What are the causes of surface defects, dull color and rough surface of aluminum profiles? It can be mainly divided into two reasons. One is that the raw material aluminum ingots used are impure, and the profiles are extruded from aluminum rods doped with scrap aluminum. The second is caused by improper operation in the production process. The specific reasons are as follows:

- The raw materials used are doped with scrap aluminum

- Uneven ratio of raw materials in the production process

- During the production process, the acid content of the bath liquid is too high, and the acid corrosion causes the surface to be rough

- If the copper content in the bath is too high, a layer of metallic copper color will be formed on the surface of the produced profiles, resulting in dull color

- Improper die casting during production

- Insufficient deformation during processing

The above 6 points can cause the surface of industrial aluminum profiles to be rough and dull in color. A professional aluminum profile manufacturer is strictly controlled in the process of producing profiles, and the materials are all quality inspected when they leave the factory. In fact, the price of profiles is relatively transparent, so manufacturers use pure aluminum extrusion profiles, and the price will be higher than that of extruded materials doped with scrap aluminum. Therefore, when you find a manufacturer whose price is too affordable, it is recommended that you consider carefully. Either the raw material is impure or the “defective product” whose production and processing technology does not meet the standard.

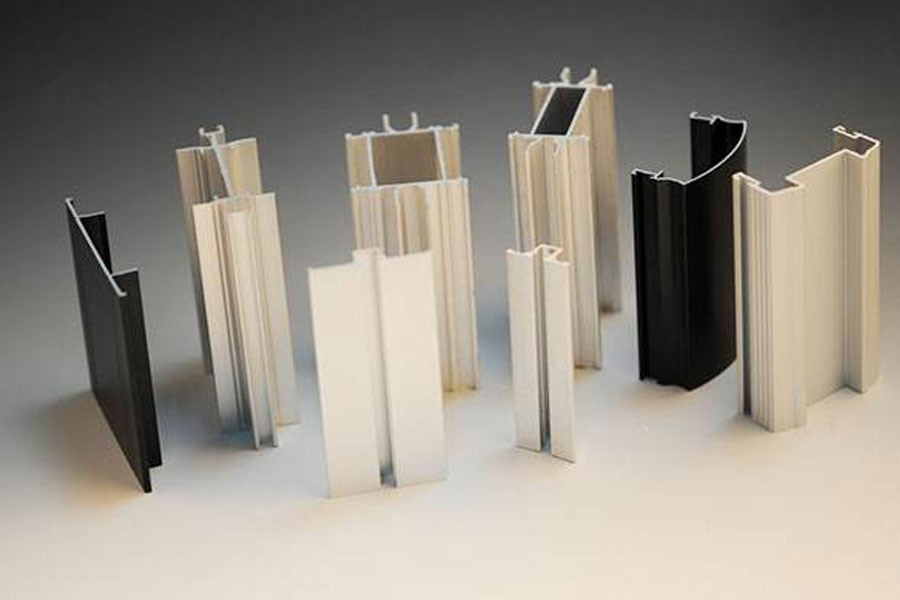

Be-cu aluminum machining china prototype company service include : aluminum cnc turning, aluminum milling service, aluminum extrusions, 5 axis machining aluminum, swiss machining aluminum, aluminum guide,aluminum products