Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on the surface of aluminum alloys. This process enhances the material’s corrosion resistance, wear resistance, and provides a better surface for adhesion of paints and primers. The process is widely used in aerospace, automotive, architectural, and consumer goods industries. This article provides an in-depth look at the various specifications and standards related to anodizing aluminum alloys. The content is structured to cover the anodizing process, key standards, material considerations, and quality assurance protocols. It also examines the impact of anodizing on mechanical properties, discusses common defects and their prevention, and highlights the importance of environmental Read more

Guide

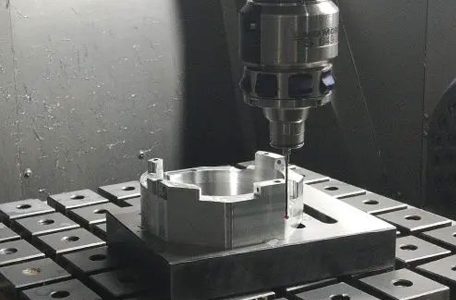

Runout is a critical concept in the field of machining, referring to the deviation of a tool or workpiece from its intended path or axis during rotation. This deviation can have significant implications for the accuracy, precision, and surface finish of the machined part, making it a key consideration in various manufacturing processes. Understanding the causes, types, measurement techniques, and effects of runout is essential for ensuring the quality and efficiency of machining operations. 1. Definition and Overview Runout in machining is the deviation of a rotating tool or workpiece from its true axis. It can occur in various forms, including radial, axial, and face runout. Each type of runout Read more

As the name implies, aircraft interior decoration refers to the decorative parts inside the aircraft, which is the decoration of the interior space of the aircraft. Aircraft interior can be divided into cockpit interior and cabin interior according to the areas where the driver and passengers are located. The cabin interior is the soul and main body of the entire interior, including the ceiling, side wall panels, luggage compartments, compartment panels, door curtains, carpets, etc. in the cabin. What kind of lighting, seat style, and even the materials and installation methods used for the aircraft cabin cover all affect the interior effect and belong to the category of aircraft interior Read more

Many products must be manufactured to exacting standards. Questions like: Is it straight enough? How flat is it? How uniform must the wall thickness be? are not abstract. The specified acceptable range of deviation from a given dimension is called the tolerance. For many applications where aluminum extrusion will be part of a component assembly, dimensional tolerances are critical. Designers should understand the standard dimensional tolerances for commercially produced extrusions. Tight tolerances reduce productivity, leading to higher production costs. Judicious use of high tolerances only where productivity of the extrusion is critical will help control costs and deadlines. Here are six tips to help you use the most appropriate dimensions Read more

Five-axis linkage CNC machine tools are the foundation of high-end manufacturing and are widely used in aerospace, automotive, military and other fields. According to QY Research data, the global five-axis machine tool market will be worth US$7.48 billion in 2021, and is expected to reach US$13.8 billion in 2027 at a CAGR growth rate of approximately 10%. At present, the market share is mainly monopolized by international leading enterprises. The revenue scale and sales volume of domestic enterprises are far behind those of international leading enterprises, and there is huge room for the future. At present, the domestic aerospace and new energy automobile industries are in strong demand, which is Read more

When it comes to creating eye-catching and durable signage, there are a plethora of materials to choose from. Two popular options that often stand out are aluminum signs and acrylic signs. Each material has its own unique characteristics, advantages, and ideal use cases. In this article, we’ll explore the differences between aluminum and acrylic signs, helping you make an informed decision when it comes to your signage needs. Aluminum Signs Aluminum signs are renowned for their durability and longevity. These signs are constructed from sheets of aluminum, which are sturdy, lightweight, and corrosion-resistant. Here are some key benefits of aluminum signs: Weather Resistance: Aluminum signs can withstand the elements, making Read more

With the continuous advancement of technology, the aviation industry is also developing rapidly. As a key component of an aero-engine, the impeller plays a vital role. In order to improve the quality and performance of aviation impellers, machining technology is also continuously improved. This article will introduce the basic structure, machining technology and research progress of aviation impellers, and discuss the future development trend. Structure and function of aviation impeller The aviation impeller is one of the core components of the aero-engine. It is mainly used to guide the airflow into the engine and rotate it to generate thrust and lift. The impeller is made up of many fine blades, Read more

Generally, the metal 3D printing technology based on powder forming often has high requirements on the material and physical and chemical properties of its basic unit, the metal powder. Take the selective laser melting 3D printing technology as an example: on the one hand, due to the use of laser melting metal, it is difficult to form high reflectivity and non-weldable alloy materials; on the other hand, the use of powder tank powder supply technology requires high fluidity of metal powder, and generally coarser (particle size range 15-53 μm) spherical metal particles are used as forming materials for printing. The preparation process of spherical metal powder further increases the cost Read more

1. I have a question In mechanical design, we often use aluminum alloys. For example, 6061-T6 and 7075-T651 are the two most used aluminum alloys. Because they have a good weight-to-strength ratio, that is to say, they are light in weight and good in strength, so they are very popular, especially for weight-sensitive places, such as high-speed sports platforms, aircraft structures, bicycle racks, etc. So here comes the question, what is the difference between 6061-T6 and 7075-T651? What is the meaning of 6xxx and 7xxx? T6 VS T651? Having said that, I have to talk about the classification and naming of aluminum alloys. 2. Classification of aluminum alloy (1) Forged Read more

Aluminum alloy materials are widely used in medical equipment, aerospace, new energy vehicles, military industry and other industries. As its own unique advantages, such as low density, high specific strength and specific stiffness, and good corrosion resistance, it is one of the preferred processing materials for customers. Due to the wide application of aluminum alloy materials, its processing technology is becoming more and more mature, and aluminum alloy five-axis machining is one of them. For customers, aluminum alloy five-axis machining also has the following benefits: The Benefits Of Aluminum Alloy 5 Axis Machining For Customers First of all, aluminum alloy five-axis machining can greatly improve machining accuracy and quality. Compared Read more