In the cnc machining process of making prototype samples, we will come into contact with various parts, which means that there are different post-processing requirements. Anodizing is one of them. Today we will introduce this process. Anodizing is a kind of electrolytic oxidation. In this process, the surface of aluminum alloy is usually transformed into an oxide film. This film has protective, decorative and other functions. It is divided into aluminum alloy hard anodizing and ordinary aluminum alloy anodized. The Detail Of Anodizing Aluminum Cnc Prototype Parts Process Mechanical polishing – degreasing – alkali washing – acid washing – chemical polishing – anodizing – dyeing – sealing – mechanical brightening; Read more

Guide

When you finish CNC machining a part, your job isn’t done. These raw components may have unsightly surfaces, may not be strong enough, or are just part of one component that must be joined with other components to form a complete product. After all, how often do you use a device made up of individual parts? The point is that post-processing processes are necessary for a range of applications, and here we introduce you to some considerations so that you can choose the right secondary operation for your project. In this three-part series, we’ll cover options and considerations for heat treatment processes, finishes, and hardware installation. Any or all of Read more

1. Minimize the number of parts Find ways to combine parts. For example, many electronic equipment enclosures use living hinges instead of knuckle hinges. When routing, choose a molded guide feature, or use a thermoformed guide (like the old LazerTag gun). Speaking of minimizing parts count… 2. Built-in fasteners Where possible, build assembly features directly into the part instead of using screws. Snap fits are generally equally secure and can be assembled without tools. Sometimes screws are necessary, but sparing the use of fasteners can consume up to 50% of assembly labor. One thing to note: Snap fits can add to the cost of the injection mold, so be sure Read more

In the current automobile production, more and more attention is paid to quality inspection. The auto manufacturing industry faces rising competitive pressures and stricter legal regulations. In order to avoid costly recalls, etc., the development of automobile manufacturing has to be considered from many aspects. For example, more than 1.9 million vehicles were recalled in Germany in 2014 alone, according to the Centre for Automotive Management (CAM). Faced with this situation, manufacturers in various fields have to step up to improve their production process, especially the production process of improving the engine structure. The crankshaft is a prime example: this core component will have to assume greater stability in the Read more

The original error reduction method when machining the floor boring machine table: If errors are found during production, the main factors that affect the machining errors should be found first, and then find ways to eliminate or reduce these factors. Original error compensation method: artificially create a new error to offset the original error in the process system. When the original error is negative, the artificial error will take a positive value, otherwise, take a negative value, and try to make the two larger equal. Original error transfer method: The original error of the process system can be transferred to the insensitive direction of the machining error or other aspects Read more

There are many product categories for aluminum alloy processing. Today, high-strength aluminum alloys generally refer to super-hard aluminum alloys of the aluminum-zinc-magnesium-copper-aluminum alloy series. High-strength aluminum alloys are aluminum alloys with a strength greater than 480 MPa. The demand for this kind of aluminum alloy is also increasing, so that the processing technology of high-strength aluminum alloy is also gradually being studied. The Application Field Of Aluminum Alloy All kinds of aircraft use aluminum alloy as the main structural material. Skins, beams, ribs, stringers, bulkheads, and landing gear on aircraft can all be made of aluminum alloys. The amount of aluminum used in the aircraft varies according to its purpose. Read more

When the aluminum profile is pressurized, if there is air left in the aluminum profile, it will cause air bubbles inside and on the surface of the aluminum profile, making the aluminum profile become waste. Therefore, in order to prevent air from entering the aluminum profile, it is necessary to find out why the air is brought in. The following small series introduces the main methods of residual air inside the four extruded aluminum profiles. The hot shearing of the long rod leads to the residue of air. The shear plane formed when the rod is thermally sheared is absolutely not perfect and vertical. The simple thermal shearing of long Read more

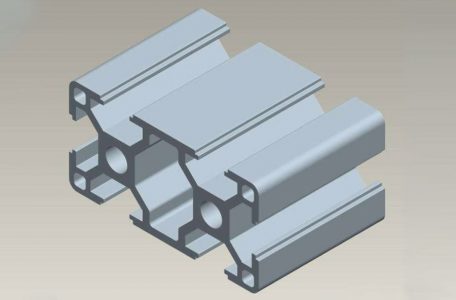

The industrial aluminum profile is corrosion-resistant, has a beautiful surface, and has a wide range of applications. The surface of the aluminum profile is a natural silvery white, which is very beautiful. However, there are also some industrial aluminum profiles that will turn black and dark on the surface, which greatly affects the aesthetics of the equipment. Today we will analyze the reasons for the blackening of the surface of industrial aluminum profiles. Material problem. Some industrial aluminum profiles turn black and dark as soon as they are bought. This should be a material problem. The iron content in the aluminum alloy exceeds the standard, and some are smelted with Read more

Chemical polishing is an important method of polishing the surface of aluminum profiles. Chemical polishing is a method of eliminating wear marks and etching and leveling by the selective dissolution of chemical reagents on the uneven area of the sample surface. What are the main factors that affect the chemical polishing effect of aluminum profiles? The purity of aluminum profile aluminum is too low. When the purity of aluminum in the aluminum profile is too low, it is not suitable for chemical polishing, and it is changed to nickel plating or chrome plating under possible conditions. There is dirt on the surface of the aluminum profile. Before the aluminum-aluminum profile Read more

Surface polishing of aluminum profiles is an important process in the processing of aluminum profiles, which can improve the durability and aesthetics of aluminum profile products, thereby enhancing the value and attractiveness of aluminum profile products. The following are the main categories of aluminum profile polishing processes and brief descriptions introduce. 1.Mechanical Polishing Mechanical polishing can produce a wide variety of surface finishes and textures, whether it’s a rough surface, a patterned matte look, or a classic mirror-gloss finish. Mechanical polishing can be achieved by various methods such as polishing, sanding, sandblasting, grinding or tumbling. If anodizing is required for aluminum extrusions, it must first be mechanically polished. This allows Read more