The Characteristics Of Aluminum Substrate

- Surface mount technology (SMT) is adopted;

- Very effective treatment of heat diffusion in circuit design;

- Reduce the operating temperature of the product, improve the power density and reliability of the product, and prolong the service life of the product;

- Reduce product volume and reduce hardware and assembly costs;

- Replace the fragile ceramic substrate to obtain better mechanical durability.

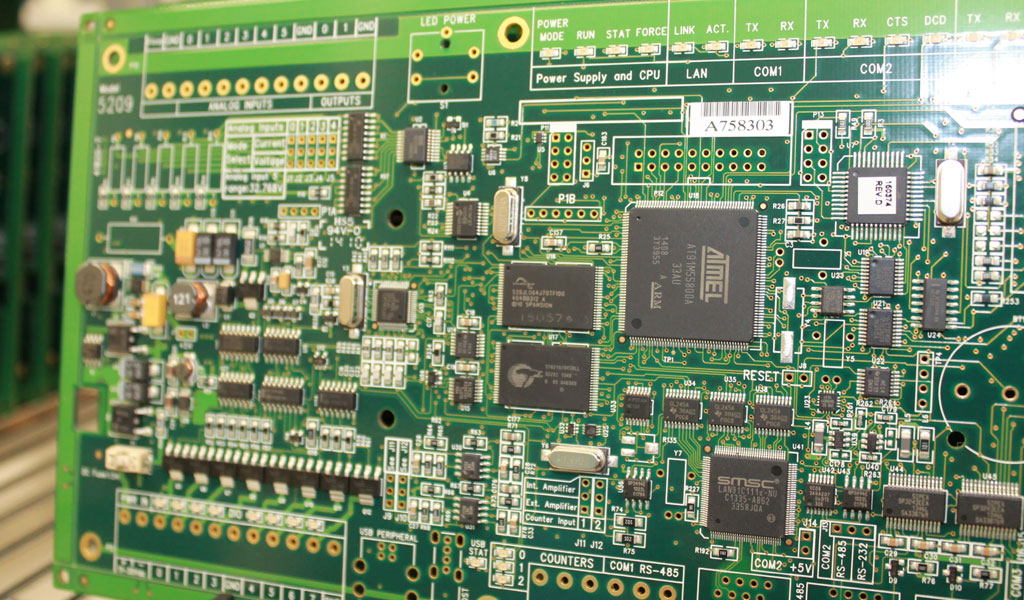

The Structure Of PCB Aluminum Substrate

PCB aluminum based copper clad laminate is a kind of metal circuit board material, which is composed of copper foil, thermal insulation layer and metal substrate. Its structure is divided into three layers:

- Cireuitl. Layer circuit layer: copper clad laminate equivalent to ordinary PCB, and the thickness of circuit copper foil is LOZ to 10oz.

- Dielcctric layer: the insulating layer is a layer of low thermal resistance and heat conduction insulating material. Thickness: 0.003 “to 0.006” inch, which is the core technology of aluminum based copper clad laminate and has obtained UL certification.

- Base layer: it is a metal substrate, generally aluminum or optional copper. Aluminum based copper clad laminate and traditional epoxy glass cloth laminate.

The Application Of PCB Aluminum Substrate

- Audio equipment: input and output amplifiers, balance amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

- Power supply equipment: switch regulator ` DC / AC converter ` SW regulator, etc.

- Communication electronic equipment: high frequency amplifier ` filter electric appliance ` transmitting circuit.

- Office automation equipment: motor driver, etc.

- Automobile: electronic regulator, igniter, power controller, etc.

- Computer: CPU board, floppy disk drive, power supply device, etc.

- Power module: converter, solid relay, rectifier bridge, etc.

- Lamp decoration: with the promotion of energy-saving lamps, the aluminum substrate applied to LED lamps has also begun to be applied on a large scale.

Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products