lubricate and cool tools and workpieces, and play the role of chip removal and rust prevention.

In recent years, due to the increase of environmental and resource pressure, a variety of new green cutting processes have emerged in the cutting field to replace traditional machining and lubrication processes, such as non-lubricated dry cutting technology, minimal quantity lubrication technology, low temperature cold air cutting technology, etc. It promotes the progress of cutting technology, and also puts forward new requirements for machine tool structure, tool material, lubricating medium, etc.

1) Minimum quantity lubrication technology

In high-efficiency dry cutting, it is a big problem to control the spread and diffusion of heat. For this reason, technical means such as cold air (up to -100 ℃), minimal lubrication, and high-speed cutting are used in dry cutting to improve machining quality and Reduce losses.

Compared with the non-lubricated cutting technology, the minimal quantity lubrication technology introduces a cooling and lubricating medium, which greatly improves the cutting conditions and has a wider application field. Minimal Quantity Lubrication (MQL) is to mix a small amount of lubricating oil into the compressed gas to cool and lubricate the cutting point instead of a large amount of cutting fluid. MQL is an effective green manufacturing technology. The cutting fluid is supplied in the form of high-speed droplets, which increases the permeability of the lubricating medium, improves the cooling and lubrication effect, and improves the surface machining quality of the workpiece. Minimal quantity lubrication technology combines the advantages of dry and traditional wet lubrication technology, reduces the amount of cutting fluid to a very small amount, and the amount of cutting fluid used is only one ten thousandth of the amount of traditional cutting fluid, thus greatly reducing the amount of coolant It also reduces the cost of cutting fluid and reduces the burden on the human body to the greatest extent, and avoids the problem of dealing with waste fluid. Moreover, the technical system is simple, occupies a small area, and is easy to install on various types of machine tools, thus greatly enhancing the practical performance. . Therefore, many companies are committed to the development and production of minimal quantity lubrication systems, such as Germany’s Lubfix, Germany’s VOGEL, Italy’s Technosystems, and Japan’s Fuji BC Technology Research Co., Ltd. Ford Motor Company has applied minimum quantity lubrication technology to the machining of automotive powertrain parts; Grob, as an equipment manufacturer, uses a 1- or 2-channel minimum quantity lubrication system in the machining of cylinder blocks and transmissions; Guehring Company pointed out, Not only is MQL economically superior to general wet machining, but it also aids in chip handling, and the company’s adoption of MQL on solid-carbide drills has shown measurable results.

2) Low temperature and minimum quantity lubrication technology

The cooling effect of MQL is generally unsatisfactory, and the high temperature generated in the machining area causes various negative effects, such as high temperature chips affecting operator safety, workpieces and tools, etc., which are affected by temperature and reduce machining accuracy. The need for improved cooling capacity has led to the development of low temperature minimum quantity lubrication technology.

Low-temperature micro-lubrication technology[] is to mix and vaporize low-temperature compressed gas (air, nitrogen, carbon dioxide, etc.) with a very small amount of lubricating oil (10 ml/h~200 ml/h) to form micron-scale lubricating medium droplets, spraying Go to the machining area and lubricate the machining part between the tool and the workpiece. This technology integrates the characteristics of low-temperature gas cooling, medium lubrication, high-pressure injection, etc., and has excellent cooling and lubricating capabilities. It has a lot of room for development in high-speed machining of difficult-to-machine materials such as titanium alloys, high-temperature alloys and high-hardness materials. .

Gear Machining Lubricant Medium Selection

At present, oil-based cutting fluid is the main lubricating medium for gear machining, and water-based cutting fluid is also used in some rough machining fields.

Common gear machining methods include broaching, gear hobbing, gear shaping, gear shaving, gear grinding, gear honing, etc., which are suitable for different types of gear cutting. In gear machining, cutting force and cutting temperature are the main factors that cause tool wear. Therefore, using effective lubrication and cooling technology to reduce cutting temperature and improve cutting friction state, thereby reducing cutting force and suppressing tool wear, is to further improve machining efficiency. main technical approach.

In terms of selecting lubricating medium for gear machining, for oil-based cutting fluid, it is very important to choose the appropriate viscosity and lubricating performance. Generally, gear hobbing, gear shaping and other machining use higher viscosity oil, shaving, grinding and other machining. Choose oil with lower viscosity to get the best results. In addition, factors such as color, smell, oil mist, and whether it contains heavy metal elements such as barium should also be considered in the selection of products, and products that are safe for the environment and human body should be selected.

For water-based cutting fluids, it is necessary to focus on its stability, lubricity, rust resistance, biological stability and other indicators, and select the appropriate type of water-based cutting fluid according to specific machining conditions. In addition, the environmental protection and safety of the product should also be considered. The product should not contain nitrite, organic phenols, heavy metals, dioxins and other substances that are harmful to the human body, so as to ensure the health of the on-site operators.

Whether it is oil-based or water-based metal machining media, in addition to meeting the requirements of lubrication and cooling in the machining process, it also needs to meet the requirements of environmental protection and safety, so the continuous progress of technology is particularly important. Nanjing Kerun Industrial Media Co., Ltd. always adheres to the continuous innovation and progress of technology, always pays attention to the high quality of products and the importance of adapting to the human body and the environment, and strives to become the leader in green lubrication technology for gear machining.

Epilogue

Gear machining technology combines advanced achievements in material technology, machinery manufacturing, numerical control technology, simulation, lubrication technology, testing technology and many other fields. With the continuous introduction and independent development of new equipment, new processes and new technologies, the domestic gear machining industry There will be great progress.

As the only way to go in the era of industrialization, developing gear machining technology and improving the level of gear machining is of great significance to improving the competitiveness of my country’s gear manufacturing industry in the international market.