Today, there is a growing demand for orthopaedic replacement and rehabilitation devices. Medical parts include artificial joints as well as artificial boards, rods and nails used to repair or strengthen parts of the body that people have damaged following an accident or illness. With the general increase in human lifespan, more and more elderly people suffer from arthritis and osteoporosis, which leads to the growing demand for orthopaedic replacement devices. The global trend of weight gain and obesity puts more stress on human bones and joints. In addition, the lifestyles of most people are changing, from lack of physical activity to increased sports participation, further increasing the demand for replacement Read more

In recent years, with the continuous maturity of oxidation aluminum parts technology, its application field has been further expanded, and gradually extended to various industries including ceramic machining products. In recent years, with the rapid development of the ceramic industry, a large number of ceramic composite materials have been used in many projects. In addition, alumina, as a very important component in ceramic materials, has a very wide range of applications. This is mainly determined by the properties of alumina materials. Alumina not only has strong hardness, but also has very stable chemical properties. In addition, alumina also has the characteristics of high wear resistance and high melting point. Because Read more

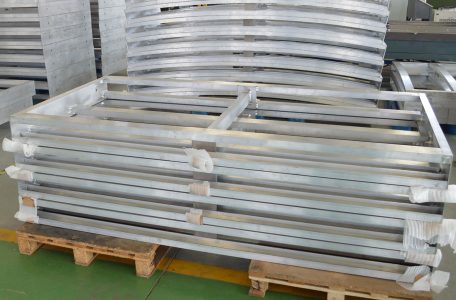

The Process Measures To Reduce Deformation Of Aluminum Machining 1. Reduce the internal stress of the blank Natural or artificial aging and vibration treatment can partially eliminate the internal stress of the blank. Pre-processing is also an effective process method. For larger blanks, due to the large allowance, the deformation after aluminum precision cnc machining is also large. If the excess part of the blank is pre-processed and the allowance of each part is reduced, it can not only reduce the cnc machining deformation of the subsequent process, but also release a part of the internal stress after pre-processing for a period of time. For example, the picture above shows Read more

The wheel hub, also known as the rim, is the barrel-shaped, center-mounted part of the tire that is used to support the tire. Common car wheels include steel wheels and aluminum alloy wheels. Steel wheels have high strength and are often used in large trucks; however, steel wheels are heavy in quality and have a single shape, which does not conform to today’s low-carbon and fashionable concepts, and is gradually being replaced by aluminum alloy wheels. The Advantages Of Aluminum Alloy Wheels Compared with steel car wheels, the advantages of aluminum alloy wheels are obvious: the density is small, about 1/3 of steel, which means that the same volume of Read more

Aluminum CNC Machining Cost CNC machining aluminum parts has higher precision than ordinary deep machining, so the price of CNC machining is higher than that of ordinary deep machining. So how is the price of CNC aluminum parts calculated? 1. Calculate the processing fee according to the processing process This calculation method is very simple, that is, how much does it cost to punch a hole, how much does it cost to tap a thread, how much does it cost to mill a square centimeter… Then multiply by the number of holes to be machined, the area of milling, and add up these amounts It is the price of CNC Read more

What Is 7075 Aluminum 7075 Aluminum is a cold-worked wrought alloy that is stronger than mild steel. 7075 aluminum alloy is one of the strongest commercial alloys. 7075 aluminum alloy has a compact structure and strong corrosion resistance, which is the best for aviation and marine plates. Normal corrosion resistance, good mechanical properties and anodic reaction. The fine grains provide better deep drilling performance and enhanced tool wear resistance. Material Advantages: This alloy is a high-strength heat-treatable alloy, easy to process, and has strong wear resistance, so it has good mechanical properties, as well as corrosion resistance and oxidation resistance. Product Accuracy: The dimensional tolerances are processed in accordance with Read more

What Is 5052 Aluminum 5052 aluminum alloy belongs to Al-Mg alloy, which is widely used, especially the construction industry cannot do without this alloy. It is one of the most promising alloys. Good corrosion resistance, excellent weldability, good cold workability, and moderate strength. The main alloying element of 5052 aluminum alloy is magnesium, which has good formability, corrosion resistance, weldability, and medium strength. Rivets, hardware products, electrical-apparatus shells, etc. The Process Properties Of 5052 Aluminum The Formability Of 5052 Aluminum The alloy has good plasticity in hot state. The forging and die forging temperature is 420~475°C, and the hot deformation with the deformation rate > 80% is carried out in Read more

Have you ever heard about a product prototype? It seems like a very technical and specific word, but the truth is that it is so familiar that you can’t even imagine it. Due to this, in this note we will tell you what a prototype of a product is, what it is for and what the guidelines are for making one. A fundamental part of the development of a product or rapid prototyping service is born as a result of a prototype. In fact, the device you are using to read this text arose from prototyping planning and extensive project execution. Therefore, today you will learn how to design a Read more

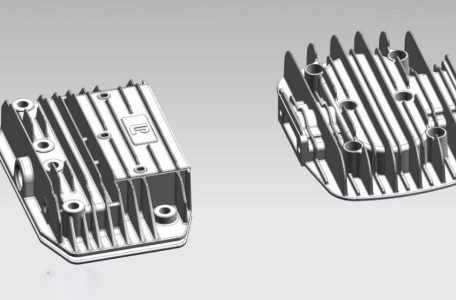

In the process of starting production of aluminum die-casting molds, the mold must be preheated to prevent the appearance of cracks caused by the sudden encounter of hot metal liquid in the cold mold. For more complex molds, blowtorch, liquefied gas, and good conditions With a mold temperature machine, relatively simple molds can be preheated by slow injection. If the mold is equipped with neutron control, pay attention to prohibit the signal line between the die-casting machine and the mold from having joints. The reason is very clear. In daily production, it is difficult to avoid water on the signal line, or the joints are easily broken. , resulting in Read more

Wheel hub, also known as rim, is a barrel shaped part of the tire inner contour used to support the tire, and the center is assembled on the shaft. Common automobile wheels include steel wheels and aluminum alloy wheels. Steel wheel hub has high strength and is often used in large trucks; However, the steel wheel hub has heavy quality and single shape, which is not in line with today’s low-carbon and fashionable concept, and is gradually replaced by aluminum alloy wheel hub. The wheels on the market can be divided into steel wheels and alloy wheels according to their materials. The main advantage of steel wheel hub is that Read more