In our daily life, we often see widely used aluminum profile housings and aluminum die casting housings. Compared with aluminum die-casting housings, aluminum profile housings have their own advantages. Aluminum profile housings are various housings made of aluminum alloys. Convenience, high flexibility, high grade, can effectively increase the added value of products, and can be widely used in the electronics industry, generally including aluminum profile shells and aluminum die-casting shells. So what is the difference between aluminum profile shell and aluminum die-casting shell? Next, BE-CU.COM author will introduce it.

In our daily life, we often see widely used aluminum profile housings and aluminum die casting housings. Compared with aluminum die-casting housings, aluminum profile housings have their own advantages. Aluminum profile housings are various housings made of aluminum alloys. Convenience, high flexibility, high grade, can effectively increase the added value of products, and can be widely used in the electronics industry, generally including aluminum profile shells and aluminum die-casting shells. So what is the difference between aluminum profile shell and aluminum die-casting shell? Next, BE-CU.COM author will introduce it.

Aluminum Profile Shell

The aluminum profile shell is a shell processed on the aluminum profile obtained by aluminum drawing. It has high flexibility and can be cut at any depth. Generally, there is a circuit board slot inside. Just insert the circuit board directly, no need to do it again. Fixation and convenience are unmatched by other types of shells, but the aluminum profile shells generally have poor waterproofness and are not suitable for use in the wild and harsh environments. Scope of application: car computer, power amplifier, receiver, instrumentation, radio frequency, laser light, inverter, rectifier, electronic components, shielding box, controller, transmitter, amp, PCB circuit board, radio, GPS, mobile power supply , communications, etc. Process characteristics of aluminum profile molds: aluminum profiles are very complex, especially ultra-high-precision thin-walled hollow profiles and porous hollow-walled profiles, which require a special mold structure. The thickness of the section changes sharply, the related dimensions are complex, and there are many arc corners, which brings a lot of trouble to the processing and heat treatment of the mold. The processing technology of the extrusion die is different from the general mechanical manufacturing process, but a special technology with great difficulty and a wide range of coverage. Have a reasonable processing technology

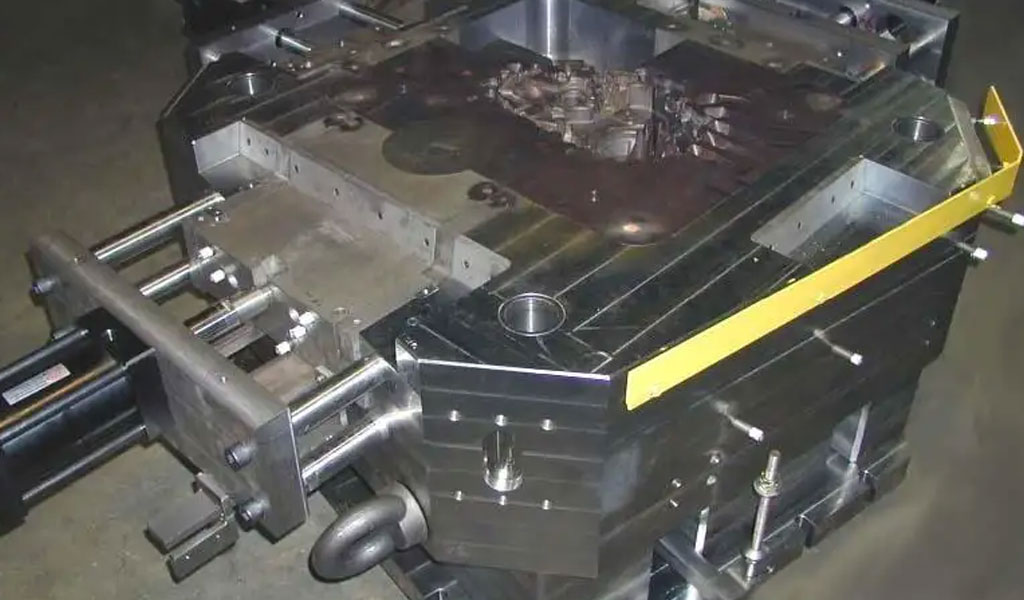

Aluminum Die-Casting Shell

The aluminum die casting shell adopts one-time die-casting molding technology, which is waterproof and explosion-proof, suitable for field use, but the price is high, the flexibility is low, and the size and size changes can only be achieved by modifying the mold. Scope of application: home appliances, medical, instrumentation, automobiles, electronics, radar, television, aerospace, hardware, daily necessities, etc. Process characteristics of aluminum die casting mold: The aluminum die-casting mold is rapidly filled in the row cavity of the die-casting mold under certain conditions under high pressure, and rapidly cooled under a certain pressure.

The die casting process is a process of organically combining and using the three die-casting production elements of the die-casting alloy die-casting machine. Aluminum die-casting molds have the advantages of high accuracy, low surface roughness value and high material utilization rate. Not only can metal parts with complex shapes, clear contours, thin-walled and deep cavities be manufactured, but also other materials can be directly embedded in die-casting parts. to help save valuable materials and processing.

Therefore, the die-casting part has a dense structure, high strength and hardness, and extremely high productivity. However, die castings often have pores and oxide inclusions, which are not suitable for small batch production, the size of die castings is limited, and the types of die casting alloys are limited. The above difference between the aluminum profile shell and the aluminum die-casting shell is shared here.

The convenience of the aluminum profile shell is unmatched by other types of shells, but the aluminum profile shell generally has poor waterproofness and is not suitable for outdoor and harsh environments. For local use, in general, the aluminum profile housing has a wide range of application prospects. China Humen Pingte Precision Die Casting Factory was founded in 1995. It is located in Guangdong Province, bordering Shenzhen and Guangzhou, and facing Hong Kong in the south, with very convenient transportation. Our factory mainly deals in various non-ferrous metal die casting products such as aluminum alloy die-casting and zinc alloy die-casting. Elbow, baby carriage, belt buckle, hardware accessories, and has a complete set of equipment for manufacturing various molds, plus product surface brightness treatment, and can undertake various mold manufacturing.

There are more than 50 employees, including many experienced technicians, 5 mold workers with senior professional titles, and 1 member of Shanghai Mold Association. The company’s workforce is of high quality and skilled in technology. The factory has the technology to smelt aluminum, zinc, copper and other alloy materials, and the factory has passed the quality management system certification ISO9001: 2015 standard.

Main equipment: one 400-ton cold die-casting machine of Hong Kong Lijin brand, one 280-ton cold die casting machine, three 160-ton cold die-casting machines, one 130-ton cold die-casting machine, and one 100-ton cold die-casting machine Taiwan, one 88-ton hot chamber die casting machine and so on. Now the main products are more than 500 kinds. 30% of them are exported to the United States, Japan, Australia, Europe and other countries. The factory has always adhered to the management of “high standards and strict requirements” and the management policy of “quality as the root, reputation as the foundation”, and will provide domestic and foreign merchants with high-quality products and good services.

Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products