Aluminum heat treatment cutting machine has a lot to do with material characteristics, processing temperature and processing speed, and the effect of different processing methods is obviously different. Aluminum profile cutting machine two kinds of mechanical tools specially used for aluminum cutting and blanking. The machine is used for cutting aluminum rods, aluminum plates, aluminum tubes, and aluminum profiles. The aluminum sawing machine is a device composed of a single-phase series excitation motor, a reduction mechanism, a splint, a power switch, and a casing. The aluminum sawing machine is also called the aluminum intermediary machine. The alloy saw blade is specially used for cutting various aluminum materials, and the cutting Read more

Guide

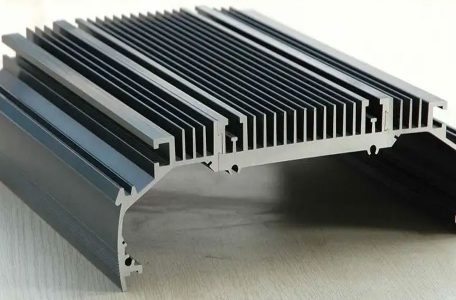

Let’s look at the characteristics of aluminum profiles first: aluminum profile radiators are also called radiator aluminum profiles or sunflower aluminum profiles. Aluminum profile radiators have the characteristics of beautiful appearance, light weight, good heat dissipation performance, and good energy-saving effect. In addition, the decorative performance of aluminum profiles is very strong: when aluminum profiles are used for decoration or some specific occasions, the surface needs to be anodized, painted, etc. to obtain the corresponding color and surface structure, and the corrosion resistance of aluminum profiles is relatively high. Good, its anodizing performance, surface treatment performance, coating performance are very good. In my country, aluminum radiators are widely used in Read more

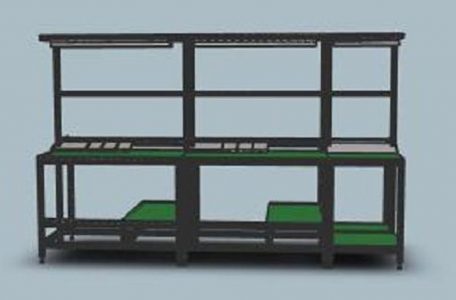

Industrial aluminum profile storage shelves are generally customized according to customer needs, and need to be developed and customized in combination with the shape, structure and weight of the stored items. Different specifications of industrial aluminum profiles are selected according to demand and bearing capacity. Aluminum profile storage shelves are customized products according to the needs of customers. We mainly consider the following aspects to customize the use environment: 1: Bearing capacity: The aluminum profile shelf first needs to consider the maximum load carrying capacity of the shelf. The carrying capacity determines the stability of the shelf during use. Under the condition of overloading for a long time, the stability Read more

The function and characteristics of aluminum profile wire ducts are believed to be understood by everyone. Recently, many small partners have responded that they do not know how to install aluminum alloy wire ducts. In fact, as long as you know these four steps to install aluminum profile wire ducts, it is easy to install Not difficult. Today, the editor will talk about the four steps of installing aluminum profile trunking! Steps to install aluminum profile trunking: Step 1: Measure the size, use an angle grinder or a small cutting machine to cut two 45-degree beveled butt joints at the corners Step 2: Use an electric drill to fix the Read more

We all know that aluminum profile products are very popular now, because the aluminum profile link only needs connecting parts, no welding is required, whether it is installed or disassembled, it is more convenient, so what kind of connectors do aluminum profiles have, and how should they be classified? First of all, according to the difference in the connection methods of aluminum profiles, we divide the connectors of aluminum profiles into external connectors and internal connectors: Internal connectors mainly include: 1. Angle groove connectors: divided into angle groove connectors for profiles and angle groove connectors for auxiliary profiles 2. Built-in connectors: the length of the bolts used is determined by Read more

Many people want to customize equipment cabinets with aluminum profiles, but don’t know how to customize them? In fact, the process is very simple, because many steps are completed in the profile manufacturer, and the customer only needs to provide some drawings or size data. We need to draw our own customized equipment cabinet drawings, hand-painted sketches are enough, and then find a reliable aluminum profile manufacturer, tell the technical staff the specific drawings and details, help to issue 3D drawings, and confirm the specific details. , after there is no problem, you can sign the contract and pay, and finally wait for the receipt. In the process of customization, Read more

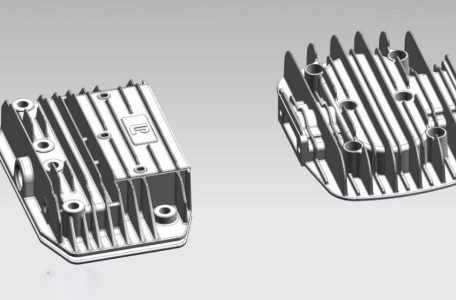

For industrial aluminum profiles, due to the loss of center symmetry of many of their sections, the section of the cut aluminum ingot billet has no similarity with the section of industrial aluminum profiles. At the same time, the wall thicknesses of most industrial aluminum profiles are different. Compared with aluminum pipes and aluminum bars, the metal flow uniformity of profiles is worse. The job of mold designers and engineers and technicians is to take various measures to minimize the non-uniformity of metal flow, to achieve coordinated and uniform flow of various parts as much as possible, and to ensure the basic uniformity of industrial aluminum products. Technical measures to Read more

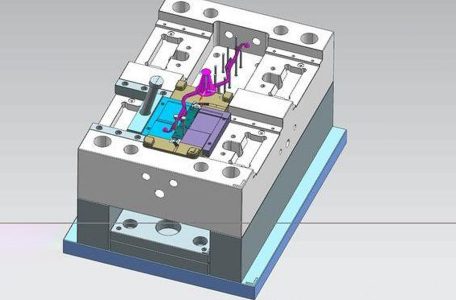

In the process of starting production of aluminum die-casting molds, the mold must be preheated to prevent the appearance of cracks caused by the sudden encounter of hot metal liquid in the cold mold. For more complex molds, blowtorch, liquefied gas, and good conditions With a mold temperature machine, relatively simple molds can be preheated by slow injection. If the mold is equipped with neutron control, pay attention to prohibit the signal line between the die-casting machine and the mold from having joints. The reason is very clear. In daily production, it is difficult to avoid water on the signal line, or the joints are easily broken. , resulting in Read more

According to the billet temperature, extrusion can be divided into three types: hot extrusion, cold extrusion and warm extrusion. Extrusion when the metal billet is above the recrystallization temperature (plastic deformation) is hot extrusion; extrusion at normal temperature is cold extrusion; extrusion above normal temperature but not exceeding the recrystallization temperature is warm extrusion. 1. Hot Extrusion It is widely used in the production of pipes and profiles of non-ferrous metals such as aluminum and copper, and belongs to the scope of metallurgical industry. Hot extrusion of steel is used both to produce special pipes and profiles, as well as to produce carbon and alloy steel parts that are difficult Read more

Strong Oxidation Capacity The affinity between aluminum and oxygen is very strong. It is easy to combine with oxygen in the air to form a dense and solid Al2O3 film with a thickness of about 0.1 μ m. The melting point is as high as 2050 ℃, far exceeding the melting point of aluminum and aluminum alloys, and the density is very large, about 1.4 times that of aluminum. In the welding process, alumina film will hinder the good bonding between metals and easily cause slag inclusion. The oxide film will also absorb water, which will promote the formation of pores in the weld during welding. These defects will reduce Read more