With the repetition of the global epidemic, we must pay attention to the processing of mask machine parts. When processing parts, cracks will appear in the parts. The source of the cracks is brought by the abrasive tools in the R&D and design process. No material can be completely without drawbacks. , but the quantity and degree are different. Although we have made efforts in technical operation and other aspects, there are still more disadvantages than metal materials. Also, this does not mean that products with shortcomings will inevitably cause cracks, mainly The thing is that the product is not easy to plastically deform like a metal under the action Read more

This article mainly focuses on the maintenance work of the aluminum alloy high-speed boat hull, and the marine electrical and navigation equipment should be implemented in accordance with the operating instructions. Aluminum alloy boats have many excellent advantages, one of which is low maintenance costs. Easy maintenance and low cost does not mean no maintenance is required. In order to improve the efficiency of operation and reduce costs, it is necessary to work hard on the maintenance of equipment. The paint peeling of aluminum alloy boats below the waterline is a common problem, and it is also the most troublesome problem for ship owners. This is mainly due to the Read more

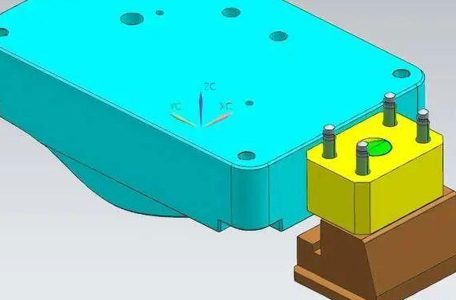

When the customer needs to remove the inclined guide post from the parting surface, when choosing the fixing method of the inclined guide post, the inclined guide post fixing block is preferred to fix the inclined guide post. Solution: 1. Click the menu [Start]-[All Application Modules]-[Injection Mold Wizard]-[Injection Mold Tools]-[Create Block]-[Type] to select [Containing Block], use the inclined guide post cup head and the slider top face, make a 57x 40 x 27mm block as shown below: 2. Click the menu [Insert] – [Combination] – [Difference], and use the package block and the inclined guide column to find the difference, as shown in the following figure: 3. Click the menu Read more

Before the car is overhauled into the factory, it is necessary to clean the outside of the car and the disassembled internal parts, which is stipulated in the inspection of the car entering the factory. The purpose of cleaning the exterior of the car before disintegration is to remove the dust, mud and oil on the exterior, and at the same time, the exterior defects can be found in time, so that the defects can be repaired, so that the disassembly work can be carried out smoothly, and the disassembly site can be kept clean. How To Clean Oxidized Aluminum Engine Parts The oxidized engine parts is cleaned with a Read more

There are many types of aluminum products, such as plates, sheets, foils, extrusions, rods, wires, etc., the definition of aluminum rolling quality “aluminum billets are manufactured into flat products by heating, hot rolling, cold rolling, heat treatment and other processes. “Form” can be in the shape of a plate, sheet, or foil. The product categories of aluminum rolled products are mainly distinguished by thickness, according to the regulations of the Aluminum Association as follows: Aluminum plate: thickness 6.35 (inclusive) mm or more Aluminum sheet: 0.15-6.35mm flat sheet and roll sheet Aluminum foil: thickness 0.15 (not included) mm or less Aluminum alloys can be divided into work-hardening and heat-treated alloys according Read more

Strong Oxidation Capacity The affinity between aluminum and oxygen is very strong. It is easy to combine with oxygen in the air to form a dense and solid Al2O3 film with a thickness of about 0.1 μ m. The melting point is as high as 2050 ℃, far exceeding the melting point of aluminum and aluminum alloys, and the density is very large, about 1.4 times that of aluminum. In the welding process, alumina film will hinder the good bonding between metals and easily cause slag inclusion. The oxide film will also absorb water, which will promote the formation of pores in the weld during welding. These defects will reduce Read more

After electroplating various metals on the surface of aluminum and aluminum alloy, the physical or chemical properties of the surface can be significantly improved. When aluminum and aluminum alloy are used as conductors, electroplating silver on the surface can improve the conductivity of the surface or electrical contact part; In order to make aluminum easy to weld, copper, nickel or tin are electroplated on its surface; In order to improve its wear resistance, thick chrome is electroplated on its surface. In terms of decoration, most of them are actually electroplated. Electroplating on the surface of aluminum and aluminum alloy has been tried for a long time and has been used Read more

The Characteristics Of Aluminum Substrate Surface mount technology (SMT) is adopted; Very effective treatment of heat diffusion in circuit design; Reduce the operating temperature of the product, improve the power density and reliability of the product, and prolong the service life of the product; Reduce product volume and reduce hardware and assembly costs; Replace the fragile ceramic substrate to obtain better mechanical durability. The Structure Of PCB Aluminum Substrate PCB aluminum based copper clad laminate is a kind of metal circuit board material, which is composed of copper foil, thermal insulation layer and metal substrate. Its structure is divided into three layers: Cireuitl. Layer circuit layer: copper clad laminate equivalent Read more