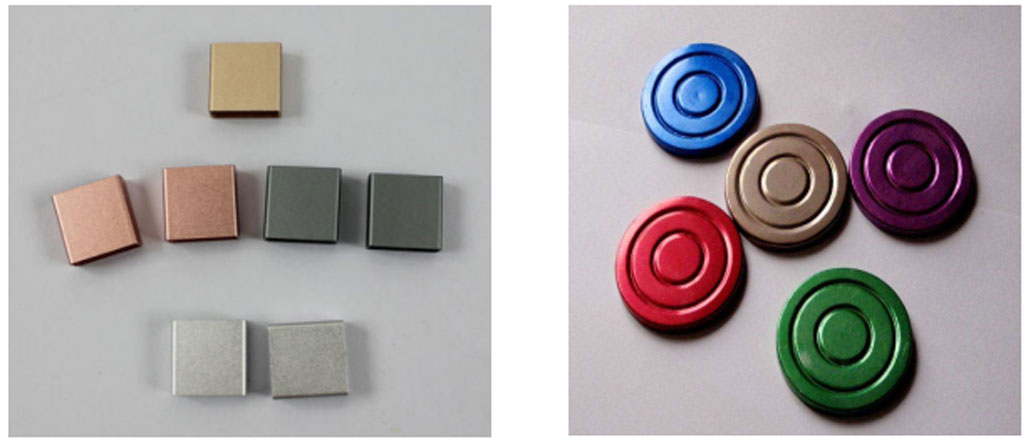

In the cnc machining process of making prototype samples, we will come into contact with various parts, which means that there are different post-processing requirements. Anodizing is one of them. Today we will introduce this process. Anodizing is a kind of electrolytic oxidation. In this process, the surface of aluminum alloy is usually transformed into an oxide film. This film has protective, decorative and other functions. It is divided into aluminum alloy hard anodizing and ordinary aluminum alloy anodized.

The Detail Of Anodizing Aluminum Cnc Prototype Parts Process

Mechanical polishing – degreasing – alkali washing – acid washing – chemical polishing – anodizing – dyeing – sealing – mechanical brightening; aluminum anodizing and dyeing processes are as follows: Pretreatment: Degreasing, Purpose: To remove oil stains on the surface of the workpiece. The method is to use carbon tetrachloride, trichloroethylene, gasoline or toluene as a cleaning agent, immerse the aluminum parts, brush them with a brush, then air dry, and then immerse them in water for multiple cleanings. Rinse with hot water immediately after the oil is gone. If a black film is formed on the surface, it should be soaked in 32% nitric acid solution for 20 seconds to remove the black film, and finally rinsed with cold water and immersed in distilled water for use as an oxide film.

- Preparation of sulfuric acid electrolyte: it is formed by mixing 18-20 kg of sulfuric acid and 80-82 kg of deionized water. At this time, the specific gravity of the solution is about 1.125-1.140. Add a small amount of oxalic acid to the electrolyte.

- Oxidation process: Install the line instrument, use the aluminum parts to be dyed as anodes and immerse them in the electrolyte, then turn on the power supply, and control according to the following process conditions

- The temperature of the electrolyte is controlled at 12-25℃, the anode current density is 1-2A/dm2, and the voltage in the tank is between 13-23V. The time is about 30-40 minutes.

After the above process is completed, take out the aluminum cnc parts from the electrolyte at any time, rinse the acid solution with clean water, and pay more attention to the low concave part, otherwise there will be white spots. After cleaning the acid solution, immerse it in clean water for use. Dyeing: After the aluminum parts are anodized, adsorption is formed on the surface, and the colored complexes are formed by covalent bonds or hydrogen bonds, and the color appears.

Dye Selection

Dyes are divided into inorganic dyes and organic dyes. Inorganic dyes are mostly composed of inorganic salts. When dyeing, the aluminum parts are soaked in two compound solutions, A and B, respectively, to generate colored compounds to achieve the purpose of dyeing.

Dyeing Operation

- Dyeing monochromatic method: Immediately immerse the aluminum products that have been anodized and washed with water in the coloring solution at 40-60℃. Soaking time: 30 seconds-3 minutes for light colors; 3-10 minutes for dark and black. After dyeing, take it out and wash with clean water.

