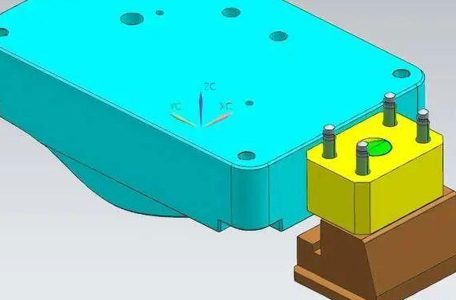

When the customer needs to remove the inclined guide post from the parting surface, when choosing the fixing method of the inclined guide post, the inclined guide post fixing block is preferred to fix the inclined guide post. Solution: 1. Click the menu [Start]-[All Application Modules]-[Injection Mold Wizard]-[Injection Mold Tools]-[Create Block]-[Type] to select [Containing Block], use the inclined guide post cup head and the slider top face, make a 57x 40 x 27mm block as shown below: 2. Click the menu [Insert] – [Combination] – [Difference], and use the package block and the inclined guide column to find the difference, as shown in the following figure: 3. Click the menu Read more

Guide

Before the car is overhauled into the factory, it is necessary to clean the outside of the car and the disassembled internal parts, which is stipulated in the inspection of the car entering the factory. The purpose of cleaning the exterior of the car before disintegration is to remove the dust, mud and oil on the exterior, and at the same time, the exterior defects can be found in time, so that the defects can be repaired, so that the disassembly work can be carried out smoothly, and the disassembly site can be kept clean. How To Clean Oxidized Aluminum Engine Parts The oxidized engine parts is cleaned with a Read more

The wheel hub, also known as the rim, is the barrel-shaped, center-mounted part of the tire that is used to support the tire. Common car wheels include steel wheels and aluminum alloy wheels. Steel wheels have high strength and are often used in large trucks; however, steel wheels are heavy in quality and have a single shape, which does not conform to today’s low-carbon and fashionable concepts, and is gradually being replaced by aluminum alloy wheels. The Advantages Of Aluminum Alloy Wheels Compared with steel car wheels, the advantages of aluminum alloy wheels are obvious: the density is small, about 1/3 of steel, which means that the same volume of Read more

Aluminum CNC Machining Cost CNC machining aluminum parts has higher precision than ordinary deep machining, so the price of CNC machining is higher than that of ordinary deep machining. So how is the price of CNC aluminum parts calculated? 1. Calculate the processing fee according to the processing process This calculation method is very simple, that is, how much does it cost to punch a hole, how much does it cost to tap a thread, how much does it cost to mill a square centimeter… Then multiply by the number of holes to be machined, the area of milling, and add up these amounts It is the price of CNC Read more

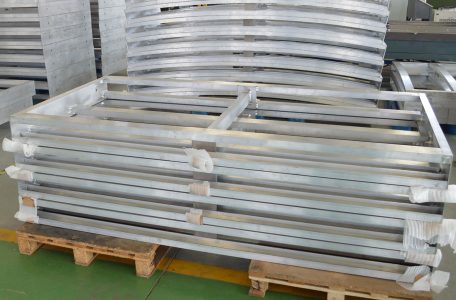

There are many types of aluminum products, such as plates, sheets, foils, extrusions, rods, wires, etc., the definition of aluminum rolling quality “aluminum billets are manufactured into flat products by heating, hot rolling, cold rolling, heat treatment and other processes. “Form” can be in the shape of a plate, sheet, or foil. The product categories of aluminum rolled products are mainly distinguished by thickness, according to the regulations of the Aluminum Association as follows: Aluminum plate: thickness 6.35 (inclusive) mm or more Aluminum sheet: 0.15-6.35mm flat sheet and roll sheet Aluminum foil: thickness 0.15 (not included) mm or less Aluminum alloys can be divided into work-hardening and heat-treated alloys according Read more

What Is 7075 Aluminum 7075 Aluminum is a cold-worked wrought alloy that is stronger than mild steel. 7075 aluminum alloy is one of the strongest commercial alloys. 7075 aluminum alloy has a compact structure and strong corrosion resistance, which is the best for aviation and marine plates. Normal corrosion resistance, good mechanical properties and anodic reaction. The fine grains provide better deep drilling performance and enhanced tool wear resistance. Material Advantages: This alloy is a high-strength heat-treatable alloy, easy to process, and has strong wear resistance, so it has good mechanical properties, as well as corrosion resistance and oxidation resistance. Product Accuracy: The dimensional tolerances are processed in accordance with Read more

What Is 5052 Aluminum 5052 aluminum alloy belongs to Al-Mg alloy, which is widely used, especially the construction industry cannot do without this alloy. It is one of the most promising alloys. Good corrosion resistance, excellent weldability, good cold workability, and moderate strength. The main alloying element of 5052 aluminum alloy is magnesium, which has good formability, corrosion resistance, weldability, and medium strength. Rivets, hardware products, electrical-apparatus shells, etc. The Process Properties Of 5052 Aluminum The Formability Of 5052 Aluminum The alloy has good plasticity in hot state. The forging and die forging temperature is 420~475°C, and the hot deformation with the deformation rate > 80% is carried out in Read more

In our daily life, we often see widely used aluminum profile housings and aluminum die casting housings. Compared with aluminum die-casting housings, aluminum profile housings have their own advantages. Aluminum profile housings are various housings made of aluminum alloys. Convenience, high flexibility, high grade, can effectively increase the added value of products, and can be widely used in the electronics industry, generally including aluminum profile shells and aluminum die-casting shells. So what is the difference between aluminum profile shell and aluminum die-casting shell? Next, BE-CU.COM author will introduce it. Aluminum Profile Shell The aluminum profile shell is a shell processed on the aluminum profile obtained by aluminum drawing. It has Read more

With the rapid development of industrial mechanization, the development of radiators is getting faster and faster. In our daily life, radiators are everywhere. Automobile radiators, communication base radiators, locomotive radiators, wind radiators, power radiators, Electronic radiator, electrical radiator, LED lamp radiator, mechanical equipment radiator, new energy radiator, power semiconductor radiator, inverter radiator, CNC machine tool radiator… CPU, graphics card, motherboard chipset, Hard drives, cases, power supplies, and even optical drives and memory all require heat sinks. At present, extruded aluminum profiles are commonly used in the market to make radiators. The cooling fins can be made very thin, and the heat dissipation area can be expanded to the greatest extent. Read more

Have you ever heard about a product prototype? It seems like a very technical and specific word, but the truth is that it is so familiar that you can’t even imagine it. Due to this, in this note we will tell you what a prototype of a product is, what it is for and what the guidelines are for making one. A fundamental part of the development of a product or rapid prototyping service is born as a result of a prototype. In fact, the device you are using to read this text arose from prototyping planning and extensive project execution. Therefore, today you will learn how to design a Read more