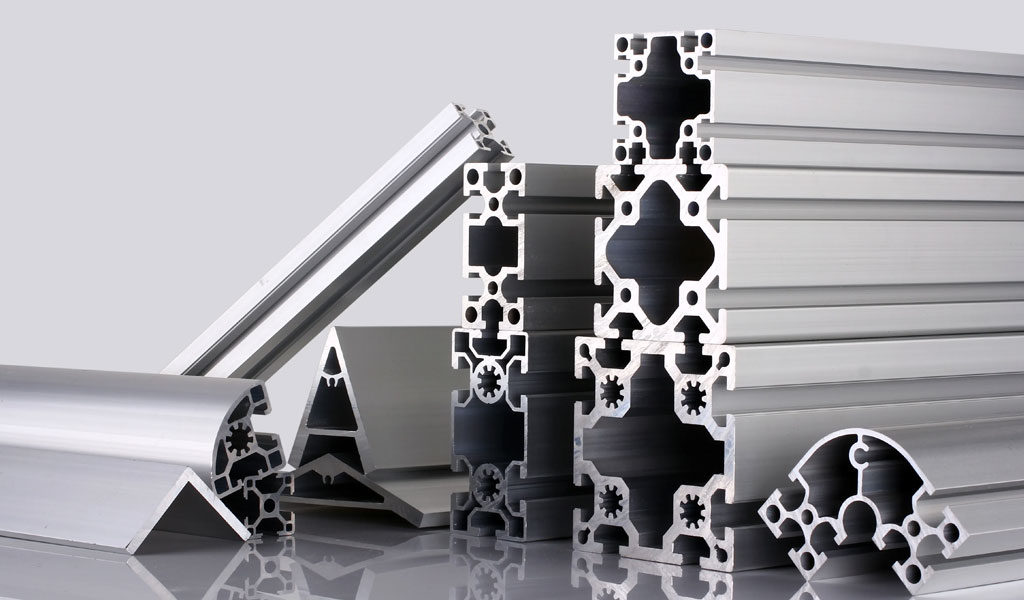

Technical measures to improve the uniform fluidity of metals:

When extruding complex industrial aluminum profiles, the flow of metal is very uneven, the metal flow is slow in the thin wall part, and the metal flow in the thick wall part is fast. If no measures are taken to allow it to flow freely, additional stress will be generated in the industrial aluminum profile, resulting in structural and performance defects of the industrial aluminum profile and distortion of the geometric dimensions.

