The punching process is a fundamental technique in mechanical processing, widely utilized across industries such as automotive, aerospace, electronics, and construction. This metal-forming process involves the use of a punch press to force a tool, called a punch, through a workpiece to create holes, shapes, or patterns. The versatility, efficiency, and precision of punching make it a cornerstone of modern manufacturing. This article explores the application research of the punching process, delving into its principles, technological advancements, material considerations, process optimization, and industrial applications. By examining historical developments, current practices, and future trends, this comprehensive analysis aims to provide a scientific understanding of punching in mechanical processing. Fundamentals of the Read more

The development of a sterilization packaging production line for tubular parts of medical devices is a complex and multifaceted process that involves various stages, including design, engineering, validation, and implementation. This article aims to provide a comprehensive overview of the entire process, highlighting the scientific principles, technological advancements, and regulatory considerations involved. Introduction Medical devices, particularly those with tubular parts, play a crucial role in modern healthcare. These devices are used in a wide range of applications, from surgical procedures to diagnostic tests. Ensuring the sterility of these devices is paramount to prevent infections and ensure patient safety. The development of a sterilization packaging production line for tubular parts of Read more

The design and manufacturing of shoe sole molds are intricate processes that require precise geometric definitions and a high degree of customization. In recent years, advancements in computer numerical control (CNC) machining have provided new capabilities for designing and producing shoe sole molds. One of the critical factors in achieving high precision and efficiency in CNC machining is the use of parametric curve design, integrated with macro instructions. Parametric curve design in CNC machining involves defining a series of curves and surfaces using mathematical parameters rather than fixed coordinates. These curves can then be adjusted dynamically based on the input parameters, offering a level of flexibility that is essential in Read more

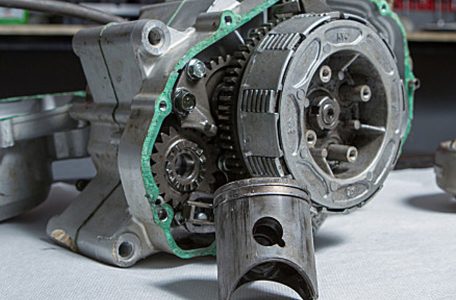

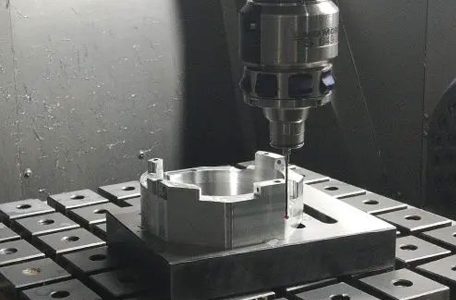

Motorcycle parts are crafted using a wide range of manufacturing processes, with CNC (Computer Numerical Control) machining standing out as a primary method for creating precision components in the motorcycle industry. The use of CNC machining in the production of motorcycle parts is driven by its numerous advantages, including high precision, versatility, speed, and cost-effectiveness. This article explores why CNC machining has become indispensable for manufacturing motorcycle parts and how it has shaped the industry. Overview of CNC Machining CNC machining refers to a manufacturing process in which pre-programmed computer software controls the movement of machinery and tools. These tools are used to cut, shape, and finish materials such as Read more

Machining sleeve parts is a critical process in many industries, including automotive, aerospace, oil and gas, and manufacturing. These cylindrical components, often designed to function as bushings, spacers, or protective casings, require precise machining to meet stringent specifications. Determining the cost of machining sleeve parts involves a variety of factors, including material, design complexity, production volume, and finishing requirements. This article delves into the intricacies of calculating charges for machining sleeve parts, highlighting key considerations that influence pricing in the machining industry. Material Selection and Cost Implications Material choice significantly impacts the cost of machining sleeve parts. The selection depends on the application, mechanical properties, and environmental factors such as Read more

Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on the surface of aluminum alloys. This process enhances the material’s corrosion resistance, wear resistance, and provides a better surface for adhesion of paints and primers. The process is widely used in aerospace, automotive, architectural, and consumer goods industries. This article provides an in-depth look at the various specifications and standards related to anodizing aluminum alloys. The content is structured to cover the anodizing process, key standards, material considerations, and quality assurance protocols. It also examines the impact of anodizing on mechanical properties, discusses common defects and their prevention, and highlights the importance of environmental Read more

Runout is a critical concept in the field of machining, referring to the deviation of a tool or workpiece from its intended path or axis during rotation. This deviation can have significant implications for the accuracy, precision, and surface finish of the machined part, making it a key consideration in various manufacturing processes. Understanding the causes, types, measurement techniques, and effects of runout is essential for ensuring the quality and efficiency of machining operations. 1. Definition and Overview Runout in machining is the deviation of a rotating tool or workpiece from its true axis. It can occur in various forms, including radial, axial, and face runout. Each type of runout Read more

Aluminum alloy materials are widely used in medical equipment, aerospace, new energy vehicles, military industry and other industries. As its own unique advantages, such as low density, high specific strength and specific stiffness, and good corrosion resistance, it is one of the preferred processing materials for customers. Due to the wide application of aluminum alloy materials, its processing technology is becoming more and more mature, and aluminum alloy five-axis machining is one of them. For customers, aluminum alloy five-axis machining also has the following benefits: The Benefits Of Aluminum Alloy 5 Axis Machining For Customers First of all, aluminum alloy five-axis machining can greatly improve machining accuracy and quality. Compared Read more

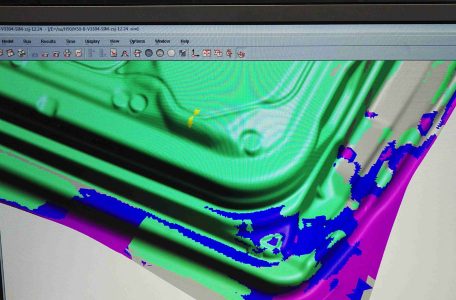

Manufactured parts produced in the automotive and aerospace industries are becoming increasingly complex. Tolerances must meet relevant quality control standards, and today they are becoming increasingly complex and optimized. In addition, the customer is also requiring the supplier to implement compliance controls, whereas previously the compliance of batches was assessed using only input control samples. The above situation puts a lot of pressure on the quality control team. How should we deal with the ever-increasing tolerance pressures? This article will explore several possible solutions. In the automotive and aerospace industries, CNC Machining tolerances must meet quality control requirements, and tolerance requirements are constantly evolving. First, let’s understand the reasons for Read more

Machining accuracy is the degree to which the actual size, shape and position of the surface of the machined parts conform to the ideal geometric parameters required by the drawings. The ideal geometric parameter, for the size, is the average size; for the surface geometry, it is the absolute circle, cylinder, plane, cone and straight line, etc.; for the mutual position between the surfaces, it is the absolute parallel , vertical, coaxial, symmetrical, etc. The deviation of the actual geometric parameters of the part from the ideal geometric parameters is called the machining error. The Introduction Of Cnc Machining Parts Machining accuracy is mainly used to produce products, and machining Read more