The punching process is a fundamental technique in mechanical processing, widely utilized across industries such as automotive, aerospace, electronics, and construction. This metal-forming process involves the use of a punch press to force a tool, called a punch, through a workpiece to create holes, shapes, or patterns. The versatility, efficiency, and precision of punching make it a cornerstone of modern manufacturing. This article explores the application research of the punching process, delving into its principles, technological advancements, material considerations, process optimization, and industrial applications. By examining historical developments, current practices, and future trends, this comprehensive analysis aims to provide a scientific understanding of punching in mechanical processing. Fundamentals of the Read more

Guide

Aluminum 2024 and Aluminum 7075 are two of the most commonly used aluminum alloys in aerospace, automotive, and structural applications. Both alloys are valued for their high strength-to-weight ratios, corrosion resistance, and machinability, but they differ significantly in their chemical composition, mechanical properties, and applications. Chemical Composition Aluminum 2024 is primarily an aluminum-copper alloy. It contains approximately 3.8-4.9% copper, 0.3-0.9% manganese, 1.2-1.8% magnesium, and small amounts of other elements such as iron and silicon. The high copper content gives 2024 aluminum its excellent strength but also makes it more susceptible to corrosion compared to other aluminum alloys. Aluminum 7075, on the other hand, is an aluminum-zinc alloy with significant amounts Read more

High-speed wire cutting three-axis linkage machining is a cutting-edge technology used in the manufacturing of multi-dimensional complex ruled surfaces. This advanced machining process combines the precision of wire electrical discharge machining (WEDM) with the flexibility of three-axis linkage, enabling the production of intricate and highly accurate parts. This article delves into the research, applications, and technological advancements in this field, providing a comprehensive overview for both academic and industrial purposes. Introduction to Wire Cutting and Three-Axis Linkage Wire cutting, specifically Wire Electrical Discharge Machining (WEDM), is a non-traditional machining process that uses a thin wire as an electrode to cut through electrically conductive materials. The wire, typically made of brass Read more

The development of a sterilization packaging production line for tubular parts of medical devices is a complex and multifaceted process that involves various stages, including design, engineering, validation, and implementation. This article aims to provide a comprehensive overview of the entire process, highlighting the scientific principles, technological advancements, and regulatory considerations involved. Introduction Medical devices, particularly those with tubular parts, play a crucial role in modern healthcare. These devices are used in a wide range of applications, from surgical procedures to diagnostic tests. Ensuring the sterility of these devices is paramount to prevent infections and ensure patient safety. The development of a sterilization packaging production line for tubular parts of Read more

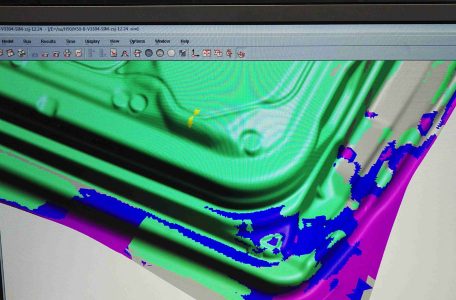

Computer-Aided Manufacturing (CAM) technology has revolutionized the manufacturing industry, particularly in the realm of five-axis machining. Five-axis machining refers to the process of manufacturing parts using a machine tool that can move in five different axes simultaneously. This advanced machining technique allows for the creation of complex geometries that would be impossible or highly inefficient to produce using traditional three-axis machining. CAM technology plays a crucial role in five-axis machining by providing the necessary software tools to design, simulate, and optimize the machining process. This article delves into the intricacies of CAM technology for five-axis machining, exploring its historical development, key components, advantages, applications, and future trends. Historical Development of Read more

The design and manufacturing of shoe sole molds are intricate processes that require precise geometric definitions and a high degree of customization. In recent years, advancements in computer numerical control (CNC) machining have provided new capabilities for designing and producing shoe sole molds. One of the critical factors in achieving high precision and efficiency in CNC machining is the use of parametric curve design, integrated with macro instructions. Parametric curve design in CNC machining involves defining a series of curves and surfaces using mathematical parameters rather than fixed coordinates. These curves can then be adjusted dynamically based on the input parameters, offering a level of flexibility that is essential in Read more

To provide a thorough and scientific analysis of the advantages of the fourth displacement curve acceleration and deceleration method in CNC machining, it’s essential to delve into its underlying principles, application, and impact on machining efficiency. This method, often employed in advanced CNC systems, enhances both the precision and efficiency of machining processes by optimizing toolpath control. It can reduce machining time, improve surface finish, and mitigate tool wear—all while maintaining the quality of the final product. In CNC machining, the acceleration and deceleration of the tool are critical for controlling the dynamic forces acting on both the workpiece and the tool. These forces affect the quality of the cut, Read more

CNC (Computer Numerical Control) machining plays a crucial role in the manufacturing of parts for food processing machinery. The precision and flexibility that CNC technology offers allow manufacturers to create components that meet the stringent requirements of the food industry, where hygiene, durability, and efficiency are essential. In this article, we will explore the top 20 CNC machined parts and components used in food processing machinery. These parts are integral to ensuring the smooth operation of machines that handle everything from raw ingredient processing to packaging and distribution. 1. Shafts Shafts are one of the most critical components in food processing machinery, used for transmitting mechanical power and rotary motion. Read more

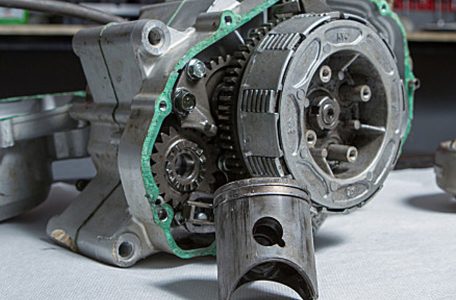

Motorcycle parts are crafted using a wide range of manufacturing processes, with CNC (Computer Numerical Control) machining standing out as a primary method for creating precision components in the motorcycle industry. The use of CNC machining in the production of motorcycle parts is driven by its numerous advantages, including high precision, versatility, speed, and cost-effectiveness. This article explores why CNC machining has become indispensable for manufacturing motorcycle parts and how it has shaped the industry. Overview of CNC Machining CNC machining refers to a manufacturing process in which pre-programmed computer software controls the movement of machinery and tools. These tools are used to cut, shape, and finish materials such as Read more

Machining sleeve parts is a critical process in many industries, including automotive, aerospace, oil and gas, and manufacturing. These cylindrical components, often designed to function as bushings, spacers, or protective casings, require precise machining to meet stringent specifications. Determining the cost of machining sleeve parts involves a variety of factors, including material, design complexity, production volume, and finishing requirements. This article delves into the intricacies of calculating charges for machining sleeve parts, highlighting key considerations that influence pricing in the machining industry. Material Selection and Cost Implications Material choice significantly impacts the cost of machining sleeve parts. The selection depends on the application, mechanical properties, and environmental factors such as Read more