- Multi-color dyeing method: If two or more different colors are dyed on the same aluminum part, or when landscapes, flowers and birds, figures, and characters are printed, the procedures are very complicated, such as paint masking method, direct printing and dyeing method, foam plastic Dyeing method, etc. The above methods operate differently, but the principles are the same. Now the paint masking method is introduced as follows: This method is mainly to apply the quick-drying and easy-to-clean varnish thinly and evenly on the really needed yellow to mask it. After the paint film is dry, immerse all the aluminum parts in dilute chromic acid solution to remove the yellow color of the unpainted part, take it out, wash off the acid solution with clean water, dry it at low temperature, and then dye it red. , Four colors can be operated according to the above method.

Sealing: After the dyed aluminum parts are washed with water, they are immediately put into distilled water at 90-100°C and boiled for 30 minutes. After such treatment, the surface becomes uniform and non-porous, forming a dense oxide film. The dyes coated for coloring are deposited in the oxide film and can no longer be wiped off. The sealed oxide film no longer has adsorption properties, and the wear resistance, temperature resistance and insulation properties are enhanced. Dry the surface of the sealed aluminum parts, and then polish them with a soft cloth, you can get beautiful and bright aluminum products, such as dyeing multi-color, after the sealing treatment, the protective agent applied on the aluminum parts should be removed. The area is wiped off with cotton dipped in acetone. For large areas, the dyed aluminum parts can be dipped in acetone to wash off the paint. Common processes for anodizing aluminum alloys are: sulfuric acid anodizing process, chromic acid anodizing process, oxalic acid anodizing process and phosphoric acid anodizing process. The most commonly used is sulfuric acid anodizing.

Sulfuric acid anodic oxidation: At present, the widely used anodic oxidation process at home and abroad is sulfuric acid anodic oxidation. Compared with other methods, it has great advantages in production cost, oxide film characteristics and performance. It has low cost, good film transparency, It has the advantages of good corrosion resistance and friction resistance, and easy coloring. It uses dilute sulfuric acid as the solution to anodize the product, the thickness of the film can reach 5um—20um, the film has good adsorption, colorless and transparent, simple process and convenient operation.

Chromic acid anodizing: The film obtained by chromic acid anodizing is relatively thin, only 2–5um, which can maintain the original precision and surface roughness of the workpiece: low porosity, difficult to dye, and can be used without sealing; the film is soft , The wear resistance is poor but the elasticity is good; the corrosion resistance is strong, and the chromium has a small dissolving degree of the aluminum soluble jade mesh, so that the residual liquid in the pinhole and crevice has less corrosion to the parts, and is suitable for castings and other structural parts. Used more in the military. At the same time, the quality of the components can be inspected, and the brown electrolyte will flow out at the crack, which is obvious.

Oxalic acid anodization: Oxalic acid has low solubility for aluminum oxide film, so the oxide film has low porosity, and the film wear resistance and electrical insulation are better than those of sulfuric acid film; but the cost of oxalic acid oxidation is 3~5 times higher than that of sulfuric acid; Both the cathode and the anode will be reacted, resulting in poor stability of the electrolyte; the color of the oxalic acid oxide film is easy to change with the process conditions, resulting in a color difference in the product, so the application of this process is limited to a certain extent. However, it is more common to use oxalic acid as a sulfuric acid oxidation additive. Phosphoric acid anodic oxidation: The oxide film dissolves more in phosphoric acid electrolyte than sulfuric acid, so the oxide film is thin (only 3um) and the pore size is large. Because the phosphoric acid film has strong water resistance, it can prevent the adhesive from aging due to hydration, so that the bonding force of the adhesive is better, so it is mainly used for the surface treatment of printed metal plates and the pretreatment of aluminum workpiece bonding.

Anodizing: Overcome the defects of aluminum alloy surface hardness, wear resistance, etc., expand the scope of application, prolong the service life, improve corrosion resistance, enhance wear resistance and hardness, and protect the metal surface. Compared with ordinary oxide film, aluminum alloy hard anodizing has the following characteristics: Thicker oxide film (generally not less than 25um), higher hardness (greater than 350HV), better wear resistance, lower porosity, and breakdown resistance The voltage is higher and the surface flatness may appear slightly worse.

Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products