Some customers have too much control over the cost of ordering the platform, and the cast iron plate is too light in weight. Attention should be paid to this kind of plate when machining, because if you are not careful, there will be chattering lines and chipping. There are two things you should pay attention to when using the tablet: 1. Cutting amount: When planing a thin standard cast iron plate, the cutting force and clamping force should be small, so a small cutting depth (about 0.3~0.5mm or less) and feed rate (about 0.1~0.5mm) should be used. 0.25mm/reciprocating stroke), as well as normal cutting speed, and appropriate cooling lubricant for Read more

Guide

Precision machine tools paired with advanced cutting tools provide outstanding metal cutting productivity. The tool holder, as the critical interface between the cutting tool and the machine tool spindle, is critical to achieving high productivity. Tool manufacturers offer a variety of toolholder types, each designed to perform optimally in specific machining applications. Therefore, a shop should choose a tool holder based on its specific process and the parts it produces. However, while shops want to use the most advanced machine tool technology and cutting tool materials, they often don’t pay much attention to the selection, application and maintenance of the holder that best suits their specific production needs. All Hilts Read more

Manufactured parts produced in the automotive and aerospace industries are becoming increasingly complex. Tolerances must meet relevant quality control standards, and today they are becoming increasingly complex and optimized. In addition, the customer is also requiring the supplier to implement compliance controls, whereas previously the compliance of batches was assessed using only input control samples. The above situation puts a lot of pressure on the quality control team. How should we deal with the ever-increasing tolerance pressures? This article will explore several possible solutions. In the automotive and aerospace industries, CNC Machining tolerances must meet quality control requirements, and tolerance requirements are constantly evolving. First, let’s understand the reasons for Read more

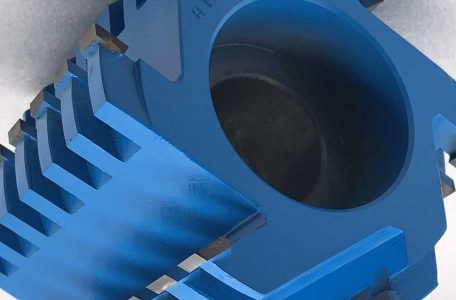

The spindle taper holes of machining centers are usually divided into two categories, namely the general system with a taper of 7:24 and the HSK vacuum system with a taper of 1:10. 1.7:24 Taper Universal Tool Holder Universal tool holders with a taper of 7:24 are generally available in five standards and sizes, namely NT (traditional), DIN 69871 (German standard), IS0 7388/1 (international standard), MAS BT (Japanese standard) and ANSI/ASME (American standard). The German standard of the NT type tool holder is DIN 2080. The tool holder is tightened by a pull rod on a traditional machine tool. It is also called ST in China; the other four tool holders Read more

Machining accuracy is the degree to which the actual size, shape and position of the surface of the machined parts conform to the ideal geometric parameters required by the drawings. The ideal geometric parameter, for the size, is the average size; for the surface geometry, it is the absolute circle, cylinder, plane, cone and straight line, etc.; for the mutual position between the surfaces, it is the absolute parallel , vertical, coaxial, symmetrical, etc. The deviation of the actual geometric parameters of the part from the ideal geometric parameters is called the machining error. The Introduction Of Cnc Machining Parts Machining accuracy is mainly used to produce products, and machining Read more

Today, there is a growing demand for orthopaedic replacement and rehabilitation devices. Medical parts include artificial joints as well as artificial boards, rods and nails used to repair or strengthen parts of the body that people have damaged following an accident or illness. With the general increase in human lifespan, more and more elderly people suffer from arthritis and osteoporosis, which leads to the growing demand for orthopaedic replacement devices. The global trend of weight gain and obesity puts more stress on human bones and joints. In addition, the lifestyles of most people are changing, from lack of physical activity to increased sports participation, further increasing the demand for replacement Read more

Gear mold laser surface strengthening technology refers to the use of high-energy density laser beams and coatings, or cladding materials to treat the surface of gears or molds in a numerically controlled environment to change the structure or composition of the surface layer to achieve surface phase change strengthening or Enhanced repair techniques. The phase change strengthening process has the advantages of good surface quality, and can control the hardness and the depth of the strengthening layer according to different materials, heat capacity of the workpiece, and different laser processing parameters. The technical factors that affect the strengthening effect in the traditional heat treatment process have changed a lot in Read more

How To Anodize Aluminum?The process of using aluminum or aluminum alloy products as anodes, placing them in an electrolyte solution for electrification treatment, and using electrolysis to form an aluminum oxide film on the surface is called anodizing treatment of aluminum and aluminum alloys. After anodic oxidation, an oxide film of several micrometers—hundreds of micrometers can be formed on the surface of aluminum. Compared with the natural oxide film of aluminum alloy, its corrosion resistance, wear resistance and decoration are obviously improved and improved. The principle of aluminum anodization is essentially the principle of water electrolysis. When the current is passed, the following reactions will take place: At the cathode, Read more

How To Weld Aluminum?Almost all welding methods can be used to weld aluminum and aluminum alloys, but aluminum and aluminum alloys have different adaptability to various welding methods, and each welding method has its own application. Gas welding and electrode arc welding methods are simple in equipment and easy to operate. Gas welding can be used for repair welding of aluminum sheets and castings that do not require high welding quality. Electrode arc welding can be used for repair welding of aluminum alloy castings. The inert gas shielded welding (TIG or MIG) method is the most widely used method for welding aluminum and aluminum alloys. Aluminum and aluminum alloy sheets Read more

It is understood that aluminum profiles are very common in today’s building materials market. As raw materials for building materials, they can not only produce a large number of commodities, but also have a great demand for construction projects. So, what kind of products can this material be made into? Aluminum profile manufacturers gave us the following answers. Workers from related manufacturers said that aluminum profiles are a kind of material with strong appearance and excellent seismic performance. of. Therefore, aluminum profiles are the raw materials for many products in the market, and they will have a larger development market. The application range of industrial aluminum profiles is getting wider Read more