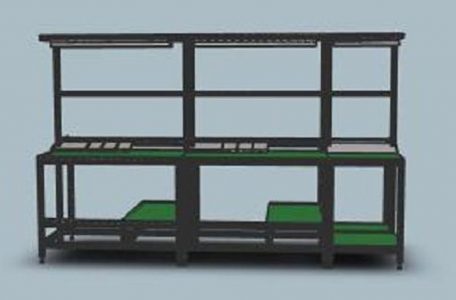

Industrial aluminum profile storage shelves are generally customized according to customer needs, and need to be developed and customized in combination with the shape, structure and weight of the stored items. Different specifications of industrial aluminum profiles are selected according to demand and bearing capacity. Aluminum profile storage shelves are customized products according to the needs of customers. We mainly consider the following aspects to customize the use environment: 1: Bearing capacity: The aluminum profile shelf first needs to consider the maximum load carrying capacity of the shelf. The carrying capacity determines the stability of the shelf during use. Under the condition of overloading for a long time, the stability Read more

All posts in Aluminum Profiles Guide

The function and characteristics of aluminum profile wire ducts are believed to be understood by everyone. Recently, many small partners have responded that they do not know how to install aluminum alloy wire ducts. In fact, as long as you know these four steps to install aluminum profile wire ducts, it is easy to install Not difficult. Today, the editor will talk about the four steps of installing aluminum profile trunking! Steps to install aluminum profile trunking: Step 1: Measure the size, use an angle grinder or a small cutting machine to cut two 45-degree beveled butt joints at the corners Step 2: Use an electric drill to fix the Read more

We all know that aluminum profile products are very popular now, because the aluminum profile link only needs connecting parts, no welding is required, whether it is installed or disassembled, it is more convenient, so what kind of connectors do aluminum profiles have, and how should they be classified? First of all, according to the difference in the connection methods of aluminum profiles, we divide the connectors of aluminum profiles into external connectors and internal connectors: Internal connectors mainly include: 1. Angle groove connectors: divided into angle groove connectors for profiles and angle groove connectors for auxiliary profiles 2. Built-in connectors: the length of the bolts used is determined by Read more

Many people want to customize equipment cabinets with aluminum profiles, but don’t know how to customize them? In fact, the process is very simple, because many steps are completed in the profile manufacturer, and the customer only needs to provide some drawings or size data. We need to draw our own customized equipment cabinet drawings, hand-painted sketches are enough, and then find a reliable aluminum profile manufacturer, tell the technical staff the specific drawings and details, help to issue 3D drawings, and confirm the specific details. , after there is no problem, you can sign the contract and pay, and finally wait for the receipt. In the process of customization, Read more

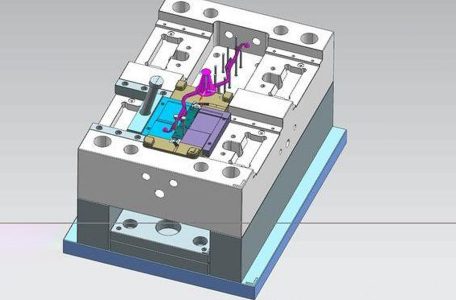

For industrial aluminum profiles, due to the loss of center symmetry of many of their sections, the section of the cut aluminum ingot billet has no similarity with the section of industrial aluminum profiles. At the same time, the wall thicknesses of most industrial aluminum profiles are different. Compared with aluminum pipes and aluminum bars, the metal flow uniformity of profiles is worse. The job of mold designers and engineers and technicians is to take various measures to minimize the non-uniformity of metal flow, to achieve coordinated and uniform flow of various parts as much as possible, and to ensure the basic uniformity of industrial aluminum products. Technical measures to Read more

According to the billet temperature, extrusion can be divided into three types: hot extrusion, cold extrusion and warm extrusion. Extrusion when the metal billet is above the recrystallization temperature (plastic deformation) is hot extrusion; extrusion at normal temperature is cold extrusion; extrusion above normal temperature but not exceeding the recrystallization temperature is warm extrusion. 1. Hot Extrusion It is widely used in the production of pipes and profiles of non-ferrous metals such as aluminum and copper, and belongs to the scope of metallurgical industry. Hot extrusion of steel is used both to produce special pipes and profiles, as well as to produce carbon and alloy steel parts that are difficult Read more

Electro coating is a coating method in which particles such as pigment and resin suspended in electrophoresis solution are directionally migrated and deposited on the substrate surface of one of the electrodes by using an external electric field. The principle of electrophoretic coating was invented in the late 1930s, but the development and industrial application of this technology was after 1963. Electrophoretic coating is a special film forming method developed in recent 30 years, which is the most practical construction process for waterborne coatings. With the characteristics of water solubility, non-toxic and easy automatic control, it has been widely used in automobile, building materials, hardware, household appliances and other industries. Read more

When the aluminum profile is pressurized, if there is air left in the aluminum profile, it will cause air bubbles inside and on the surface of the aluminum profile, making the aluminum profile become waste. Therefore, in order to prevent air from entering the aluminum profile, it is necessary to find out why the air is brought in. The following small series introduces the main methods of residual air inside the four extruded aluminum profiles. The hot shearing of the long rod leads to the residue of air. The shear plane formed when the rod is thermally sheared is absolutely not perfect and vertical. The simple thermal shearing of long Read more

The industrial aluminum profile is corrosion-resistant, has a beautiful surface, and has a wide range of applications. The surface of the aluminum profile is a natural silvery white, which is very beautiful. However, there are also some industrial aluminum profiles that will turn black and dark on the surface, which greatly affects the aesthetics of the equipment. Today we will analyze the reasons for the blackening of the surface of industrial aluminum profiles. Material problem. Some industrial aluminum profiles turn black and dark as soon as they are bought. This should be a material problem. The iron content in the aluminum alloy exceeds the standard, and some are smelted with Read more

Chemical polishing is an important method of polishing the surface of aluminum profiles. Chemical polishing is a method of eliminating wear marks and etching and leveling by the selective dissolution of chemical reagents on the uneven area of the sample surface. What are the main factors that affect the chemical polishing effect of aluminum profiles? The purity of aluminum profile aluminum is too low. When the purity of aluminum in the aluminum profile is too low, it is not suitable for chemical polishing, and it is changed to nickel plating or chrome plating under possible conditions. There is dirt on the surface of the aluminum profile. Before the aluminum-aluminum profile Read more