With the repetition of the global epidemic, we must pay attention to the processing of mask machine parts. When processing parts, cracks will appear in the parts. The source of the cracks is brought by the abrasive tools in the R&D and design process. No material can be completely without drawbacks. , but the quantity and degree are different. Although we have made efforts in technical operation and other aspects, there are still more disadvantages than metal materials. Also, this does not mean that products with shortcomings will inevitably cause cracks, mainly The thing is that the product is not easy to plastically deform like a metal under the action of foreign objects, and it is easier to concentrate the stress on a small part, which can quickly convert these shortcomings-crack sources into cracks. The critical size of the crack, the internal stress immediately concentrates on the crack tip and expands to the side of the tip. It cannot absorb the energy brought by foreign objects by changing its shape exactly like metal, it can only absorb the energy in the form of a new surface. A kind of energy, the expansion of cracks means the formation of two new surfaces, and the senior experts in mask machine parts processing tell you that the cracks expand rapidly.

It is worth mentioning that the surface polishing operation of the mask machine parts processing mold is not only affected by the technological process and polishing equipment, but also affected by it. As for the influence of the mirroring degree of the part data, some of these are not affected in the current processing. It has not received sufficient attention. It is also recommended that polishing itself is also affected by data. Although the processing technology to improve the surface performance of mask machine parts is constantly improving, the commonly used processing technology of mask machine parts is fundamentally the accumulation of hardened film, seepage Nitrogen and carburizing, some parts will be severely rubbed, deformed and scrapped unpreventably, and replaced by new parts, these parts are called accessories or spare parts, accessories or spare parts can not be repaired or selected for operation, which is called Interchangeability, in order to achieve interchangeability, when producing parts, the size and geometry of the parts should be consistent, the so-called consistency does not mean that it is not economical or difficult to achieve completely (neither economical nor impossible), Only keep the size and geometry of the part within the allowable range.

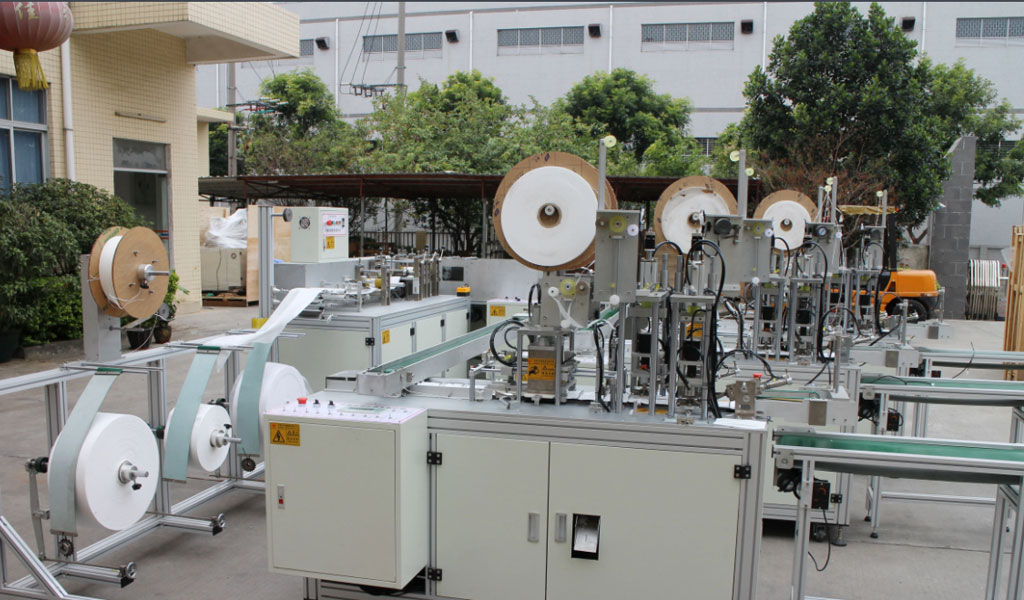

Production steps of masks:

With the repetition of the global epidemic, we must pay attention to the processing of mask machine parts. When processing parts, cracks will appear in the parts. The source of the cracks is brought by the abrasive tools in the R&D and design process. No material can be completely without drawbacks. , but the quantity and degree are different. Although we have made efforts in technical operation and other aspects, there are still more disadvantages than metal materials. Also, this does not mean that products with shortcomings will inevitably cause cracks, mainly The thing is that the product is not easy to plastically deform like a metal under the action of foreign objects, and it is easier to concentrate the stress on a small part, which can quickly convert these shortcomings-crack sources into cracks. The critical size of the crack, the internal stress immediately concentrates on the crack tip and expands to the side of the tip. It cannot absorb the energy brought by foreign objects by changing its shape exactly like metal, it can only absorb the energy in the form of a new surface. A kind of energy, the expansion of cracks means the formation of two new surfaces, and the senior experts in mask machine parts processing tell you that the cracks expand rapidly.