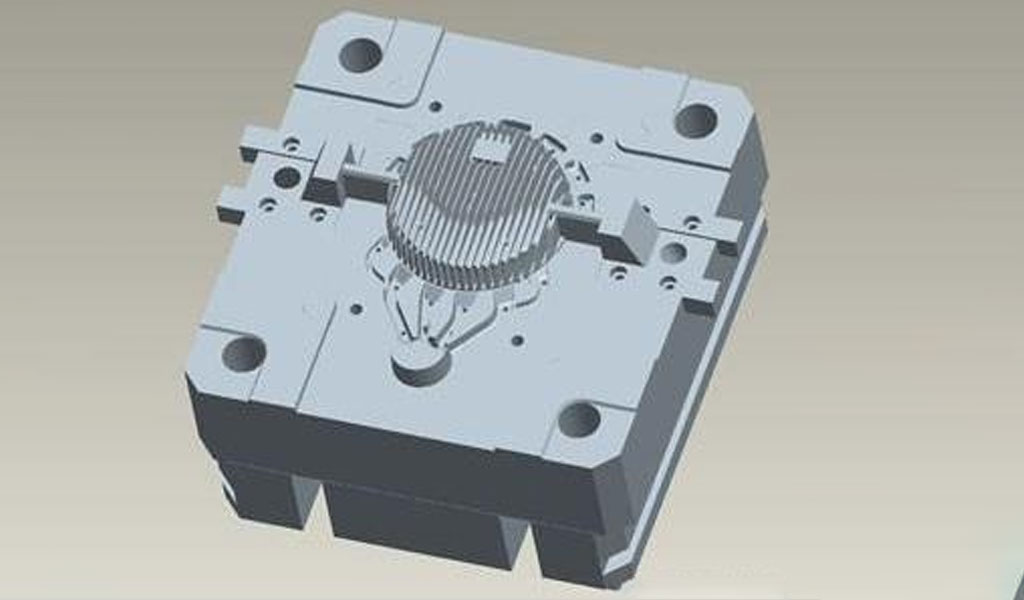

Empty knife for industrial aluminum profile mold

The exit diameter of the industrial aluminum profile mold is also called the empty knife. Strictly speaking, the part of the mold exit diameter larger than the diameter of the working belt of the mold hole is the empty knife. If the empty knife is too large, it may affect the strength performance of the mold; if the empty knife is too small, it will scratch the surface of industrial aluminum products. Generally, the outlet diameter is 4-5mm larger than the diameter of the sizing belt.

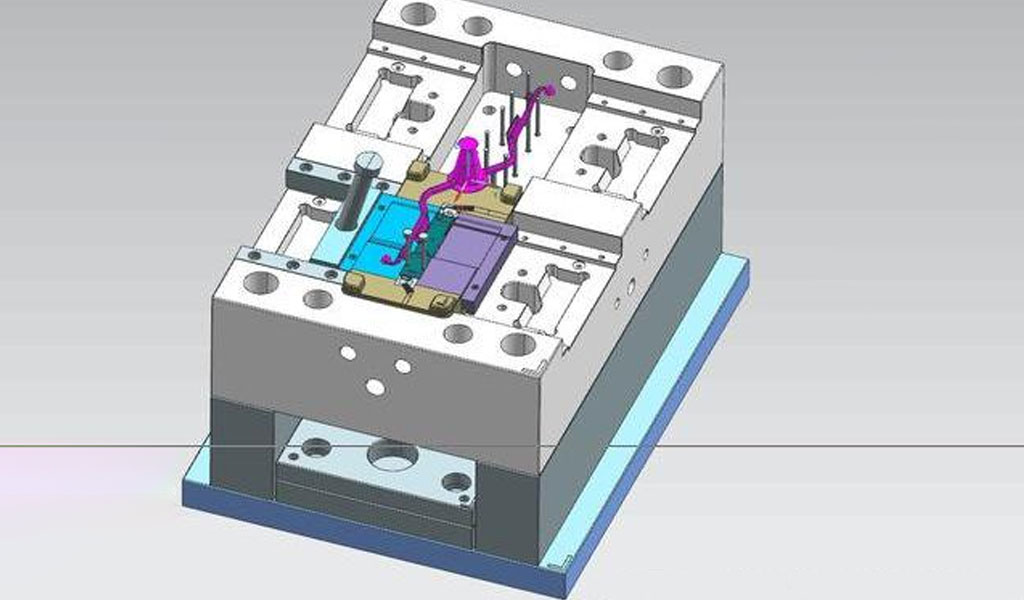

Heating of industrial aluminum extrusion die:

In the process of hot extrusion of industrial aluminum profiles, the tools and molds that are in direct contact with the ingot need to be preheated. The temperature of the tool and mold heating furnace is generally set at 400 °C, and it is best to set the temperature at 450 °C under special circumstances. The mold needs to be kept warm for more than 1 hour after it reaches the temperature in the holding furnace; there are two methods for heating the extrusion cylinder of industrial aluminum profiles: one is to heat it in a tool furnace, and the holding time is not less than 6 hours. The machine is installed by docking. After installation, use its own heating device to keep warm and extrude at a certain temperature. This method is less time-consuming, but it is installed in a hot state, which is inconvenient to operate and increases labor intensity. Another method is to directly use the extrusion cylinder to heat, but it takes a long time and affects the production progress.Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products