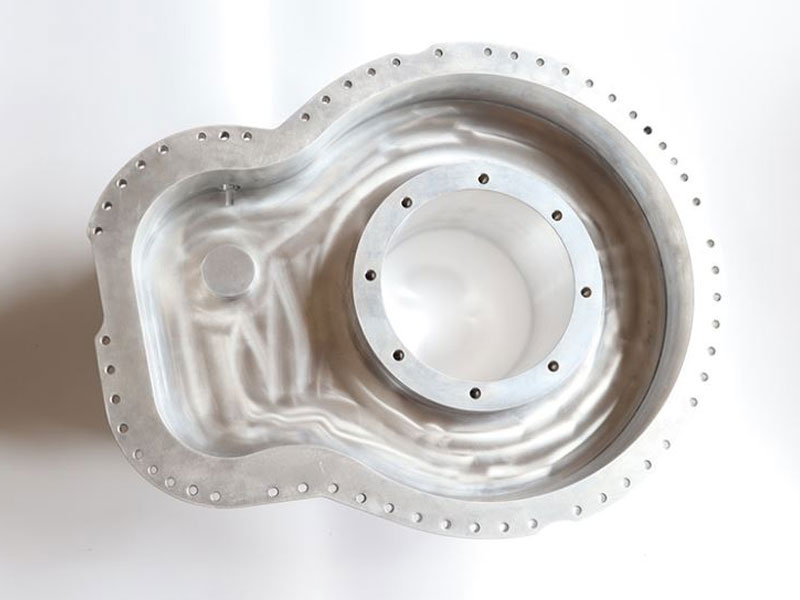

20KG Aluminum 5083 Automotive Box Parts

20KG Aluminum 5083 Automotive Box Parts is one of the largest products our company has processed so far. It uses imported raw materials. After machining, the product still weighs about 20KG without any surface treatment. The structure is more complex, the technical content is high, the reproducibility is low, the cost is high, and the machining cycle is long. At present, the more and more extensive application of complex parts has put forward higher requirements for machining technology. The rapid development of industrial economy and the increasing demand for complex parts have prompted complex parts machining manufacturers to pay more and more attention to the research and optimization of complex parts machining technology.

- Product name: CNC machining of large auto parts

- Product size: 550mm*440mm*200mm (customized according to the picture)

- Material: EN AW 5083/EN AW 6082

- Machining tolerance: up to ±0.02mm

- Quality inspection: 100% inspection

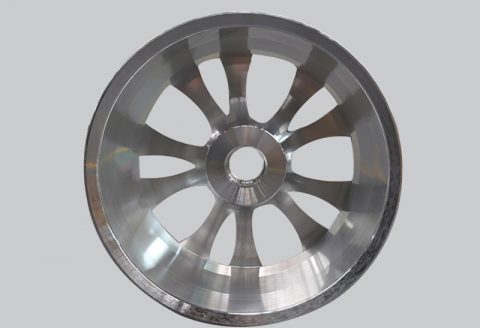

Box-type parts generally refer to parts with more than one hole system, a cavity inside, and a certain proportion in the length, width and height directions. Such parts are used more in machine tool, automobile, aircraft manufacturing and other industries. Such parts generally require multi-station hole system and plane processing, with high tolerance requirements, especially strict geometric tolerance requirements, usually through milling, drilling, expanding, boring, reaming, countersinking, tapping and other processes. There are many tools, it is difficult to process on ordinary machine tools, the number of tooling sets is high, the cost is high, the processing cycle is long, and multiple clamping, alignment, and manual measurements are required. The important thing is that accuracy is difficult to guarantee. Machining centers for machining box-type parts, when there are many machining stations, parts that require multiple rotation angles of the table to complete, generally choose horizontal boring and milling machining centers, when there are fewer machining stations and the span is not When large, a vertical machining center is optional, and machining is performed from one end. CNC machining centers play a particularly important role in the machining of complex curved surfaces in the machinery manufacturing industry, especially in the aerospace industry. It is difficult or even impossible to complete complex curved surfaces by ordinary machining methods. In my country, the traditional method is to use precision casting, and it is conceivable that its precision is very low.

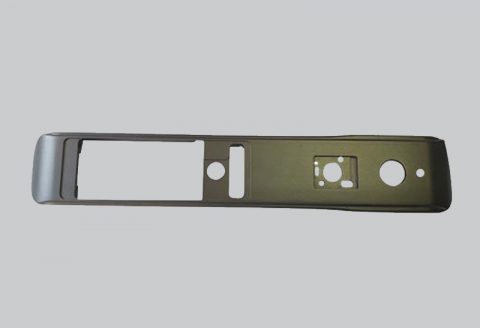

Categories: 5 Axis Machining Parts, 6082, Automotive, Cnc Milling Parts