It is worth mentioning that the surface polishing operation of the mask machine parts processing mold is not only affected by the technological process and polishing equipment, but also affected by it. As for the influence of the mirroring degree of the part data, some of these are not affected in the current processing. It has not received sufficient attention. It is also recommended that polishing itself is also affected by data. Although the processing technology to improve the surface performance of mask machine parts is constantly improving, the commonly used processing technology of mask machine parts is fundamentally the accumulation of hardened film, seepage Nitrogen and carburizing, some parts will be severely rubbed, deformed and scrapped unpreventably, and replaced by new parts, these parts are called accessories or spare parts, accessories or spare parts can not be repaired or selected for operation, which is called Interchangeability, in order to achieve interchangeability, when producing parts, the size and geometry of the parts should be consistent, the so-called consistency does not mean that it is not economical or difficult to achieve completely (neither economical nor impossible), Only keep the size and geometry of the part within the allowable range.

Production steps of masks:

- 1. The inner layer mask is formed, and the shape of the mask is formed by hot pressing of the shaping cotton;

- 2. The outer face mask is formed, and the sheet mask can be made of non-woven fabrics, melt-blown fabrics, activated carbon non-woven fabrics and other materials;

- 3. Multi-mask pressing, pressing the inner and outer masks, usually three to five layers of masks are formed;

- 4. Trim the edges, cut the excess edges of the pressed mask, and leave the complete mask shape;

- 5. The nose line is fitted, and the mask uses the nose line to adjust the wearing position, and can use aluminum strips, rubber strips and other fixed materials;

- 6. Ear strap welding, welding the ear straps to both ends of the mask, there are many kinds of ear strap materials, you can weld 1 to 2 pieces;

- 7. Mask processing, packaging, disinfection and other steps

What are the reasons for the insufficient output energy of the mask machine equipment

The reason for the insufficient output energy of the mask machine equipment When encountering such a situation where a small machine is used as a large object, the usual methods are divided into several welding, increasing the ultrasonic output power (increasing the segment), or increasing the welding time and pressure. However, this also produces the phenomenon of unstable quality, because the voltage and air pressure directly affect the stability of the ultrasonic output power. That is to say, during work or peak hours, the quality of products using ultrasound is different from the stable quality after everyone gets off work. The reason why the output energy of the mask equipment is insufficient is that when a small machine is used as a large object, the usual methods are divided into several welding, increasing the ultrasonic output power (increasing the segment), or increasing the welding time and pressure. However, this also produces the phenomenon of unstable quality, because the voltage and air pressure directly affect the stability of the ultrasonic output power. That is to say, during work or peak hours, the quality of products using ultrasound is different from the stable quality after everyone gets off work.

How to reduce the failure rate of automatic mask machine?

The ultrasonic automatic mask making machine is an advanced mechanical control system. It can control the material through PLC programming and complete the machine at one time. In the overall production process, the operation can be completed only by feeding the material. This is an automatic production method. How to automate The combination with mechanization has become the focus. The ultrasonic automatic mask machine can operate all the work by one person, which greatly improves the production efficiency.

If the mask machine has a performance failure due to long-term operation, relevant staff can be invited to repair it. On the one hand, it can maintain the machinery and prolong its life, and on the other hand, protect the mechanical parts from damage, so the maintenance and maintenance of the automatic mask machine, Many production failures can be reduced.

When the relevant production personnel operate the mask machine, it is inevitable to shut down the ultrasonic automatic mask machine during off-duty hours, and conduct a comprehensive inspection and cleaning of the machinery. The sundries and garbage on the mask machine can be cleaned with alcohol and detergent, and can be checked at the same time. Whether the mask machine has errors and wear, the lines of the mask machine can be checked, and the components, electrical boxes and other equipment can be regularly maintained.

The ultrasonic automatic mask making machine is an advanced mechanical control system. It can control the material through PLC programming and complete the machine at one time. In the overall production process, the operation can be completed only by feeding the material. This is an automatic production method. How to automate The combination with mechanization has become the focus. The ultrasonic automatic mask machine can operate all the work by one person, which greatly improves the production efficiency.

If the mask machine has a performance failure due to long-term operation, relevant staff can be invited to repair it. On the one hand, it can maintain the machinery and prolong its life, and on the other hand, protect the mechanical parts from damage, so the maintenance and maintenance of the automatic mask machine, Many production failures can be reduced.

When the relevant production personnel operate the mask machine, it is inevitable to shut down the ultrasonic automatic mask machine during off-duty hours, and conduct a comprehensive inspection and cleaning of the machinery. The sundries and garbage on the mask machine can be cleaned with alcohol and detergent, and can be checked at the same time. Whether the mask machine has errors and wear, the lines of the mask machine can be checked, and the components, electrical boxes and other equipment can be regularly maintained.Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products