The First Is The Problem Of Seam Angle Or Poor Welding

There are only two reasons for this problem, the first is that the orifice is small, the metal flow in the welding cavity is not enough to make the metal without sufficient hydrostatic pressure in the welding chamber, the product does not flow out of the welding die hole, resulting in The existence of gaps in welding items; the second is caused by excessive lubrication and adverse effects of lubrication caused by poor welding behavior of hollow profiles.

Followed by the concave or arcuate convex surface of the aluminum profile wall

There are actually two reasons for this problem. The first aspect is the important reason for the concave arcuate surface of the hollow aluminum profile exit profile wall: the working belt of the core of the aluminum profile is lower than the working belt of the lower die hole, and the core is working. The effective data length of the belt is too short; the other aspect is the reason why the hollow aluminum profile wall protrudes: the mold is used for too long, the mold core working belt is seriously worn, grooves appear, the friction resistance is increased, and the metal flow is slow. The hollow profile walls protrude.

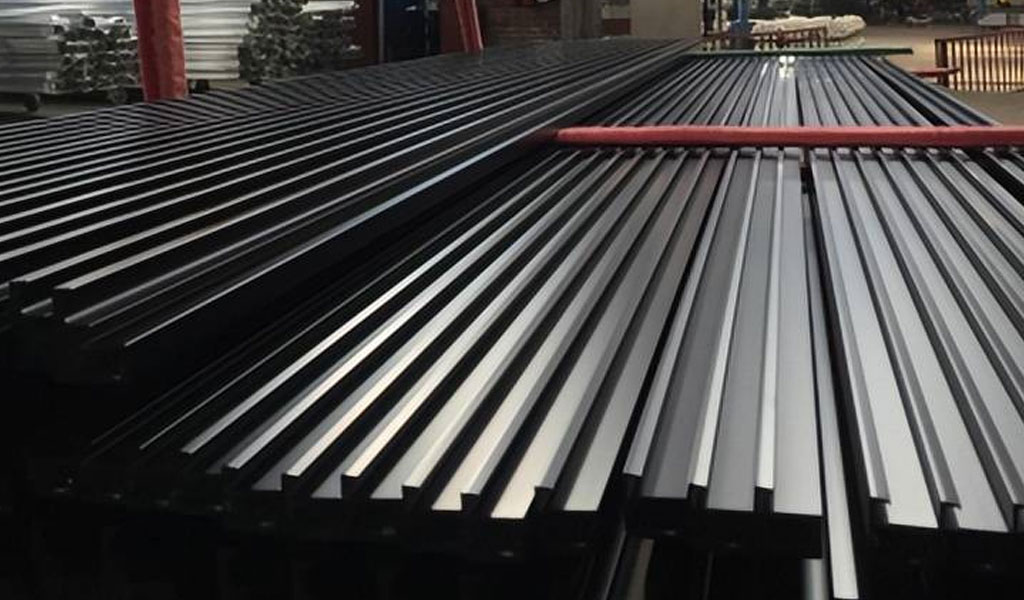

Then there are stripes on the surface of the aluminum profile

There are 5 main reasons for this problem. One is the stripe on the cell surface caused by insufficient or excessive metal supply in the profile and the inner branches and threaded holes; the other is the surface profile of the stripe in the junction area caused by the shunt bridge; the third is the profile. The problems existing in the design process of the cross-sectional view are that due to the large wall thickness difference of various profiles, the part where the length of the working belt changes abruptly produces a striped color difference after anodization; the fourth is that the cooling capacity of the metal extrusion machine is not enough, resulting in anodizing. Black stripe area; the quality of the fifth blank itself is not good, which affects the color difference of the stripe after the material is anodized.

And finally there is an unreasonable performance in a way that produces bending and twisting

The reasons can be found from three aspects. The first is the unreasonable use of the working belt of the die core and the lower die hole, which causes uneven distribution of the flow velocity on the metal surface of each part of the profile; When dealing with asymmetric positions, the metal current supply is uneven, resulting in uneven metal flow; the third is that the shunt hole is irregularly processed or there is an obstruction on the mold core that hinders the flow of Chinese metal enterprises.

In addition, BE-CU reminds that in the production of aluminum products, it is inevitable that the quality of aluminum production will be affected by a little human operation or machine reasons, but the most important thing is to find the problems as soon as possible, analyze the specific problems in detail, and find solutions. !

In addition, BE-CU reminds that in the production of aluminum products, it is inevitable that the quality of aluminum production will be affected by a little human operation or machine reasons, but the most important thing is to find the problems as soon as possible, analyze the specific problems in detail, and find solutions. !Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products