CaO, MgO, SiO2 and transition metal and rare earth metal oxides are commonly used as additives in 95 porcelain. It can be fired at a lower temperature, and there are generally 10% (volume) glass phase and subcrystalline phase in the microstructure. In the CaO-AI2O3_ _SiO2 system phase diagram, the lowest eutectic phase temperature is 1495 ° C. When the ratio of SiO2/CaO in the porcelain composition is <2.16, the minerals that coexist with corundum are anorthite and calcium hexaaluminate; and when SiO2/CaO>2.16, corundum will coexist with mullite and anorthite. The advantages of the MgO-AI2O3-SiO2 system are good acid resistance and fine grains in the structure, but the sintering temperature is Read more

Guide

The melting point of aluminum is 660° Celsius. Aluminum is an active metal, and a dense oxide film about 50 angstroms thick is immediately formed on the surface of aluminum in dry air, so that aluminum will not be further oxidized and can be resistant to water; but aluminum powder is easily combustible when mixed with air; molten aluminum can be mixed with Water reacts violently; aluminum is amphoteric, easily soluble in strong bases, and also soluble in dilute acids. The characteristics of aluminum are as follows: Aluminum is a silver-white light metal, relatively soft, with a density of 2.7 grams per cubic centimeter, a melting point of 660.4 degrees, Read more

In recent years, with the continuous maturity of oxidation aluminum parts technology, its application field has been further expanded, and gradually extended to various industries including ceramic machining products. In recent years, with the rapid development of the ceramic industry, a large number of ceramic composite materials have been used in many projects. In addition, alumina, as a very important component in ceramic materials, has a very wide range of applications. This is mainly determined by the properties of alumina materials. Alumina not only has strong hardness, but also has very stable chemical properties. In addition, alumina also has the characteristics of high wear resistance and high melting point. Because Read more

The Process Measures To Reduce Deformation Of Aluminum Machining 1. Reduce the internal stress of the blank Natural or artificial aging and vibration treatment can partially eliminate the internal stress of the blank. Pre-processing is also an effective process method. For larger blanks, due to the large allowance, the deformation after aluminum precision cnc machining is also large. If the excess part of the blank is pre-processed and the allowance of each part is reduced, it can not only reduce the cnc machining deformation of the subsequent process, but also release a part of the internal stress after pre-processing for a period of time. For example, the picture above shows Read more

With the repetition of the global epidemic, we must pay attention to the processing of mask machine parts. When processing parts, cracks will appear in the parts. The source of the cracks is brought by the abrasive tools in the R&D and design process. No material can be completely without drawbacks. , but the quantity and degree are different. Although we have made efforts in technical operation and other aspects, there are still more disadvantages than metal materials. Also, this does not mean that products with shortcomings will inevitably cause cracks, mainly The thing is that the product is not easy to plastically deform like a metal under the action Read more

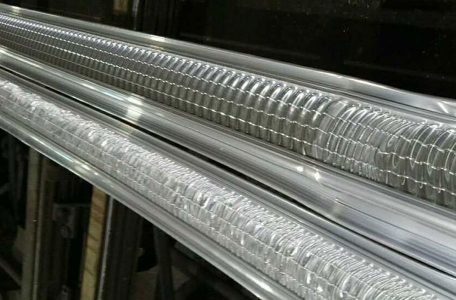

How important is the role of aluminum extrusion die for aluminum products? It can be said that it plays a vital role in the extrusion process of aluminum profiles and directly affects the quality of aluminum profiles!Then follow us to learn about some problems that we may cause during the die extrusion process in the production of aluminum. The First Is The Problem Of Seam Angle Or Poor Welding There are only two reasons for this problem, the first is that the orifice is small, the metal flow in the welding cavity is not enough to make the metal without sufficient hydrostatic pressure in the welding chamber, the product does Read more

Shortening At the tail end of some extruded products, after low magnification inspection, there is a horn-like phenomenon in the middle part of the cross section, which is called shrinking tail. Generally, the tail of the forward extrusion product is longer than that of the reverse extrusion, and the soft alloy is longer than the hard alloy. The shrinkage of the forward extruded product is mostly in the form of an annular disjoint layer, and the shrinkage of the reverse extruded product is mostly in the shape of a central funnel. The metal is extruded to the back end, and the ingot skin and foreign inclusions accumulated on the dead Read more

The quenched aluminum workpiece is reheated to an appropriate temperature lower than the lower critical temperature Ac1 (the starting temperature of pearlite to austenite transformation during heating), and the metal heat treatment is cooled in air or water, oil and other media after holding for a period of time craft. Or heat the quenched aluminum alloy workpiece to an appropriate temperature, hold it for a period of time, and then cool it slowly or rapidly. Generally used to reduce or eliminate internal stress in quenched steel, or reduce its hardness and strength to improve its ductility or toughness. The quenched aluminum workpiece should be tempered in time, and the required Read more

Aluminum alloys can be divided into two categories: cast aluminum alloys and deformed aluminum alloys according to their composition and process properties. Deformed aluminum alloys are divided into four categories according to their performance and process performance: rust-proof aluminum, hard aluminum, super-hard aluminum and forged aluminum. 1. Anti-Rust Aluminum The main alloying elements of rust-proof aluminum are manganese and magnesium, which belong to Al-Mn and Al-Mg system alloys. This kind of aluminum alloy belongs to the aluminum alloy that cannot be strengthened in time. After forging and annealing, it is a single-phase solid solution with high corrosion resistance and good plasticity. Manganese can improve the strength of aluminum alloy in Read more

This article mainly focuses on the maintenance work of the aluminum alloy high-speed boat hull, and the marine electrical and navigation equipment should be implemented in accordance with the operating instructions. Aluminum alloy boats have many excellent advantages, one of which is low maintenance costs. Easy maintenance and low cost does not mean no maintenance is required. In order to improve the efficiency of operation and reduce costs, it is necessary to work hard on the maintenance of equipment. The paint peeling of aluminum alloy boats below the waterline is a common problem, and it is also the most troublesome problem for ship owners. This is mainly due to the Read more