Aluminum 2024 and Aluminum 7075 are two of the most commonly used aluminum alloys in aerospace, automotive, and structural applications. Both alloys are valued for their high strength-to-weight ratios, corrosion resistance, and machinability, but they differ significantly in their chemical composition, mechanical properties, and applications. Chemical Composition Aluminum 2024 is primarily an aluminum-copper alloy. It contains approximately 3.8-4.9% copper, 0.3-0.9% manganese, 1.2-1.8% magnesium, and small amounts of other elements such as iron and silicon. The high copper content gives 2024 aluminum its excellent strength but also makes it more susceptible to corrosion compared to other aluminum alloys. Aluminum 7075, on the other hand, is an aluminum-zinc alloy with significant amounts Read more

Generally, the metal 3D printing technology based on powder forming often has high requirements on the material and physical and chemical properties of its basic unit, the metal powder. Take the selective laser melting 3D printing technology as an example: on the one hand, due to the use of laser melting metal, it is difficult to form high reflectivity and non-weldable alloy materials; on the other hand, the use of powder tank powder supply technology requires high fluidity of metal powder, and generally coarser (particle size range 15-53 μm) spherical metal particles are used as forming materials for printing. The preparation process of spherical metal powder further increases the cost Read more

1. I have a question In mechanical design, we often use aluminum alloys. For example, 6061-T6 and 7075-T651 are the two most used aluminum alloys. Because they have a good weight-to-strength ratio, that is to say, they are light in weight and good in strength, so they are very popular, especially for weight-sensitive places, such as high-speed sports platforms, aircraft structures, bicycle racks, etc. So here comes the question, what is the difference between 6061-T6 and 7075-T651? What is the meaning of 6xxx and 7xxx? T6 VS T651? Having said that, I have to talk about the classification and naming of aluminum alloys. 2. Classification of aluminum alloy (1) Forged Read more

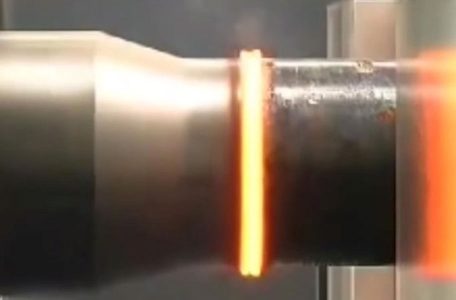

The Define Of Friction Welding Process What is friction welding? Friction welding refers to a method of welding by using the heat generated by the friction of the contact surface of the workpiece as a heat source to cause the workpiece to plastically deform under the action of pressure. Under the action of pressure, under the action of constant or increasing pressure and torque, the relative motion between the welding contact end surfaces is used to generate frictional heat and plastic deformation heat in the friction surface and its surrounding area, so that the temperature of the surrounding area rises to In the temperature range close to but generally lower Read more

CaO, MgO, SiO2 and transition metal and rare earth metal oxides are commonly used as additives in 95 porcelain. It can be fired at a lower temperature, and there are generally 10% (volume) glass phase and subcrystalline phase in the microstructure. In the CaO-AI2O3_ _SiO2 system phase diagram, the lowest eutectic phase temperature is 1495 ° C. When the ratio of SiO2/CaO in the porcelain composition is <2.16, the minerals that coexist with corundum are anorthite and calcium hexaaluminate; and when SiO2/CaO>2.16, corundum will coexist with mullite and anorthite. The advantages of the MgO-AI2O3-SiO2 system are good acid resistance and fine grains in the structure, but the sintering temperature is Read more

The melting point of aluminum is 660° Celsius. Aluminum is an active metal, and a dense oxide film about 50 angstroms thick is immediately formed on the surface of aluminum in dry air, so that aluminum will not be further oxidized and can be resistant to water; but aluminum powder is easily combustible when mixed with air; molten aluminum can be mixed with Water reacts violently; aluminum is amphoteric, easily soluble in strong bases, and also soluble in dilute acids. The characteristics of aluminum are as follows: Aluminum is a silver-white light metal, relatively soft, with a density of 2.7 grams per cubic centimeter, a melting point of 660.4 degrees, Read more

Aluminum alloys can be divided into two categories: cast aluminum alloys and deformed aluminum alloys according to their composition and process properties. Deformed aluminum alloys are divided into four categories according to their performance and process performance: rust-proof aluminum, hard aluminum, super-hard aluminum and forged aluminum. 1. Anti-Rust Aluminum The main alloying elements of rust-proof aluminum are manganese and magnesium, which belong to Al-Mn and Al-Mg system alloys. This kind of aluminum alloy belongs to the aluminum alloy that cannot be strengthened in time. After forging and annealing, it is a single-phase solid solution with high corrosion resistance and good plasticity. Manganese can improve the strength of aluminum alloy in Read more

As a light alloy with high strength and toughness, good corrosion resistance, good workability and welding performance, aluminum alloy is widely used in the aerospace field. Due to its excellent comprehensive performance, it has become the skin and frame of aircraft and the main structure of spacecraft. The preferred material [1-3], the main role is to bear and transmit loads [4]. At present, most aircraft in our country have the phenomenon of “flying less and parking more”. Among them, more than 95% of the calendar life of military aircraft is parked on the ground, and the ground corrosion effect is much higher than that of air fatigue, which is the Read more

Aluminum nitride ceramics have excellent thermal, mechanical and electrical properties, such as: high thermal conductivity (theoretical value is 320W/(m K)), low dielectric constant (about 8 at 1MHz), and silicon (Si) phase. Matching linear expansion coefficient (293 ~ 773K, 4.8 × 10-6K-1), excellent electrical insulation (volume resistivity greater than 1012Ω·m), low density (3.26g/cm3), non-toxic, high specific strength Therefore, aluminum nitride ceramics have a wide range of applications in power electronic devices, automotive industry, electric vacuum devices and other fields. Main methods of metallization of aluminum nitride ceramics To use aluminum nitride ceramics as electronic devices, it is often necessary to effectively connect with other materials (metals, alloys, etc.). In order to Read more

As an important lightweight material, aluminum honeycomb panels are widely used in the aviation manufacturing industry, and have long been used in foreign railway vehicles. They are widely used, such as the French TGV series and the Italian ETR series high-speed trains. In China, aluminum honeycomb panels have only been used in recent years. Although they have achieved certain results, their application scope is still very limited. The understanding of the characteristics and application scope of honeycomb sandwich materials needs to be further strengthened and expanded. Aluminum honeycomb panel is a composite material formed by bonding aluminum honeycomb core material and surface material. In general, aluminum honeycomb panel has the Read more