Some customers have too much control over the cost of ordering the platform, and the cast iron plate is too light in weight. Attention should be paid to this kind of plate when machining, because if you are not careful, there will be chattering lines and chipping. There are two things you should pay attention to when using the tablet: 1. Cutting amount: When planing a thin standard cast iron plate, the cutting force and clamping force should be small, so a small cutting depth (about 0.3~0.5mm or less) and feed rate (about 0.1~0.5mm) should be used. 0.25mm/reciprocating stroke), as well as normal cutting speed, and appropriate cooling lubricant for Read more

Precision machine tools paired with advanced cutting tools provide outstanding metal cutting productivity. The tool holder, as the critical interface between the cutting tool and the machine tool spindle, is critical to achieving high productivity. Tool manufacturers offer a variety of toolholder types, each designed to perform optimally in specific machining applications. Therefore, a shop should choose a tool holder based on its specific process and the parts it produces. However, while shops want to use the most advanced machine tool technology and cutting tool materials, they often don’t pay much attention to the selection, application and maintenance of the holder that best suits their specific production needs. All Hilts Read more

The spindle taper holes of machining centers are usually divided into two categories, namely the general system with a taper of 7:24 and the HSK vacuum system with a taper of 1:10. 1.7:24 Taper Universal Tool Holder Universal tool holders with a taper of 7:24 are generally available in five standards and sizes, namely NT (traditional), DIN 69871 (German standard), IS0 7388/1 (international standard), MAS BT (Japanese standard) and ANSI/ASME (American standard). The German standard of the NT type tool holder is DIN 2080. The tool holder is tightened by a pull rod on a traditional machine tool. It is also called ST in China; the other four tool holders Read more

Gear mold laser surface strengthening technology refers to the use of high-energy density laser beams and coatings, or cladding materials to treat the surface of gears or molds in a numerically controlled environment to change the structure or composition of the surface layer to achieve surface phase change strengthening or Enhanced repair techniques. The phase change strengthening process has the advantages of good surface quality, and can control the hardness and the depth of the strengthening layer according to different materials, heat capacity of the workpiece, and different laser processing parameters. The technical factors that affect the strengthening effect in the traditional heat treatment process have changed a lot in Read more

How To Anodize Aluminum?The process of using aluminum or aluminum alloy products as anodes, placing them in an electrolyte solution for electrification treatment, and using electrolysis to form an aluminum oxide film on the surface is called anodizing treatment of aluminum and aluminum alloys. After anodic oxidation, an oxide film of several micrometers—hundreds of micrometers can be formed on the surface of aluminum. Compared with the natural oxide film of aluminum alloy, its corrosion resistance, wear resistance and decoration are obviously improved and improved. The principle of aluminum anodization is essentially the principle of water electrolysis. When the current is passed, the following reactions will take place: At the cathode, Read more

With the repetition of the global epidemic, we must pay attention to the processing of mask machine parts. When processing parts, cracks will appear in the parts. The source of the cracks is brought by the abrasive tools in the R&D and design process. No material can be completely without drawbacks. , but the quantity and degree are different. Although we have made efforts in technical operation and other aspects, there are still more disadvantages than metal materials. Also, this does not mean that products with shortcomings will inevitably cause cracks, mainly The thing is that the product is not easy to plastically deform like a metal under the action Read more

This article mainly focuses on the maintenance work of the aluminum alloy high-speed boat hull, and the marine electrical and navigation equipment should be implemented in accordance with the operating instructions. Aluminum alloy boats have many excellent advantages, one of which is low maintenance costs. Easy maintenance and low cost does not mean no maintenance is required. In order to improve the efficiency of operation and reduce costs, it is necessary to work hard on the maintenance of equipment. The paint peeling of aluminum alloy boats below the waterline is a common problem, and it is also the most troublesome problem for ship owners. This is mainly due to the Read more

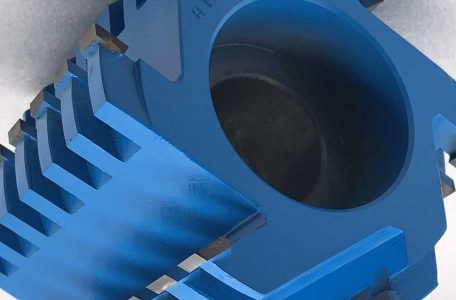

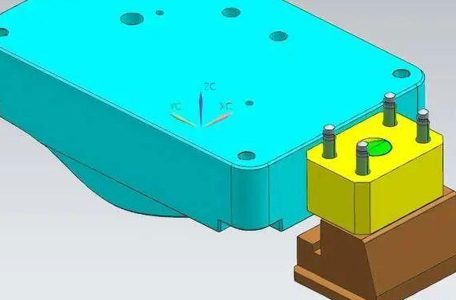

When the customer needs to remove the inclined guide post from the parting surface, when choosing the fixing method of the inclined guide post, the inclined guide post fixing block is preferred to fix the inclined guide post. Solution: 1. Click the menu [Start]-[All Application Modules]-[Injection Mold Wizard]-[Injection Mold Tools]-[Create Block]-[Type] to select [Containing Block], use the inclined guide post cup head and the slider top face, make a 57x 40 x 27mm block as shown below: 2. Click the menu [Insert] – [Combination] – [Difference], and use the package block and the inclined guide column to find the difference, as shown in the following figure: 3. Click the menu Read more

Before the car is overhauled into the factory, it is necessary to clean the outside of the car and the disassembled internal parts, which is stipulated in the inspection of the car entering the factory. The purpose of cleaning the exterior of the car before disintegration is to remove the dust, mud and oil on the exterior, and at the same time, the exterior defects can be found in time, so that the defects can be repaired, so that the disassembly work can be carried out smoothly, and the disassembly site can be kept clean. How To Clean Oxidized Aluminum Engine Parts The oxidized engine parts is cleaned with a Read more

There are many types of aluminum products, such as plates, sheets, foils, extrusions, rods, wires, etc., the definition of aluminum rolling quality “aluminum billets are manufactured into flat products by heating, hot rolling, cold rolling, heat treatment and other processes. “Form” can be in the shape of a plate, sheet, or foil. The product categories of aluminum rolled products are mainly distinguished by thickness, according to the regulations of the Aluminum Association as follows: Aluminum plate: thickness 6.35 (inclusive) mm or more Aluminum sheet: 0.15-6.35mm flat sheet and roll sheet Aluminum foil: thickness 0.15 (not included) mm or less Aluminum alloys can be divided into work-hardening and heat-treated alloys according Read more