Surface polishing of aluminum profiles is an important process in the processing of aluminum profiles, which can improve the durability and aesthetics of aluminum profile products, thereby enhancing the value and attractiveness of aluminum profile products. The following are the main categories of aluminum profile polishing processes and brief descriptions introduce. 1.Mechanical Polishing Mechanical polishing can produce a wide variety of surface finishes and textures, whether it’s a rough surface, a patterned matte look, or a classic mirror-gloss finish. Mechanical polishing can be achieved by various methods such as polishing, sanding, sandblasting, grinding or tumbling. If anodizing is required for aluminum extrusions, it must first be mechanically polished. This allows Read more

All posts in Aluminum Profiles Guide

Whether it is pure aluminum or aluminum products have a feature, that is, corrosion resistance. Due to this great advantage, it is widely used in many fields. Today we will discuss the reasons for the corrosion resistance of aluminum products. The chemical symbol for aluminum is AL, and it is a very active metal that ranks third on the periodic table of metals. It can easily react with oxygen in the air to form AL2O3 alumina. And aluminum oxide does not have obvious color like other metal oxides, it is colorless and transparent, and has no effect on the color of aluminum itself. More importantly, it can wrap the entire Read more

What are the causes of surface defects, dull color and rough surface of aluminum profiles? It can be mainly divided into two reasons. One is that the raw material aluminum ingots used are impure, and the profiles are extruded from aluminum rods doped with scrap aluminum. The second is caused by improper operation in the production process. The specific reasons are as follows: The raw materials used are doped with scrap aluminum Uneven ratio of raw materials in the production process During the production process, the acid content of the bath liquid is too high, and the acid corrosion causes the surface to be rough If the copper content in Read more

Aluminum profiles are alloy extrusion materials, and the normal surface color of aluminum profiles should be silver-white. The previous article introduced the reasons for the rough surface of industrial aluminum profiles. Here I will briefly talk about the reasons for the yellowing phenomenon that often occurs on the surface of the profile in addition to roughness and dullness. There are two main reasons for the yellowing of the surface of the profile. One is the improper cooling method during the extrusion process of the profile, and the other is the improper surface treatment of the profile. The specific analysis is as follows: The profile needs to be cooled after being Read more

There are stainless steel guardrails, iron guardrails, etc. The material used for the guardrail is different, and the effect is also different. Here is the industrial aluminum profile guardrail. What are the advantages of industrial aluminum profile fence? Aluminum alloy is light in weight: the weight of aluminum alloy is only one-third of that of iron, steel, and copper, but the hardness is several times that of them. Using aluminum alloy profiles as protective fences is not only easy to handle, but also cheaper to transport. High hardness of industrial aluminum profiles: The hardness of aluminum profiles can resist tensile force and large impact force, and its resistance is better Read more

1.Corrosion resistance The density of aluminum profiles is only 2.7g/cm3, which is about 1/3 of the density of steel, copper or brass (7.83g/cm3, 8.93g/cm3, respectively). Aluminum exhibits excellent corrosion resistance under most environmental conditions, including in air, water (or brine), petrochemicals, and many chemical systems. 2.Conductivity Aluminum profiles are often chosen due to their excellent electrical conductivity. On an equal weight basis, the conductivity of aluminum is approximately 1/2 that of copper. 3.Thermal conductivity The thermal conductivity of aluminum alloys is about 50-60% of that of copper, which is beneficial for the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and automobile cylinder heads and radiators. 4.Non-ferromagnetic Aluminium profiles Read more

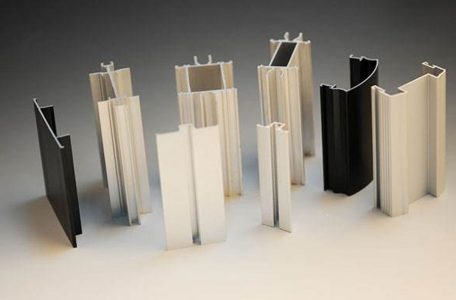

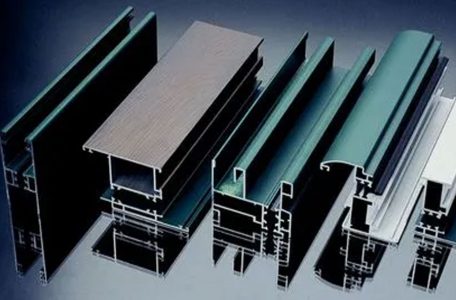

Industrial aluminum profiles are also known as industrial aluminum extrusions and industrial aluminum alloy profiles. Industrial aluminum profiles are alloy materials with aluminum as the main component. Aluminum rods are hot-melted and extruded to obtain aluminum materials with different cross-sectional shapes. The proportion of the alloy is different, and the mechanical properties and application fields of the industrial aluminum profiles produced are also different. Today we will talk about the three principles that customers follow when purchasing industrial aluminum profiles. 1.Very Cheap Do Not Choose The explanation is as follows: aluminum profile cost = spot price of aluminum ingot + processing fee of extruded aluminum profile + packaging material fee Read more

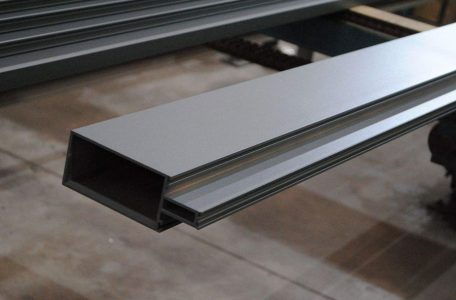

Aluminum profile products have the characteristics of high strength, light weight, strong corrosion resistance, convenient assembly, material saving and durability, but unreasonable maintenance, installation and maintenance will also affect the beautiful appearance and surface color of aluminum profile products. Therefore, there should be correct maintenance and maintenance methods. During the handling process of aluminum profiles, they must be handled with care to prevent surface bumps caused by bumps and affect the appearance of the surface; During transportation, aluminum profiles must be covered with sheet cloth to prevent the intrusion of rain and snow; The storage environment of aluminum profiles should be dry, bright, well ventilated, and non-corrosive climate, and at Read more

Scratch grooves on the surface of aluminum profiles are a very common surface defect, mostly caused by foreign objects stuck to the mold or rough machining at the empty knife. There is also a raised scratch at the corner of the product, which is caused by the crack of the extrusion die, and the lateral scratch or scratch is mainly due to the hard surface on the cooling bed when the product is transported laterally from the sliding table to the finished sawing table. The protruding objects will scratch the product, and some are produced during loading and handling. The main elimination methods are: The working belt of the extrusion Read more