With the development of modern industry, the application of light metal materials is becoming more and more extensive. Aluminum and aluminum alloys have a series of advantages such as low density, strong electrical and thermal conductivity, excellent mechanical properties, and good machinability, and have been widely used in various sectors of the national economy. In the field of construction, for example, 98% of high-rise buildings in Japan use aluminum alloys for doors, windows and wall decoration. Compared with ordinary wooden doors and windows and steel doors and windows, aluminum alloy doors and windows have the characteristics of light weight, material saving, beautiful appearance, corrosion resistance, and convenient maintenance.

Although the cost is 3-4 times higher than ordinary wooden doors and windows, due to the low long-term maintenance cost, so Has broad prospects for development. In the atmosphere, the surface of aluminum and aluminum alloy can form an oxide film when it interacts with oxygen, but the film is thin (3×10-3~5×10-3μm) and loose and porous, which is amorphous, non-uniform and discontinuous. film, not a reliable protective-decorative film. At present, anodizing or chemical oxidation of aluminum is widely used in industry to form an oxide film on the surface of aluminum and aluminum alloy parts to achieve the purpose of protection and decoration.

The thickness of the oxide film obtained by chemical color oxidation treatment is generally 0.3~4μm, and its softness, wear resistance and corrosion resistance are lower than that of the anodic oxide film. The thickness of the oxide film obtained by anodizing treatment is generally 5~20μm, and the thickness of the hard anodized film can reach 60~250μm. The film layer is firmly bonded to the base metal, and has high corrosion resistance, wear resistance and hardness. The porous oxide film has a strong adsorption capacity, is easy to be colored with organic dyes, and also has the characteristics of good insulation performance, strong thermal insulation and heat resistance. To sum up, the editor believes that after aluminum and aluminum alloys are anodized, the oxide film formed on the surface has good protection-decoration and other characteristics. Therefore, it is widely used in aviation, electrical appliances, electronics, machinery manufacturing and light industry. The hardness of pure aluminum oxide film is higher than that of aluminum alloy oxide film. Usually, its hardness is related to the alloy composition of aluminum and the technical conditions of the electrolyte during anodization.

The anodized film not only has high hardness, but also has good wear resistance. In particular, the porous oxide film on the surface layer has the ability to adsorb lubricants, which can further improve the wear resistance of the surface. This is due to the high chemical stability of the anodic oxide film. After testing, the anodic oxide film of pure aluminum has better corrosion resistance than the anodic oxide film of aluminum alloy. This is because the inclusion of alloy components or the formation of metal compounds cannot be oxidized or dissolved, so that the sandblasted oxide film is discontinuous or voids are generated, thereby greatly reducing the corrosion resistance of the oxide film. Therefore, the film obtained after anodic oxidation must be sealed to improve its corrosion resistance.

The anodic oxide film of aluminum and aluminum alloys has a porous structure with strong adsorption capacity, so filling the pores with various pigments, lubricants, resins, etc. can further improve the protection, insulation, wear resistance and decorative properties of aluminum products. This is because the thermal conductivity of the anodized film is much lower than that of pure aluminum, and the anodized film can withstand temperatures around 1500°C, while pure aluminum can only withstand 660°C.

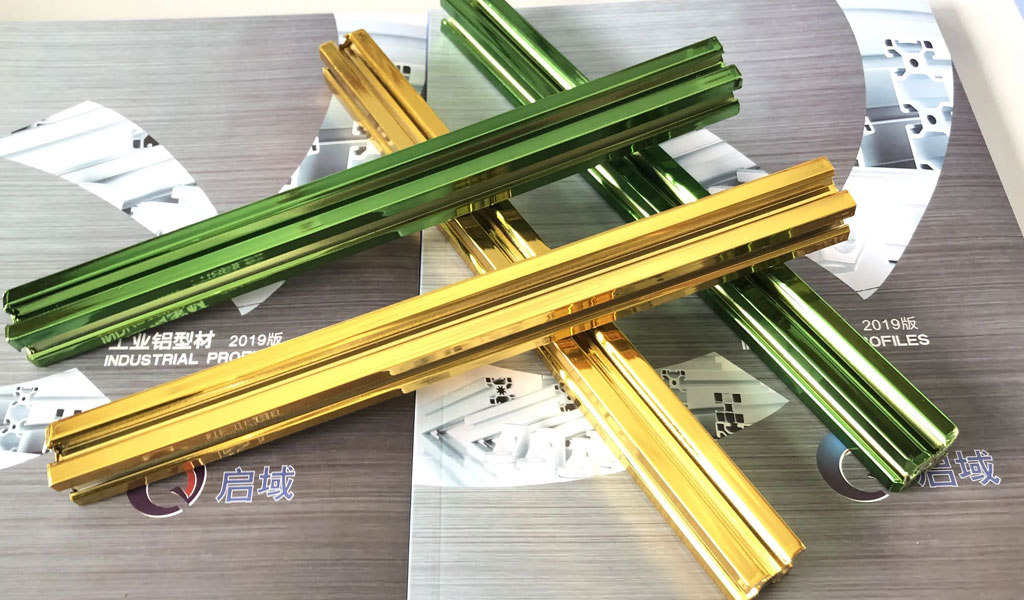

Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products