Aluminum alloy materials are widely used in medical equipment, aerospace, new energy vehicles, military industry and other industries. As its own unique advantages, such as low density, high specific strength and specific stiffness, and good corrosion resistance, it is one of the preferred processing materials for customers. Due to the wide application of aluminum alloy materials, its processing technology is becoming more and more mature, and aluminum alloy five-axis machining is one of them. For customers, aluminum alloy five-axis machining also has the following benefits:

The Benefits Of Aluminum Alloy 5 Axis Machining For Customers

- First of all, aluminum alloy five-axis machining can greatly improve machining accuracy and quality. Compared with traditional four-axis machining, five-axis machining can control the tool in multiple directions, so that the dimensional accuracy and shape and position tolerance of the processing part can be better guaranteed, especially in the processing of complex parts. Superiority.

- Secondly, aluminum alloy five-axis machining can significantly shorten the production cycle and reduce costs. The use of 5 axis machining technology can complete the machining of multiple workpieces in one clamping, which reduces the time for multiple tool changes and corrections in traditional machining, thereby improving production efficiency and shortening the production cycle. In addition, due to high processing precision and good stability, waste and defective products can be reduced in the production process, thereby reducing production costs.

- Third, aluminum 5 axis machining can improve product competitiveness and market share. Since the five-axis machining technology can guarantee the machining accuracy and quality, it can produce more precise and higher-quality products, thereby improving the competitiveness and market share of the products.

- Fourth, aluminum alloy five-axis machining can bring more benefits to customers. In addition to the benefits of the above three aspects, five-axis machining can also improve the consistency and stability of the product, enhance the durability and reliability of the product, improve the service life and safety of the product, and so on.

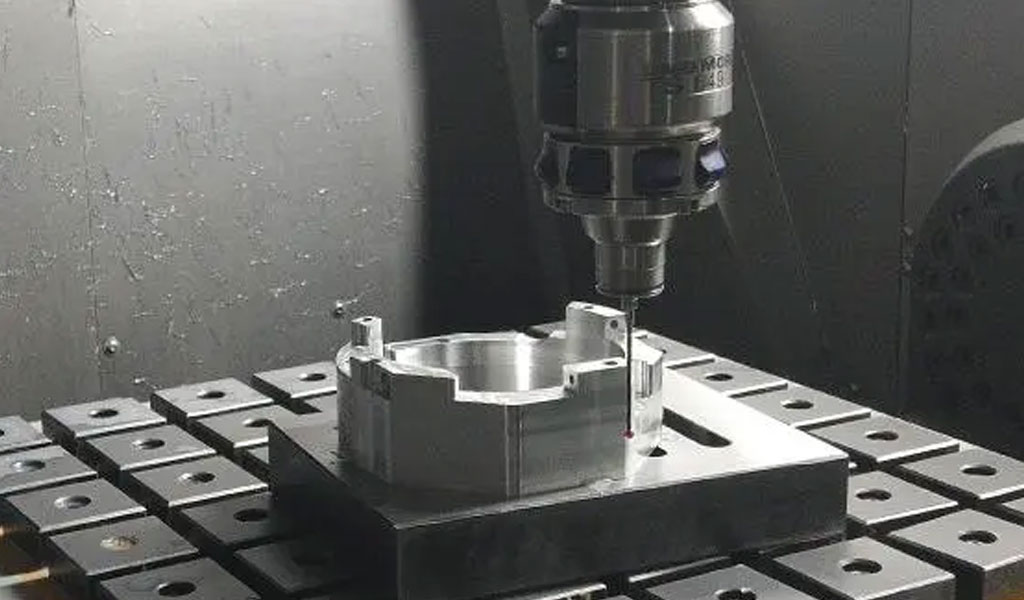

Five Axis Machining Of Aviation Aluminum Alloy

Aluminum five-axis machining technology has significant advantages in improving machining accuracy, quality, production efficiency and competitiveness. In the future development, with the continuous advancement of technology and the continuous expansion of application fields, aluminum alloy five-axis machining technology will be more widely used and developed, bringing more benefits to customers.

How To Choose Aluminum Alloy 5 Axis Machining

In the five-axis machining of aluminum alloy, due to the low strength and hardness of aluminum alloy, the cutting load is small, and the thermal conductivity is good, the heat dissipation is fast, but the melting point of aluminum alloy is relatively low, about 600°, and aluminum alloy debris is easy Sticking to the drill bit, forming built-up edge. These factors affect the machinability of five-axis machining of aluminum alloys. What should be paid attention to when using machining centers to cut aluminum alloys?

- First of all, the aluminum alloy material is soft, the spindle speed should be appropriately increased within the tolerance range of the tool, and the feed speed should be reduced as much as possible. If the feed rate is large, it will be difficult to remove chips during the entire machining process. During five-axis machining of aluminum alloy workpieces, it is imperative to adequately clamp and support the workpiece and keep the tool sharp. Otherwise, the workpiece tends to have a tendency to leave the cutting tool. If there are irregular grooves and bright extrusion spots on the machined surface, one may be caused by the abnormal pressure of the tool on the workpiece, and the other may be that when the vibration is caused by the loose clamping, the tool is on the workpiece. The surface is rubbed in gaps, extrusion and powder cutting occurs, and then when the gap or elasticity disappears, the tool bites into the surface of the workpiece, forming grooves. The aluminum alloy workpiece has higher requirements on the surface finish, so special attention should be paid during processing.

- Secondly, in order to alleviate the built-up edge produced by five-axis machining of aluminum alloy, especially to avoid the residues of built-up edge from adhering to the front surface when the built-up edge disappears, the rake face (spiral groove) of the cutting edge of the drill bit and the back tool should be The surface is polished to 0.8μm or more with oilstone, and it is best to use a drill with polished edge grooves. In order to obtain a smooth workpiece surface, the combination of drilling first and then reaming should be used as much as possible, because all kinds of qualified aluminum alloy workpiece blanks will always have some oxide layers, which will aggravate the wear of the drill bit.

- Finally, the choice of cutting fluid during five-axis machining of aluminum alloys is very important. Good lubricity, cooling, filterability and rust resistance must be guaranteed. Therefore, the cutting fluids that can be used for five-axis machining of aluminum alloys are different from ordinary cutting fluids.

During the five-axis machining of aluminum alloy, due to high-speed machining, a large amount of heat will be generated. If the heat generated cannot be taken away by the cutting fluid in time, the phenomenon of sticking to the knife will occur, and in severe cases, built-up edge will appear, which will seriously It affects the machining roughness of the workpiece and the service life of the tool. At the same time, the heat can also deform the workpiece, which seriously affects the accuracy of the workpiece. Therefore, the choice of cutting fluid should also consider the cooling performance on the basis of lubricity. For aluminum alloy finishing, you can choose low-viscosity cutting oil or semi-synthetic anti-friction cutting fluid.